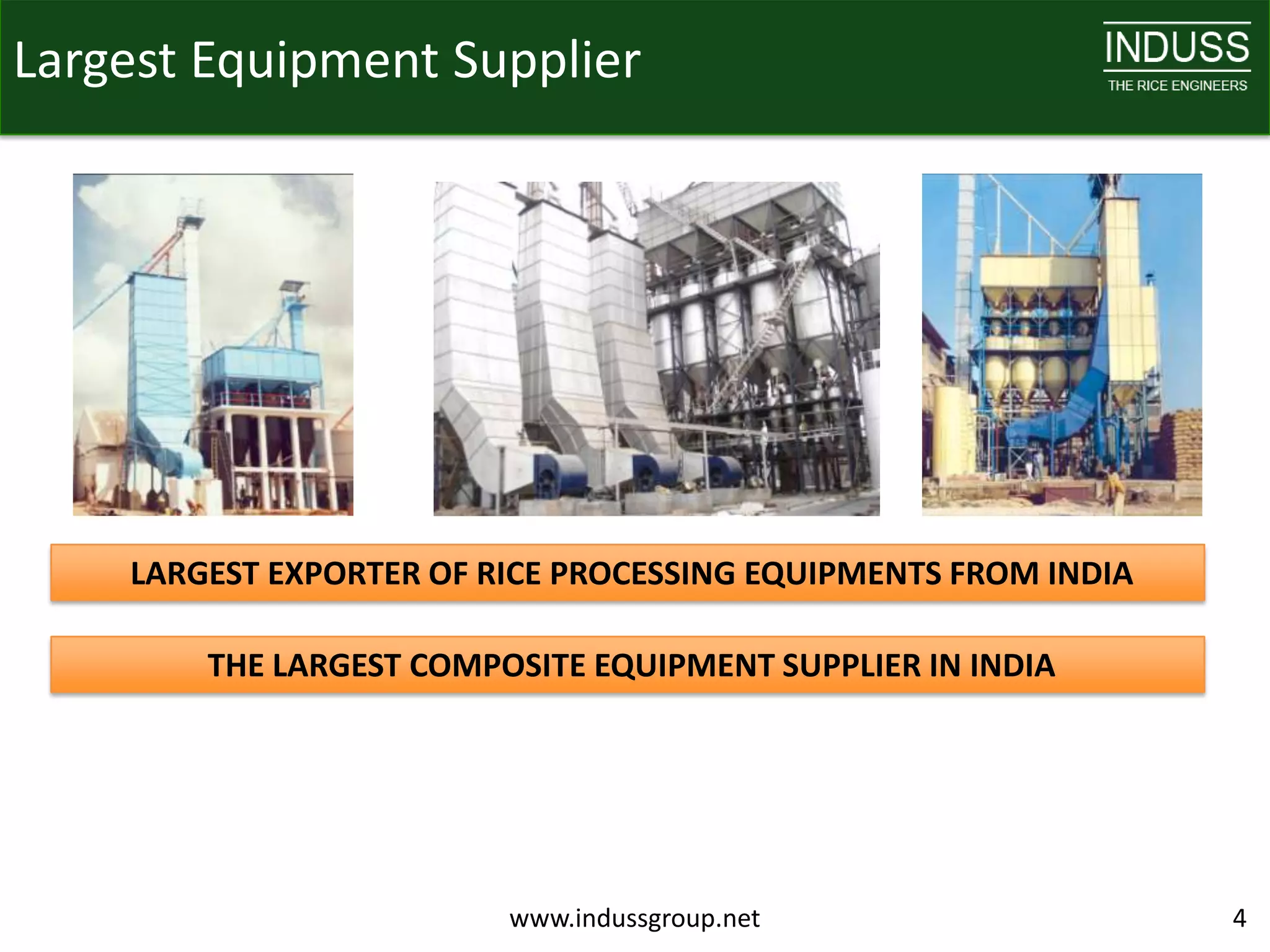

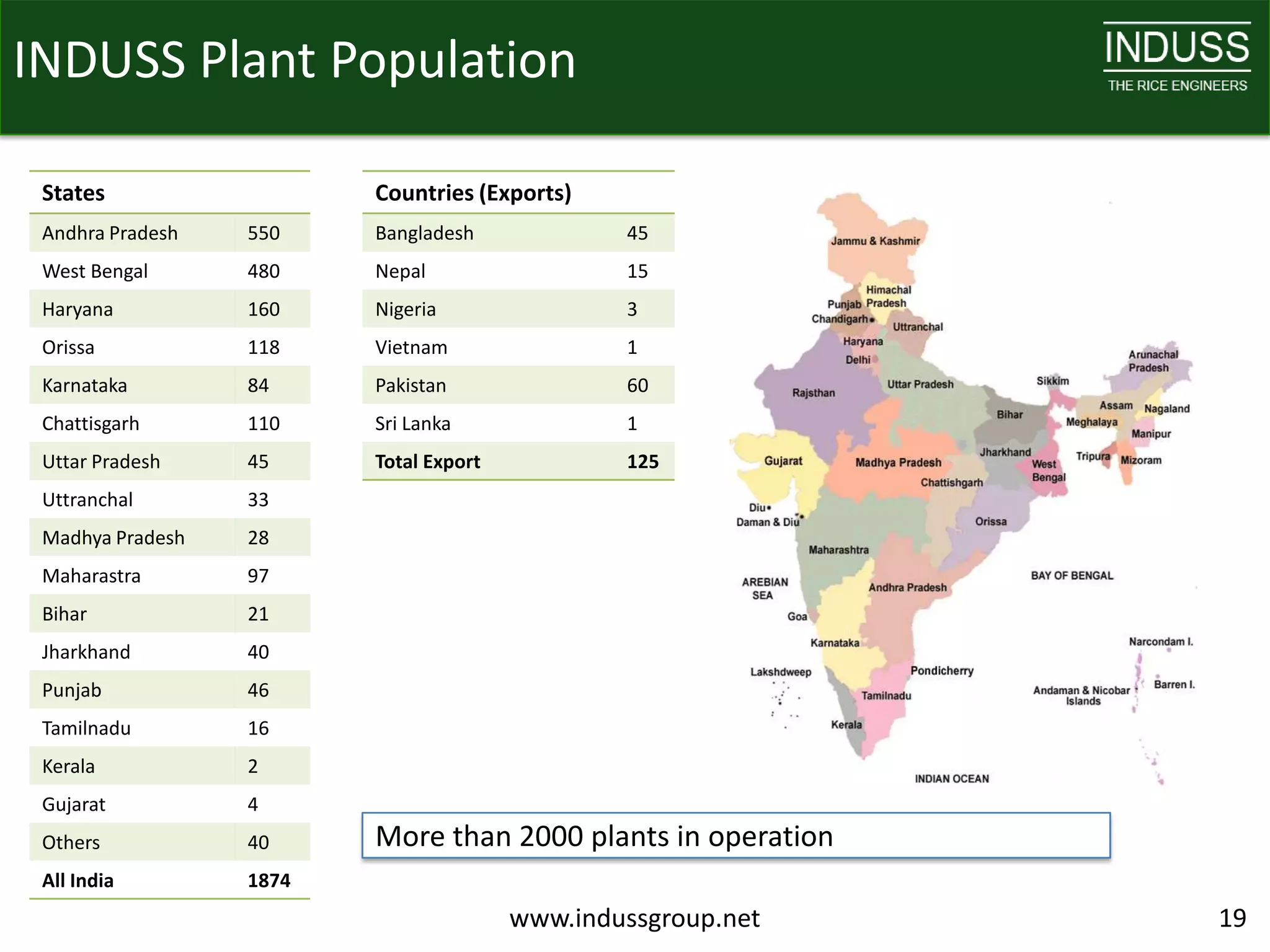

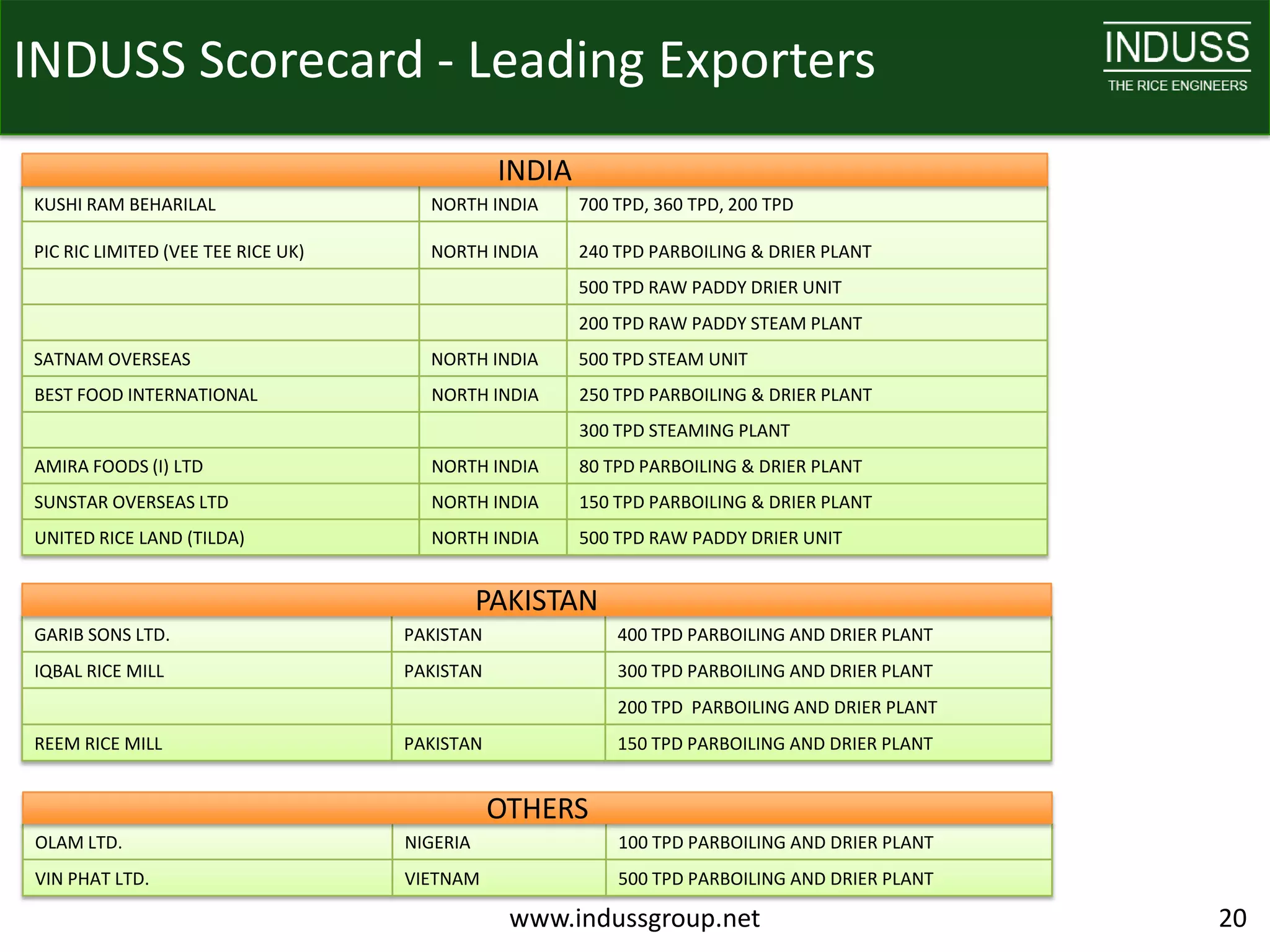

S.S. Aggarwal has over 30 years of experience in parboiling technology. It operates plants across India and exports equipment to over 20 countries. It pioneered continuous parboiling processes and has the largest market share as the largest supplier of rice processing equipment from India. It has ongoing research partnerships and has commissioned over 2000 plants worldwide.