Embed presentation

Downloaded 67 times

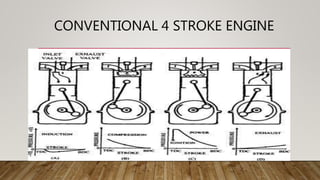

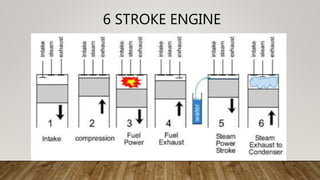

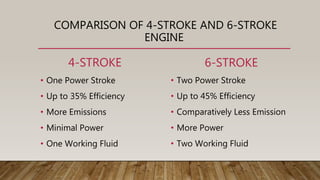

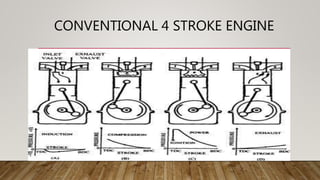

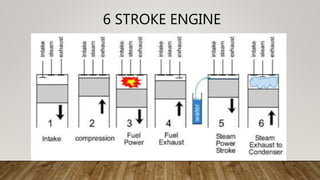

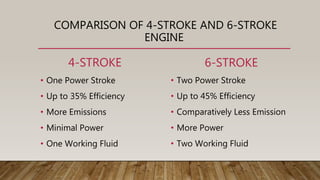

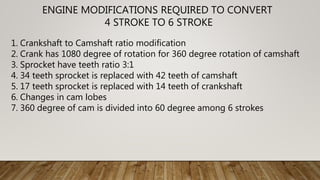

This document discusses 6-stroke engines and compares them to conventional 4-stroke engines. It outlines different types of 6-stroke engine designs, including single piston and opposed piston configurations. It then compares the key aspects of 4-stroke and 6-stroke engines such as efficiency, emissions, power output, and number of working fluids. The document also lists the modifications required to convert a standard 4-stroke engine to a 6-stroke design. Finally, it outlines the main advantages of 6-stroke engines, including reduced fuel consumption and pollution, less friction, higher efficiency, and more power from the additional power stroke.