The document outlines the steps for designing the thickness of cement concrete (CC) pavement according to IRC guidelines, emphasizing parameters such as design axle load, temperature differential, and supporting layer properties. It details a trial-and-error approach to determining pavement thickness by checking stress ratios against flexural strength and cumulative fatigue damage. Additionally, the document discusses the design of dowel bars for load transfer at joints, highlighting considerations for bearing stress and structural integrity.

![480 DESIGN OF 1-llGHWAY PAVEMENT

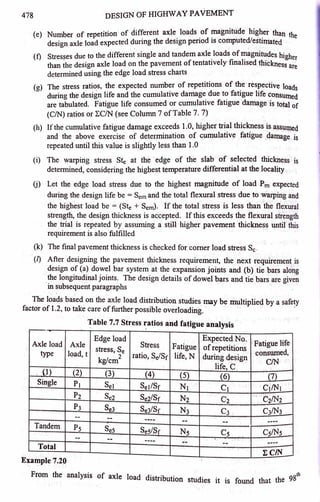

Since total fatigue life consumed or cumulative_ fati~e damag~ due ~o axle loads

exceeding design load is only 0.033 or 3.3 % of f~ttgue hfe ~e d_eSlgn t~ckness of24

cm is safe due to repeated application ofloads durmg the design hfe.

Warping stress:

Temperature differential, t for 24 cm pavement thickness (by interpolation) = 17.24 °c

Length ofslab, Lx = 4.2 m = 420 cm, thickness, h = 24 cm, K

3

= 30 kg/cm

Assuming E = 3 x 105

kg/cm

2

, Poisson's ratio,µ= 0.15

Radius ofrelative stiffness, I = [ Eh3 ]

114

12K(l-µ2

)

= 58.6 cm (substituting the ~alues)

Corresponding to Lx = 420 cm, Lxf/ = 420/58.6 =7.17; from

warping stress coefficient chart (Fig. 7.20),

Cx =0.98

Corresponding to LJI = 350/58.6 = 5.97, Cy= 0.9

Considering higher ofthe two values, adopt warping stress coefficient of0.98.

Therefore maximum warping stress at pavement edge,

Ste =

Total stress

Cx Eet = (0.98 x 3 x 105

x 1 x 10-5

x 17.24)/2

2

2

= 25.34 kg/cm

Highest load stress at pavement edge · = 21.5 kg/cm

2

Total (load stress+ warping stress) at edge = 46.84 kg/cm

2

As the total stress exceeds the flexural strength of 45 kg/cm

2

, the design is to be

revised, assuming a higher pavement thickness in order to fulfil this criterion.

In trial no. 2, assume pavement thickness h = 30 cm

Radius ofrelative stiffness, (substituting the values) l = [ Eh

3

]

114

= 69.27 cm

· 12K(l-µ2)

Highest edge load stress due to single axle load of 16 t for h == 30 cm (from Fig. 7.25)

= 15.3 kg/cm

2

Temperature differential, t for pavement thickness of 30 cm (by interpolation== 18.0 °C

Lxf/ = 420/69.27 = 6.06, Cx =0.90

Maximum warping stress at edge = (0.90 x 3 x 105

x 1 x 10-s x 18.0)/2 = 24.3 kg/cm

2

Total (load stress + tarping stress) = 15.3 + 24.3 = 39.6 kg/cm2, less than flexural

strength of45 kg/cm , hence safe.](https://image.slidesharecdn.com/pd-m4-rpdesign-240619105915-3505d4f1/85/Pavement-Design-Rigid-Pavement-Design-pdf-4-320.jpg)

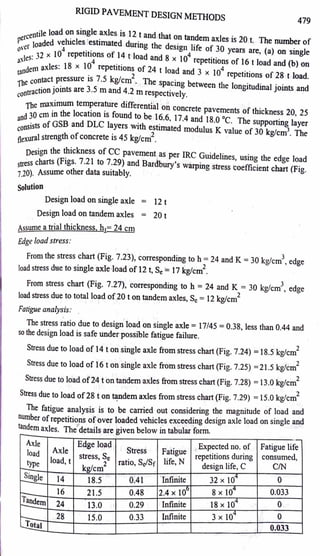

![RIGID PAVEMENT DESIGN METHODS 481

The factor of safety available for the maximum stress d t th hi h

· - 45139 6 - 1 1 ue O e g est load and

warping stress - · - • 4, may be accepted

Check for comer load stress, Sc = !~[1-(a-;2r2

]

Substituting design load P = 16 / 2 =8.0 t =8,000 kg h =30 / =69 27

3

== J(8000/ 7.5,r) = 18.43 cm ' cm, · cm,

Substituting, the values in the equation Sc= 18 4 kg/cm2 and so th d · · "

. , • e es1gn 1s sa1e.

Adopt design thickness ofCC pavement =30 cm

7.9.4 De~ign ofDowel Bars at Load Transfer Joints

Objectiv~s of dowel bars

As mentioned in Art. 7.6.3, expansion joints and construction joints are formed as

thro~gh joints acr~ss ~~ full depth of the slab. A small gap of about 20 mm is

provided at expans10~ JOmts to allow for expansion of long CC pavement slabs during

s~er seaso~. This gap or joint width helps to relieve the compressive stresses

dunng expansion and also helps to prevent buckling of the slab near the joint Steel

dowel bars are embedded at mid depth during construction as specified in the design in

order to strengthen these weak locations and to provide desired load transfer to the

adjoining slab across the joint. Though it is not considered very essential to provide

expansion joints in CC pavements at regular intervals, they should invariably be

provided wh~re the pavement is designed to abut structures like b~dges. /

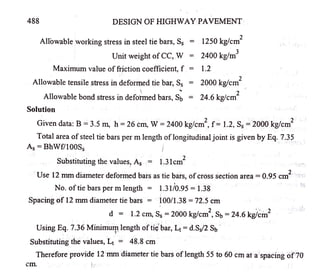

Functioning

Figure 7.30 (a) illustrates that there is no load transfer across the expansion joint

without dowel bars as each slab deflects independently under the axle load. The

functioning of an expansion joint with dowel bar is illustrated in Fig. 7.30 (b). When

wheel load is placed at the edge ofthe slab adjoining the expansion joint, a part ofthe

deflection and load are transferred across to the adjoining slab with the help ofa group

ofdowel bars. The load stress diagram in dowel bar is shown in Fig. 7.30 (c).

Rounded steel bars ofdiameter 25 to 32 mm and length about 500 mm are placed at

intervals of 250 to 300 mm as per the design. About 50 mm less t1ian half lengtli of

. the rounded steel dowel bars are embedded during concreting along one slab, so as to

develop bond with the concrete. The other halflength ofthe dowel bars (plus 50 mm)

are covered with a suitable plastic sheathing to prevent development ofbond between

the dowel bars and the concrete of the adjoining slab. This de-bonded half length of

the dowel bars can slide into the adjoining slab. The construction details are given in

Art. 8.5.5 of Chapter 8, 'Highway Construction'.

Stresses in dowel bars

The maximum bearing stress developed in the.dowel bar.and the allowable bearing

stress in cement concrete are to be considered dunng the design.

Maximum bearing stress

The bearing stress between concrete and dowel ba~ depends ~inly on diameter of

the dowel bar and spacing between them. The maximum beanng stress between the

concrete and the dowel bar is given by the equation:](https://image.slidesharecdn.com/pd-m4-rpdesign-240619105915-3505d4f1/85/Pavement-Design-Rigid-Pavement-Design-pdf-5-320.jpg)

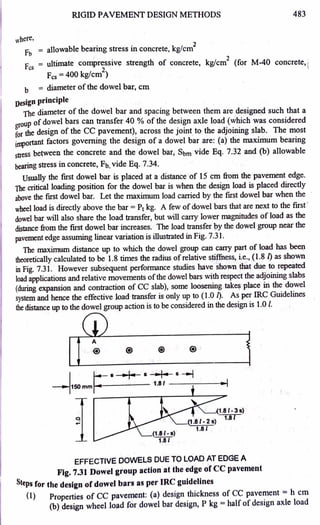

![RIGID PAVEMENT DESIGN METHODS

485

Elastic modulus of dowel bar steel, Es = 2 x 1'06 kg/cm2,

modulus ofdowel - concrete interaction, u = 41 500 kg/ J d • • .dth

1

• "'"C , cm an Jomt w1 z = .8 cm

Design load (98t11 percentile axle load) on single axle ~ 12,000 kg

Therefore design wheel load for dowel bar design, p =

6000

kg

Total load to be sustained by dowel g.roup

= 0,4 p =0,4 X 6000

= 2400 kg

Let the maximum load s~stained by the first dowel bar near the edge = P1 kg

Assume diameter of dowel bar b = 3 ocm and sp · b

in the first trial , . acmg etween dowel bars, s =25 cm

Substituting the relevant values,

Moment of inertia of dowel bar, I = (7rb4/64) cm4 =3_

976 cm4

Allowable bearing stress in conc_

rete is calculated using Eq. 7.34

ie., Fb = Fcs (10.16- b)/9,525 = 300.7 kg/cm2

T~tal ~oad transferre~ by the dowel group for the assumed dowel diameter and

spacmg m terms of maximum load carried,

Pt = P1 {l +(/-s)//+(/-2s)//+(/ - 3s)//+---}

= Pt Y = Pt {l + (62.2-25)/62.2 + (62.2-50)/62.2} = 1.794 P1

= 2400

Pt = 2400/1.794 = 1337.8 kg

Relative stiffness of the dowel bar embedded·in concrete, p=(Mcb/4 El)o.25 cm

(substituting the relevant values from above) = 0.25

Check for maximum bearing stress between concrete and the dowel bar sustaining

load Pt(vide Eq. 7.32), Sbm = McPt (2 + Pz)/4 p3

E5I = (substituting the relevant

. 2

values from above)= 273.7 kg/cm .

As the maximum bearing stress between concrete and the dowel bar (273.7 kg/en/)

is less than the allowable bearing strength in concrete (300.7 kg/cm

2

) the dowel bar

design is safe and therefore may be accepted. Rounded dowel bars of diameter 3.0 cm

and spacing 25 cm may. be provided at expansion joints.

(Note: In case it is necessary to reduce some quantity of steel, the trial may be repeated assuming

ahigher spacing of 27 or 30 cm)

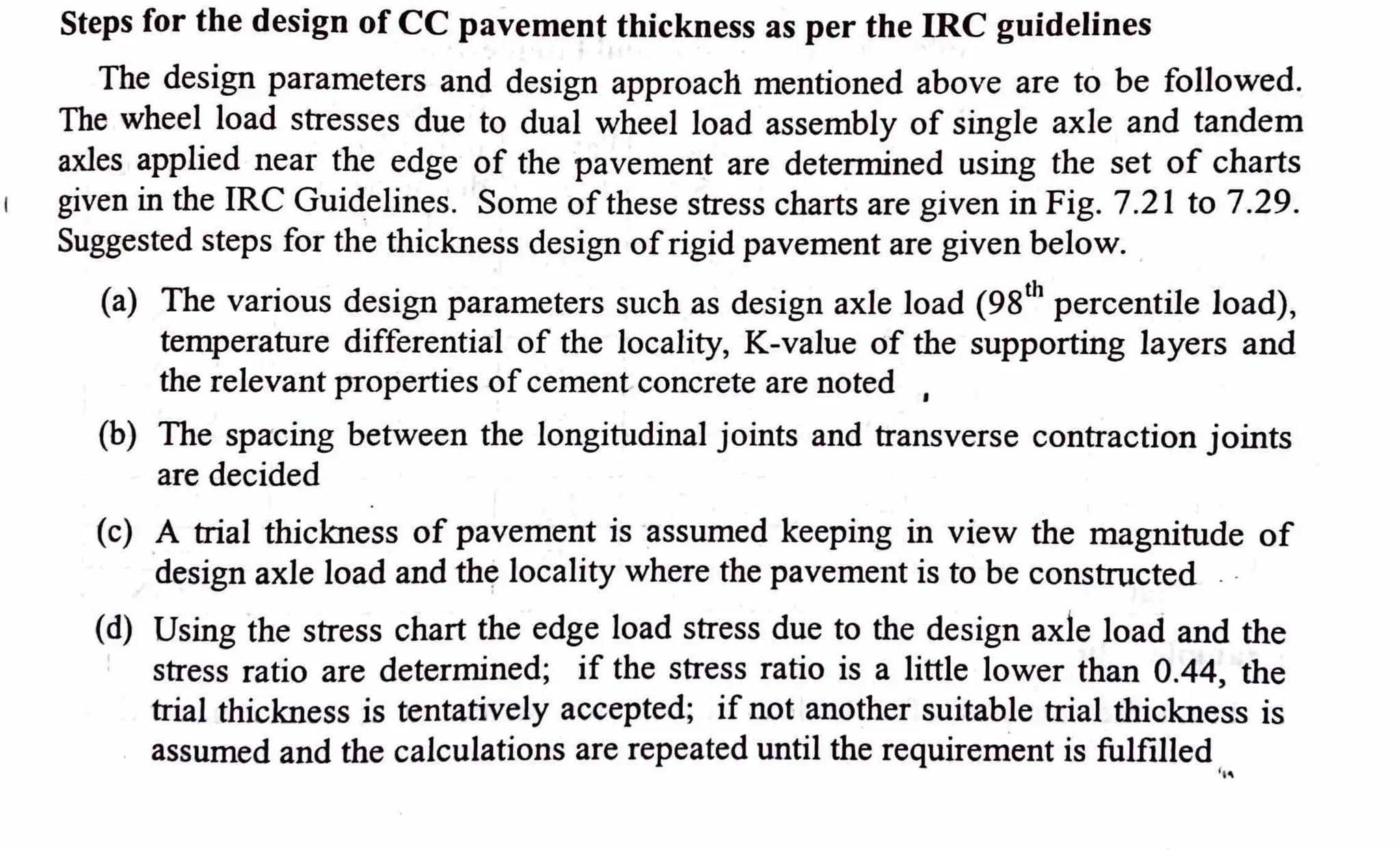

7.9.5 Design ofTie Bars at Longitudinal Joints

Objectives oftie bars

Tie bars are used across the longitudinal joints of cement concrete p_avements. Tie

bars are embedded at mid depth during concreting ensure th~ two adJacent sl~bs on

either side of the longitudinal joint to remain firmly to~et~er a~d to_prev~nt opem~g up

oftheJ·o· t S F. 7 17 and 7.32. The ]ongitudinalJomts with tie bars act as lunges

m . ee ig. . Tl . b t

and help to relieve part of warping stresses in CC pavement. 1e tie ars are no

designed to act as load tran~_fer devices.](https://image.slidesharecdn.com/pd-m4-rpdesign-240619105915-3505d4f1/85/Pavement-Design-Rigid-Pavement-Design-pdf-9-320.jpg)