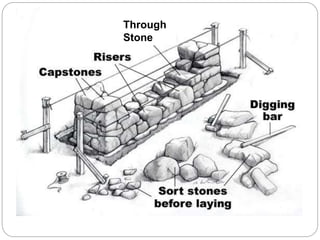

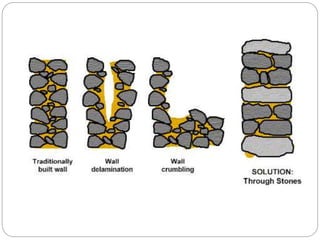

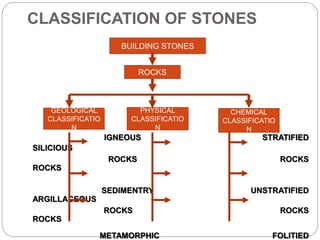

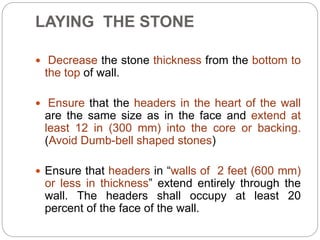

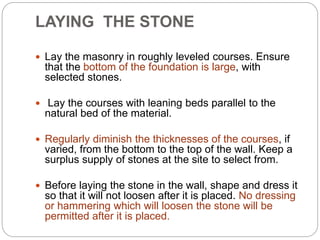

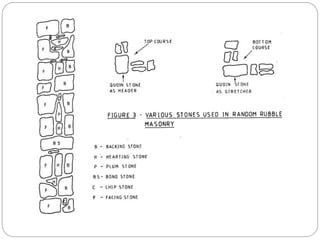

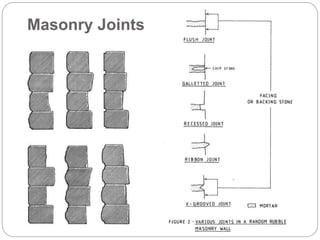

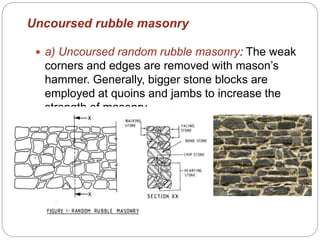

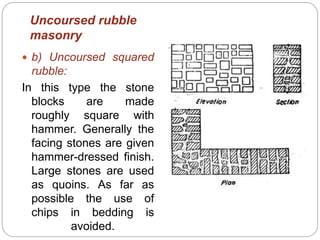

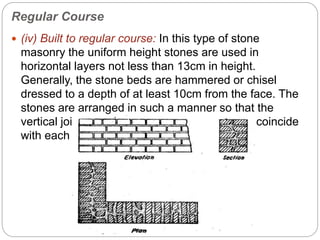

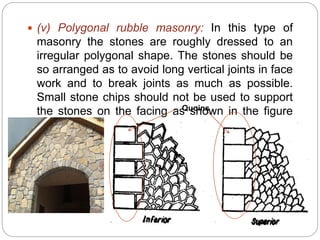

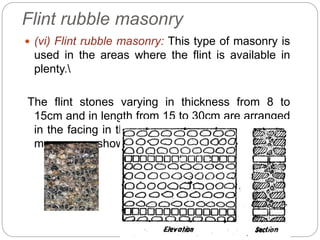

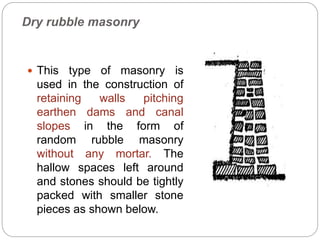

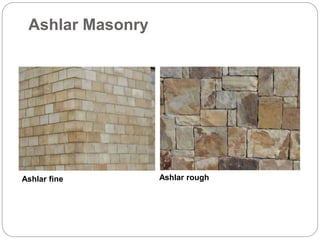

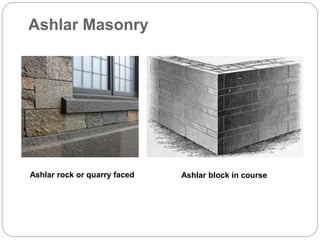

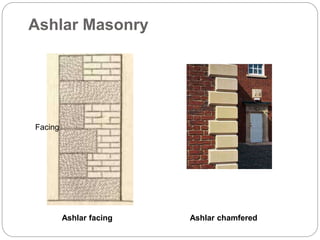

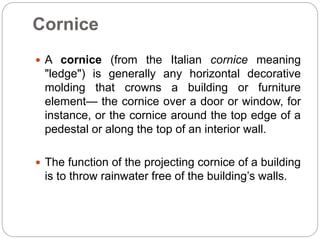

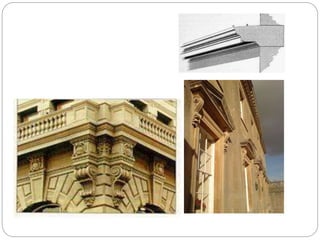

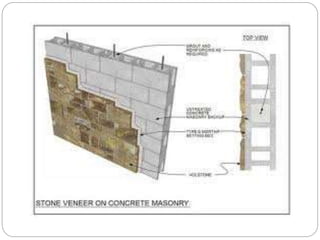

This document provides information about stone masonry. It was prepared by civil engineering students for their class. The document defines stone masonry and discusses the various uses of stone in construction. It describes how to select and lay stone, including decreasing thickness from bottom to top and ensuring headers extend through the wall. The document also classifies stones and discusses the characteristics of good building stones, such as appearance, structure, hardness and durability. It describes different types of stone masonry like rubble and ashlar masonry.