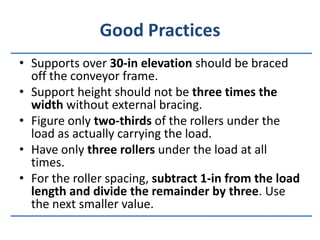

This document discusses various types of conveyors used to transport packages and materials, including their design and recommended usage. It covers gravity conveyors, skatewheel conveyors, roller conveyors, belt conveyors, screw conveyors, bucket conveyors, and pneumatic conveyors. For each type, it provides details on components, capacity, speed, inclination limits, and other specifications. The document concludes with rules of thumb for selecting and sizing different conveyor types based on the material and throughput requirements.