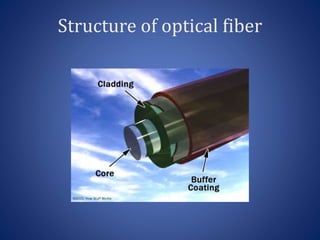

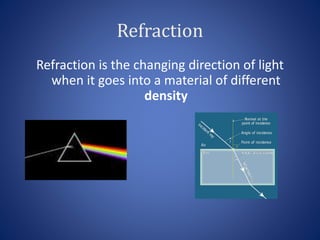

This document provides an overview of optical fibers, including their evolution, structure, working principles, classification, communication systems, advantages and applications. It discusses how optical fibers guide light using total internal reflection. Fibers are classified based on mode (single or multi-mode) and refractive index profile (step or graded). Key advantages are high bandwidth, low attenuation, immunity to EMI, and security. Applications include telecommunications, broadband, medicine, military and more. Optical fibers have become the backbone of long-distance networks since the 1980s due to refinements in manufacturing.