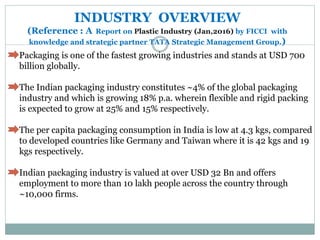

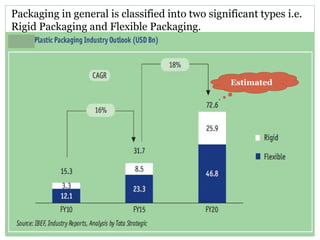

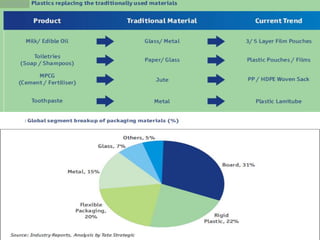

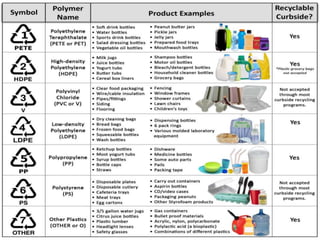

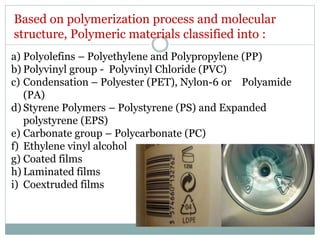

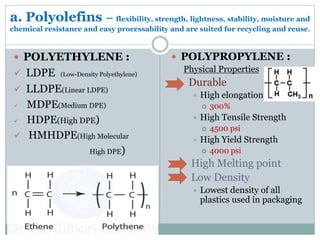

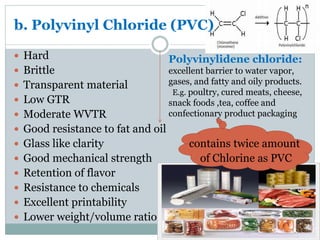

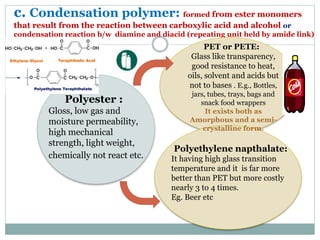

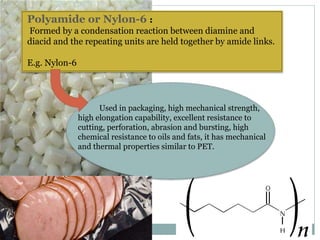

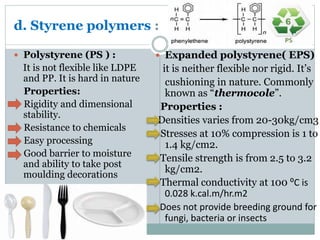

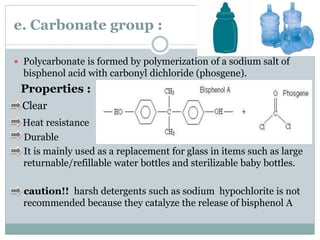

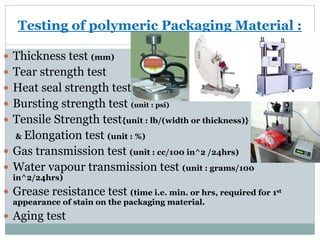

This document provides an overview of polymeric food packaging materials. It discusses the history and evolution of packaging from skins and leaves to modern materials. The key types of polymeric materials used in food packaging are described, including polyolefins, polyvinyl chloride, polyesters, nylons, polystyrene, and polycarbonate. Properties, applications, and testing methods of these materials are summarized. The packaging industry is growing significantly with increasing global demand and consumption.