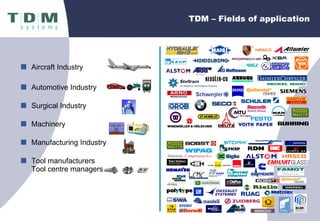

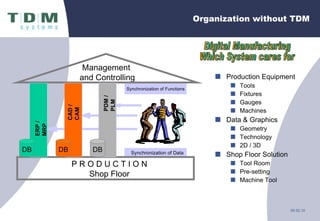

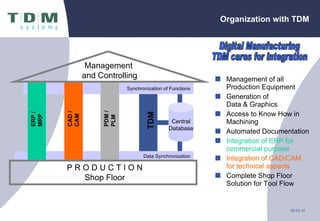

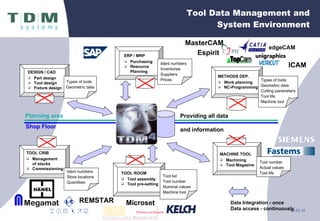

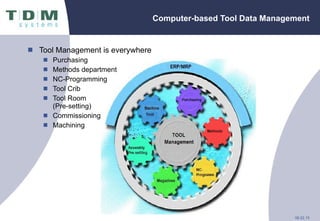

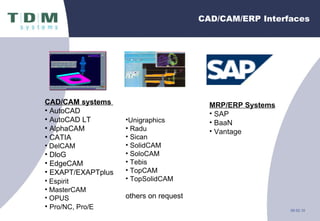

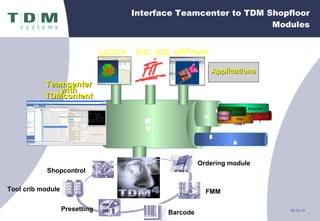

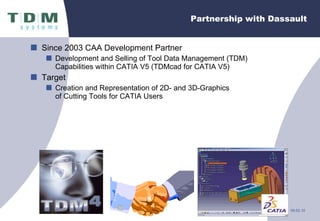

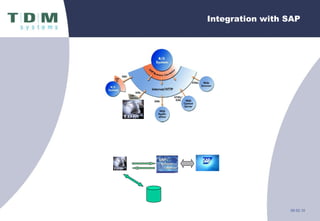

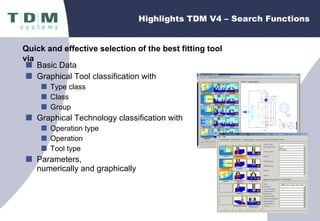

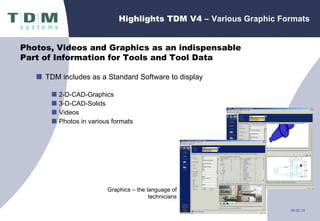

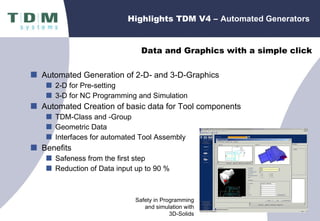

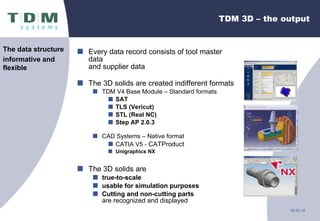

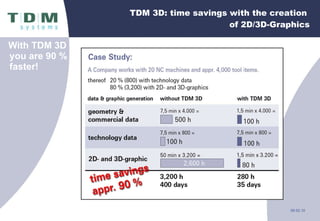

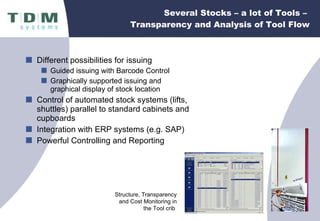

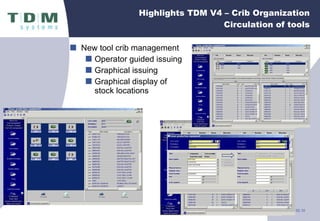

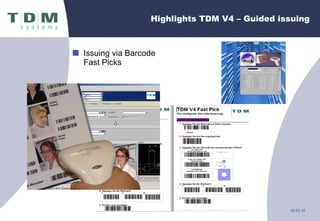

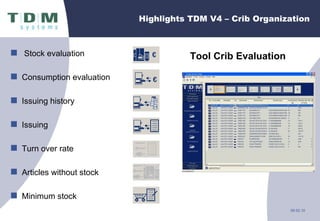

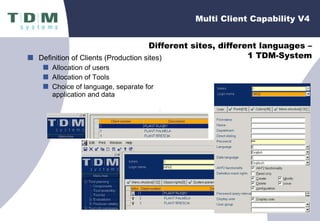

TDM Systems is a leading provider of tool data management (TDM) software and services. It was founded in 1993 in Tübingen, Germany and now has over 900 customers worldwide. The company's flagship TDM V4 software allows customers to manage tool data, generate 2D and 3D graphics, integrate with CAD/CAM and ERP systems, and track tool inventory and usage. TDM Systems aims to increase productivity for customers in industries such as aerospace, automotive, and machinery manufacturing.