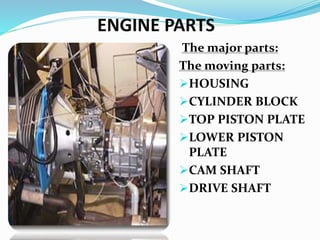

The document describes a new type of internal combustion engine called the OX2 engine. It has only six major components, with three moving parts. It works by using two piston plates and eight cylinders arranged in a circle to convert the reciprocating motion of the pistons into rotational motion. Testing shows the new design improves efficiency, torque, and horsepower over previous iterations. The OX2 engine promises to be more efficient, powerful, and eco-friendly than traditional engines.