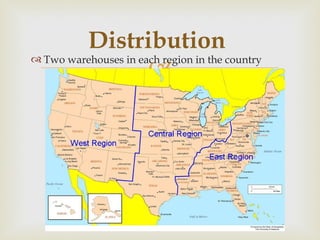

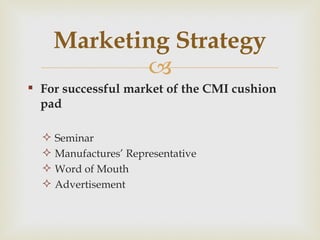

1. The document discusses a marketing strategy for a new cushion pad product called the CMI cushion pad that has the potential to double the company's revenue.

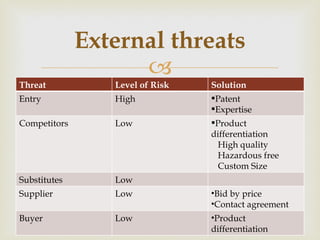

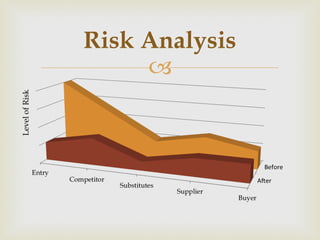

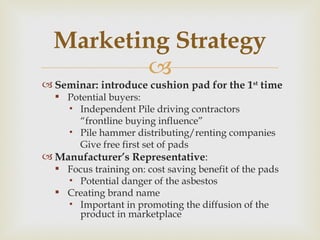

2. It analyzes risks from competitors, substitutes and suppliers as low, and provides a marketing strategy focusing on seminars, manufacturers' representatives, and word of mouth advertising.

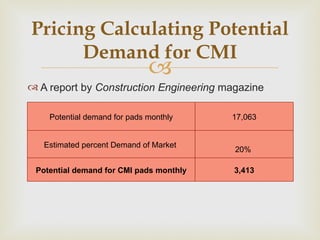

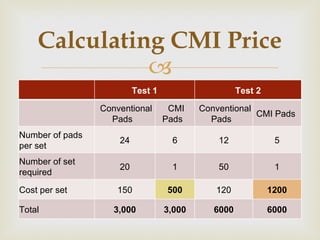

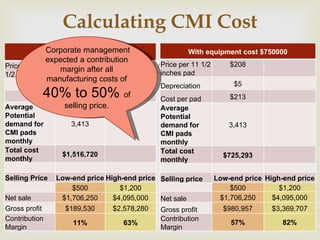

3. Financial projections estimate that capturing 20% of the market with a price of $500-$1200 per pad could generate over $1.7 million to $4 million in additional monthly net sales.

![Marketing Strategy Word of mouth Pile hammer manufacturers To influence recommendations Professor Stephen McCormack Department to study pile driving and was a respected authority Advertisement [Magazine/Newspaper/TV ads] Publish our test results in magazine & Newspaper Engineering channel on TV](https://image.slidesharecdn.com/cmi1-1330102525398-phpapp02-120224105840-phpapp02/85/Consulting-Case-Study-Senior-Class-7-320.jpg)