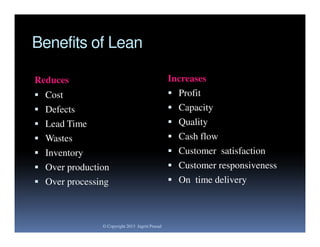

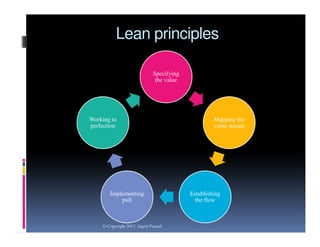

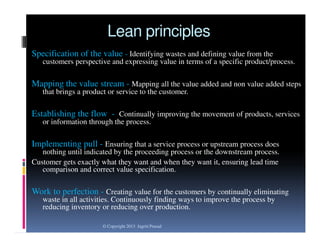

Lean is a management philosophy focused on improving processes by eliminating waste and maximizing customer value with fewer resources. Originating from the Toyota Production System, it identifies types of waste and employs principles such as mapping the value stream and implementing pull systems to enhance efficiency. The ultimate goal of lean is continuous improvement and delivering exactly what customers want while reducing costs and increasing satisfaction.