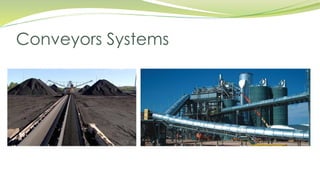

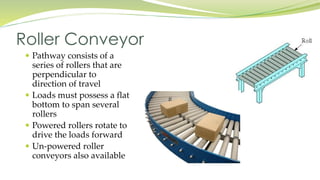

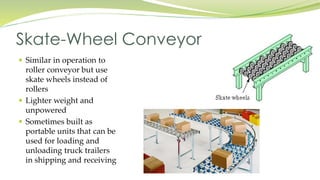

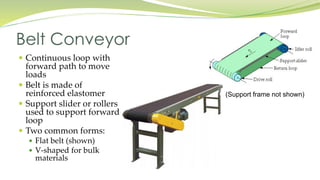

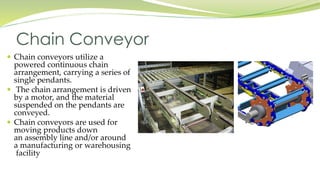

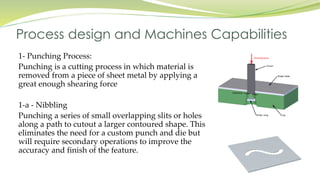

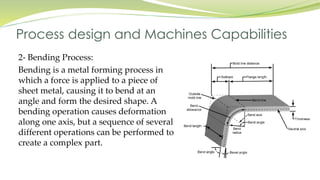

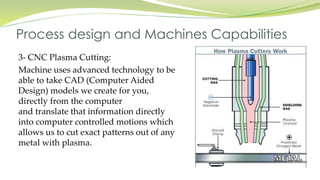

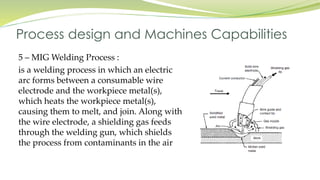

This document discusses conveyor systems and powered turntable conveyors. It describes several types of conveyors including roller, belt, chain, and overhead conveyors. It then provides details on a powered turntable conveyor case study, including its bill of materials, specifications, and applications in video examples. The document concludes by describing several machine capabilities for production processes including punching, bending, plasma cutting, sawing, welding, turning, and milling that could be used with conveyor systems.