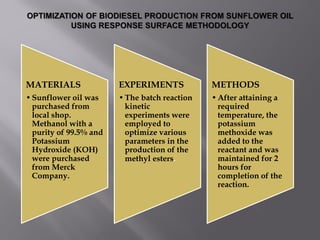

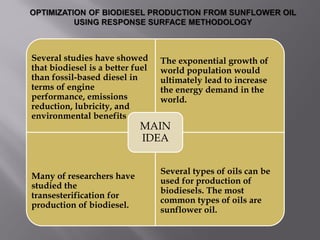

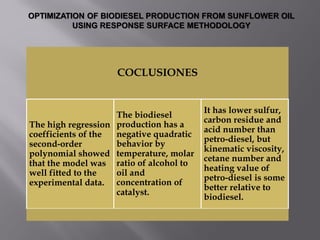

This document discusses the optimization of biodiesel production from sunflower oil using response surface methodology. Sunflower oil, methanol, and potassium hydroxide were used to produce methyl esters through a transesterification reaction. The effects of temperature, molar ratio of alcohol to oil, and catalyst concentration on biodiesel production were evaluated. A second-order polynomial model was fitted to the experimental data and showed that biodiesel production has a negative quadratic relationship with the parameters tested. The high regression coefficients indicated the model was a good fit for optimizing biodiesel production from sunflower oil.