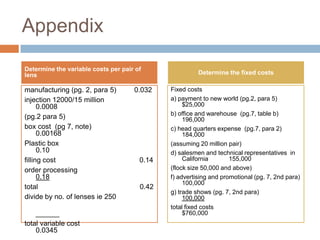

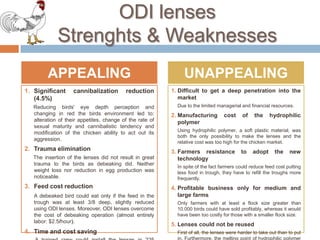

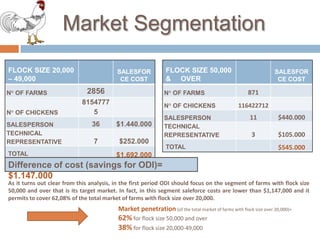

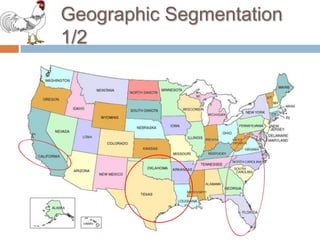

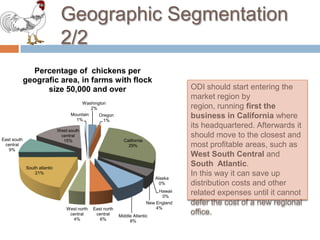

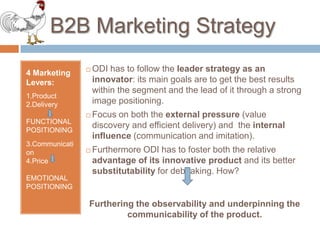

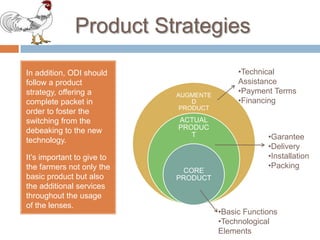

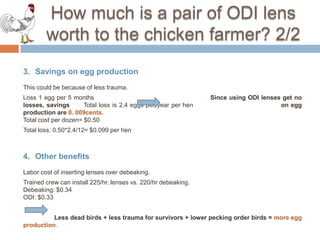

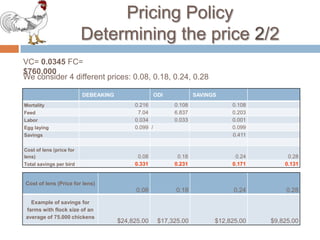

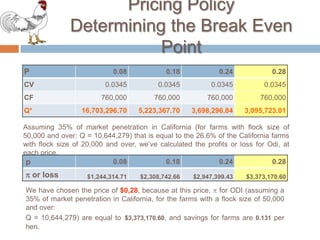

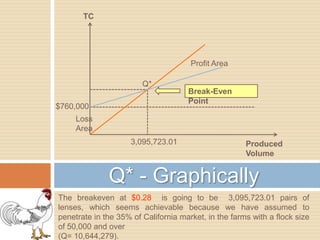

OpticalDistortion, Inc. developed contact lenses for chickens to partially blind them and reduce cannibalism on farms by 50%. The lenses have benefits like lower mortality and feed costs but also challenges like high manufacturing costs and farmer resistance to new technologies. ODI plans to target large chicken farms in California initially with a product bundle and pricing strategy of $0.28 per lens, pursuing market penetration through regional expansion.

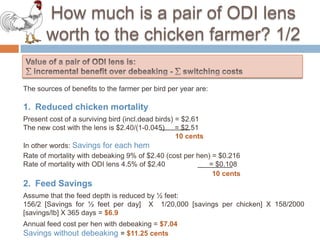

![TechnologicalElementsHow muchis a pair of ODI lensworthto the chickenfarmer? 1/2 Value of a pair of ODI lensis: incremental benefit overdebeaking - switchingcostsThe sources of benefitsto the farmer per bird per year are:ReducedchickenmortalityPresentcost of a survivingbird (incl.deadbirds) = $2.61 The newcostwith the lensis $2.40/(1-0.045) = $2.51 10 centsIn otherwords: Savingsforeach hemRate of mortalitywithdebeaking 9% of $2.40 (cost per hen) = $0.216Rate of mortalitywith ODI lens 4.5% of $2.40 = $0.108 10 centsFeed Savings Assume that the feed depth is reduced by ½ feet:156/2 [Savings for ½ feet per day] X 1/20,000 [savings per chicken] X 158/2000 [savings/lb] X 365 days =$6.9 Annual feed cost per hen with debeaking = $7.04 Savings without debeaking= $11.25 cents](https://image.slidesharecdn.com/opticaldistortioninc-100608103509-phpapp01/85/Optical-distortion-inc-16-320.jpg)