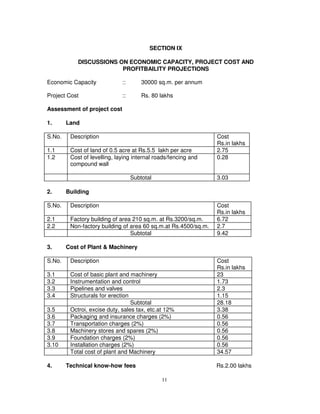

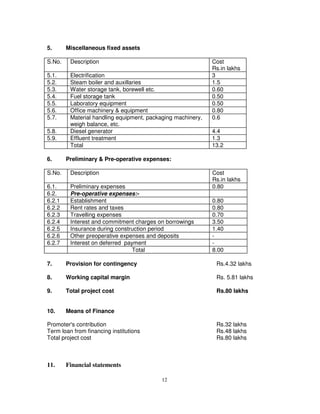

The document discusses particle board, including its characteristics, manufacturing process, applications, demand and manufacturers in India. It provides details on raw material requirements, project costs, profitability projections and a SWOT analysis. In summary, the document analyzes the particle board industry in India, outlines the manufacturing process, and evaluates the economic viability of starting a new particle board production facility.