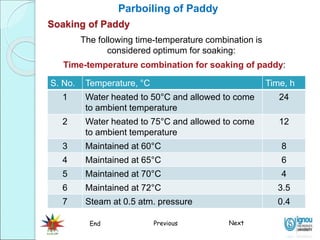

The document discusses the process of parboiling paddy to produce parboiled rice. Parboiling involves soaking, steaming, and drying the paddy. Soaking is typically done at elevated temperatures from 60-72°C for 3.5-24 hours depending on the temperature. Steaming is then done using saturated steam at 1-5 kg/cm2 for 2-30 minutes. The paddy is then dried in multiple passes until the moisture content is reduced to 14-16%. Parboiling increases head rice recovery, nutrition, and reduces losses during cooking compared to raw rice.