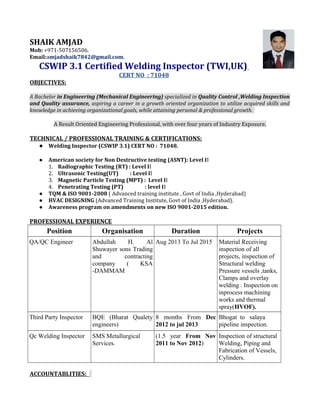

Shaik Amjad is a mechanical engineer seeking a quality control role. He has over 4 years of experience in roles inspecting welding, materials, coatings and more. He holds certification in welding inspection from TWI as well as Level II certification in various NDT methods from ASNT. His experience includes projects in pipeline and pressure vessel fabrication for clients in Saudi Arabia and India. He is knowledgeable in various codes including ASME, API, and Saudi specifications.