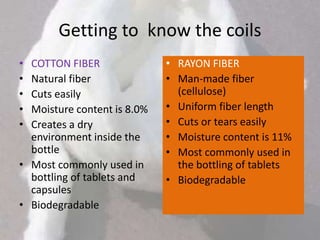

Pharmaceutical coils made from cotton, rayon, or polyester fibers provide protection for bottled pharmaceutical products. Cotton coils create a dry environment and are commonly used for tablets and capsules. Rayon coils have uniform fibers and are also used for tablets. Polyester coils are non-absorbent and prevent moisture transfer, making them suitable for soft gel capsules. Pharmaceutical coils ensure stability during shipping and storage of medicines. SORBEAD INDIA supplies different sizes of pharmaceutical coils at affordable prices to the pharmaceutical industry.