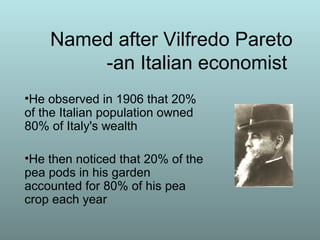

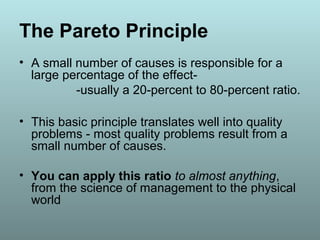

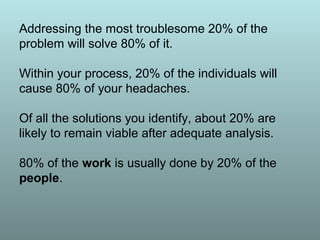

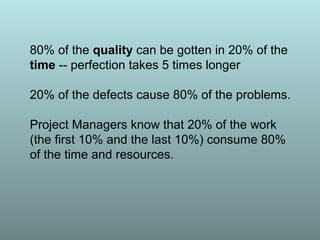

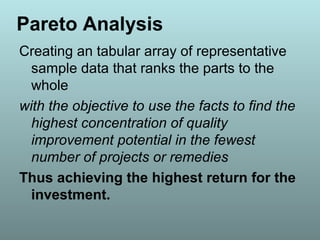

The Pareto Principle, or 80:20 rule, suggests that a small number of causes (20%) are responsible for the majority of effects (80%), as illustrated by Vilfredo Pareto's observations on wealth distribution and crop yields. This principle applies across various fields, including quality management, emphasizing that by addressing the vital few issues, one can achieve significant improvements. Using tools like Pareto charts, organizations can prioritize actions to tackle the most impactful problems and maximize resource allocation for quality enhancement.

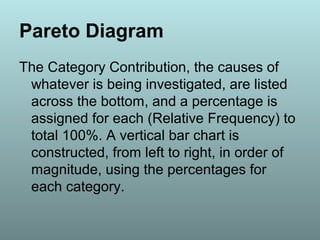

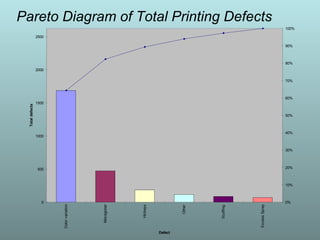

![Relative Frequency

[(Category Contribution) / (Total of all

Categories)] x 100 expressed in bar chart

form.](https://image.slidesharecdn.com/kamleshwar-pareto-140408014925-phpapp02/85/Pareto-chart-importance-making-16-320.jpg)

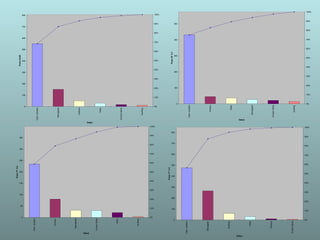

![Cumulative Frequency

[(Relative Frequency of Category

Contribution) + (Previous Cumulative

Frequency)] expressed as a line graph](https://image.slidesharecdn.com/kamleshwar-pareto-140408014925-phpapp02/85/Pareto-chart-importance-making-17-320.jpg)