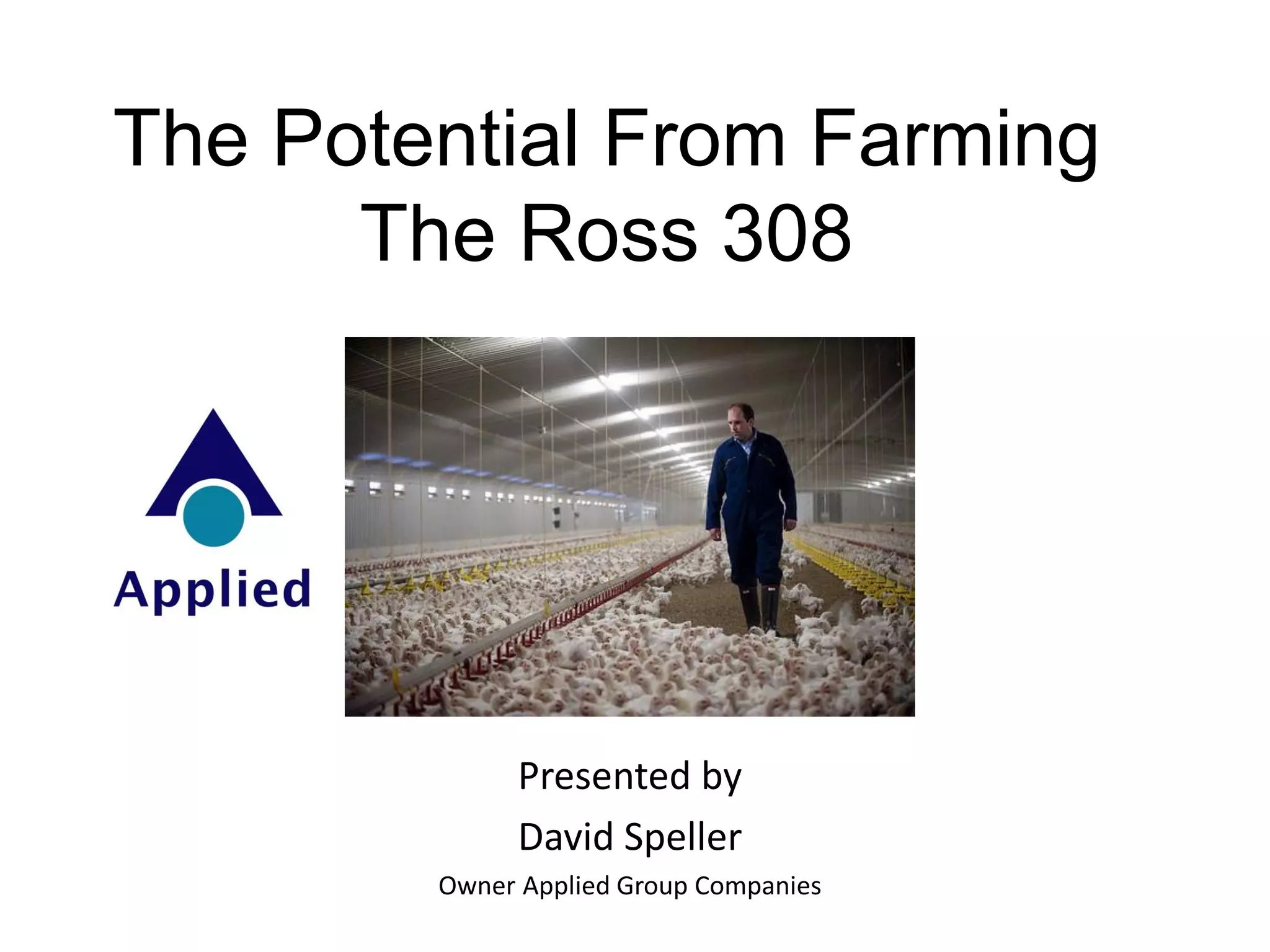

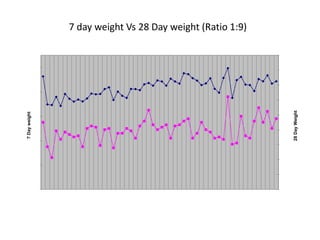

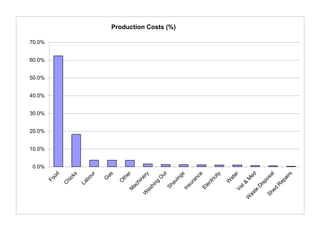

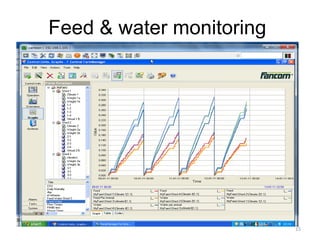

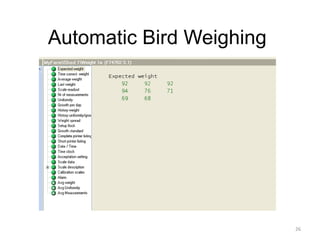

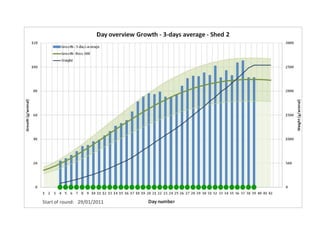

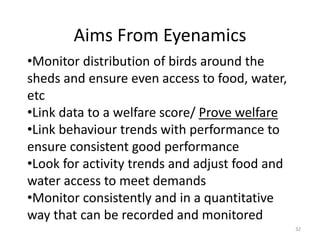

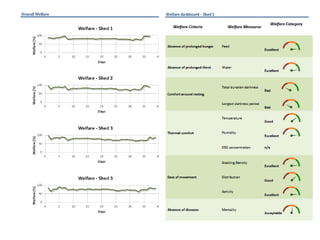

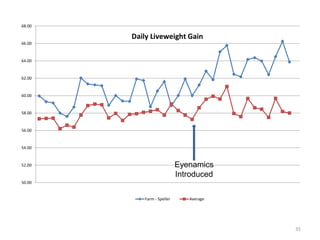

David Speller owns several poultry farming operations that raise Ross 308 broiler chickens for customers. He discusses expanding operations to a total of 2.25 million birds per year across multiple farms. Key factors for success include efficiency, optimal welfare standards, good customer relations, appropriate scale, and sound investment. Data from monitoring systems like eyenamic cameras and automatic weighing help ensure bird welfare and peak performance, with average daily live weight gain increasing after introducing eyenamic monitoring. Proper facilities, feed management, and cleaning/disinfection are also essential to reach the genetic potential of the high-performing Ross 308 birds.