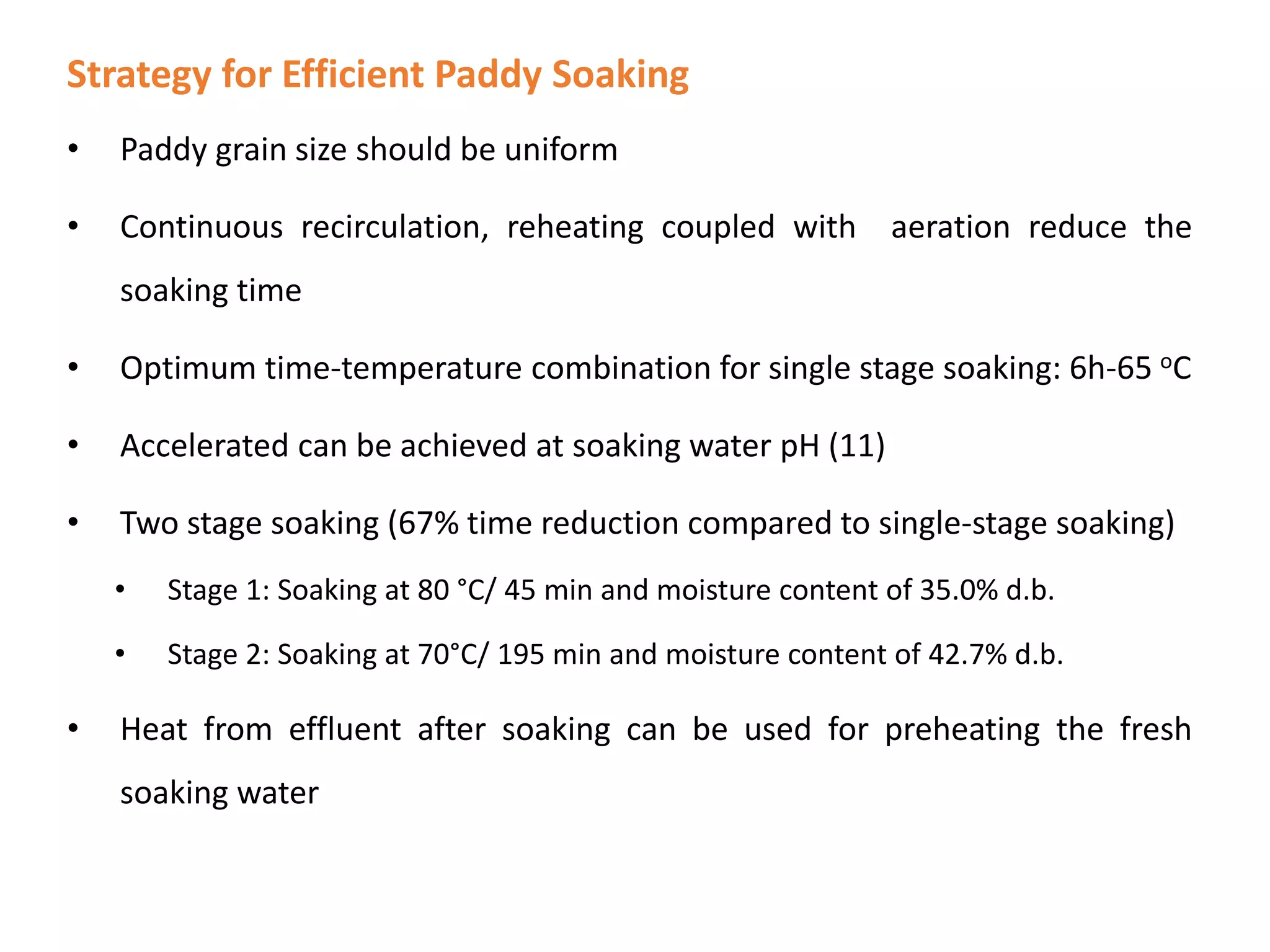

The document discusses the process of parboiling paddy rice. It involves pre-steaming the paddy to soften it, soaking it in hot water to allow absorption of water and nutrients, post-steaming to gelatinize the starch, drying and then tempering. Parboiling increases rice recovery and nutrient content while reducing breakage. Key factors that influence quality are soaking time/temperature, steaming parameters and drying time/temperature. The document recommends strategies like two-stage soaking and double-pass drying with tempering to improve efficiency and quality of parboiled rice.