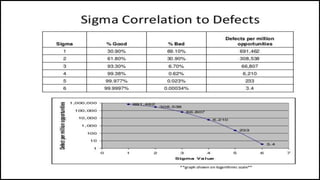

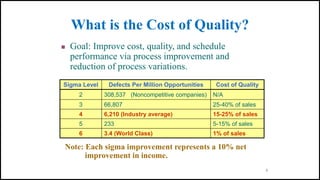

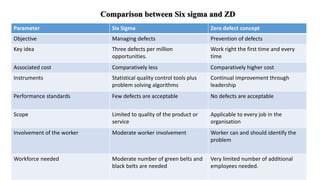

Six Sigma is a methodology for process improvement aimed at reducing defects. The key objectives are improved processes, product performance, and reliability. The goal is to reduce defects to near zero by decreasing process variations. Higher sigma levels correlate with fewer defects per million opportunities and lower costs of poor quality. Zero Defect programs take the approach of preventing defects entirely by designing processes to eliminate defects. OHSAS 18001 provides an occupational health and safety management system framework to help organizations identify and control risks, reduce accidents, aid compliance, and improve performance through establishing safe work procedures.