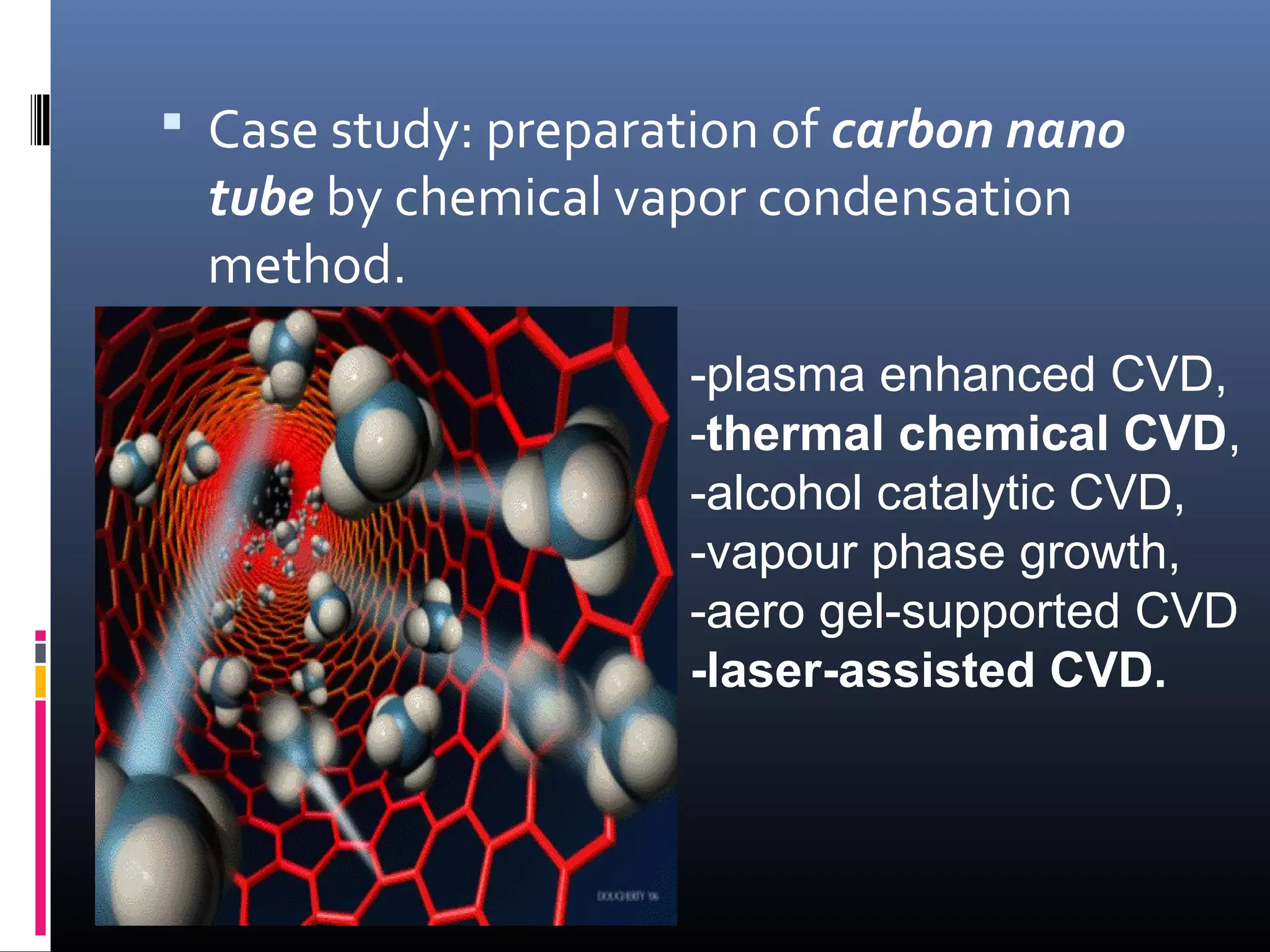

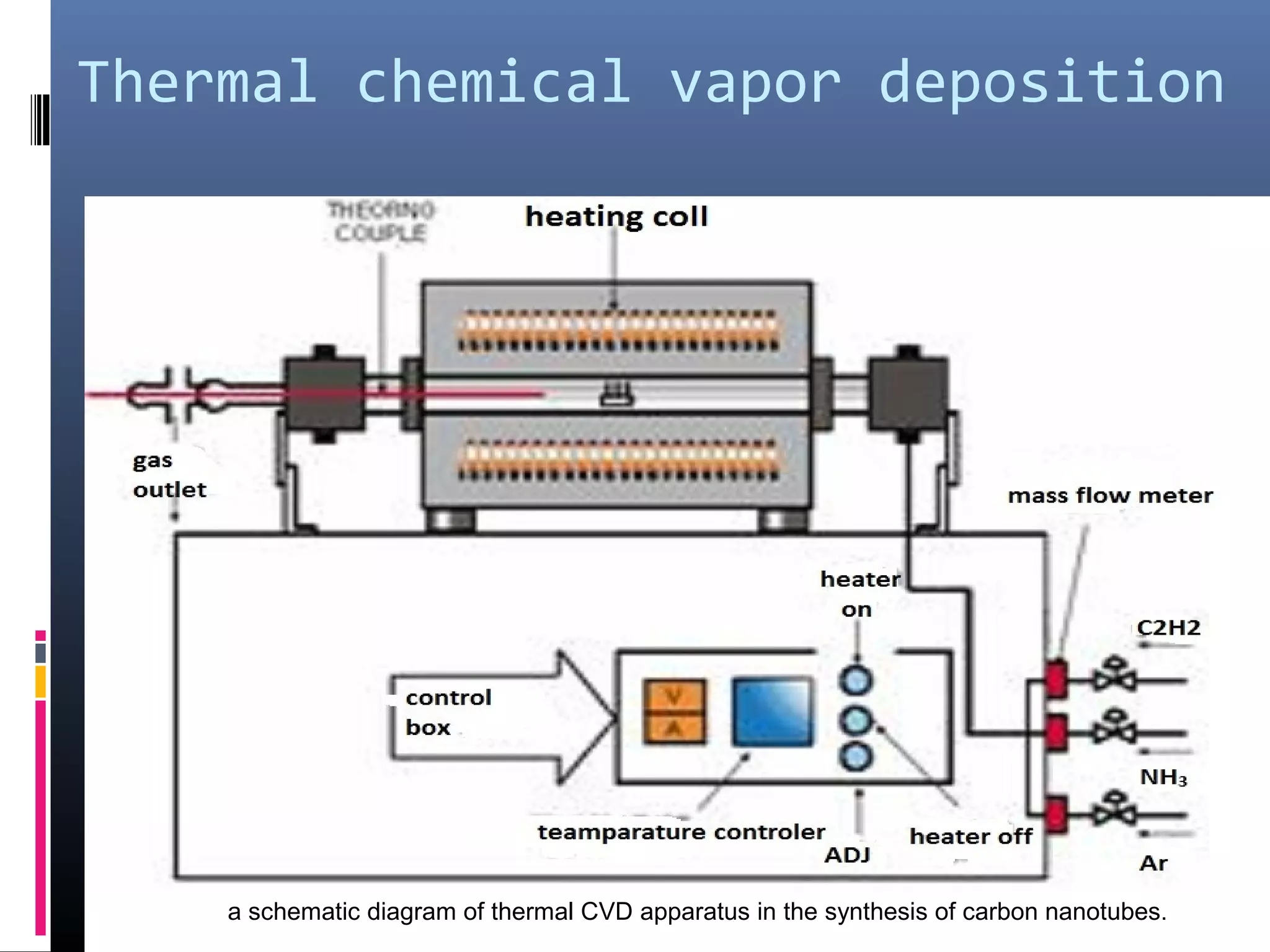

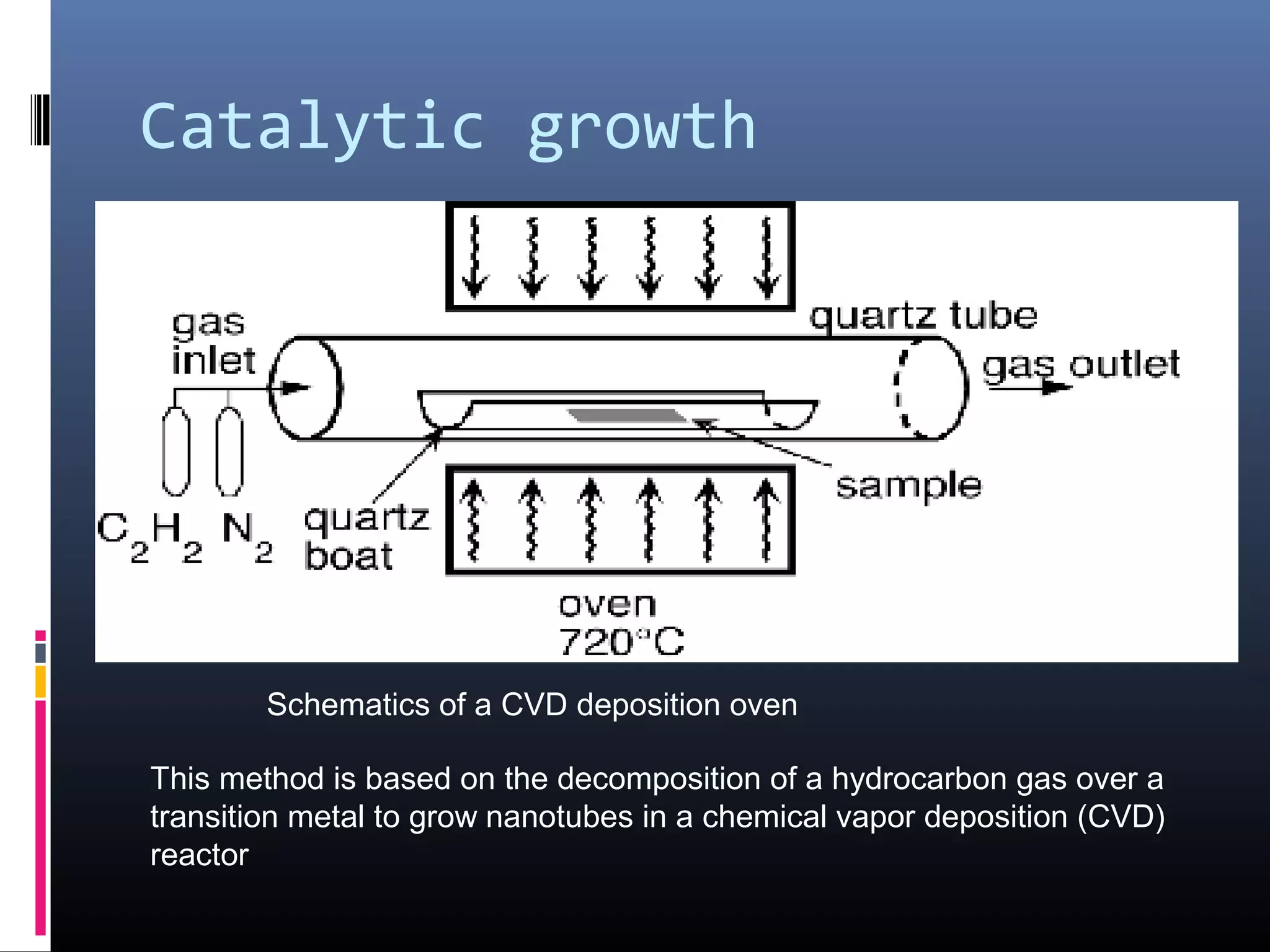

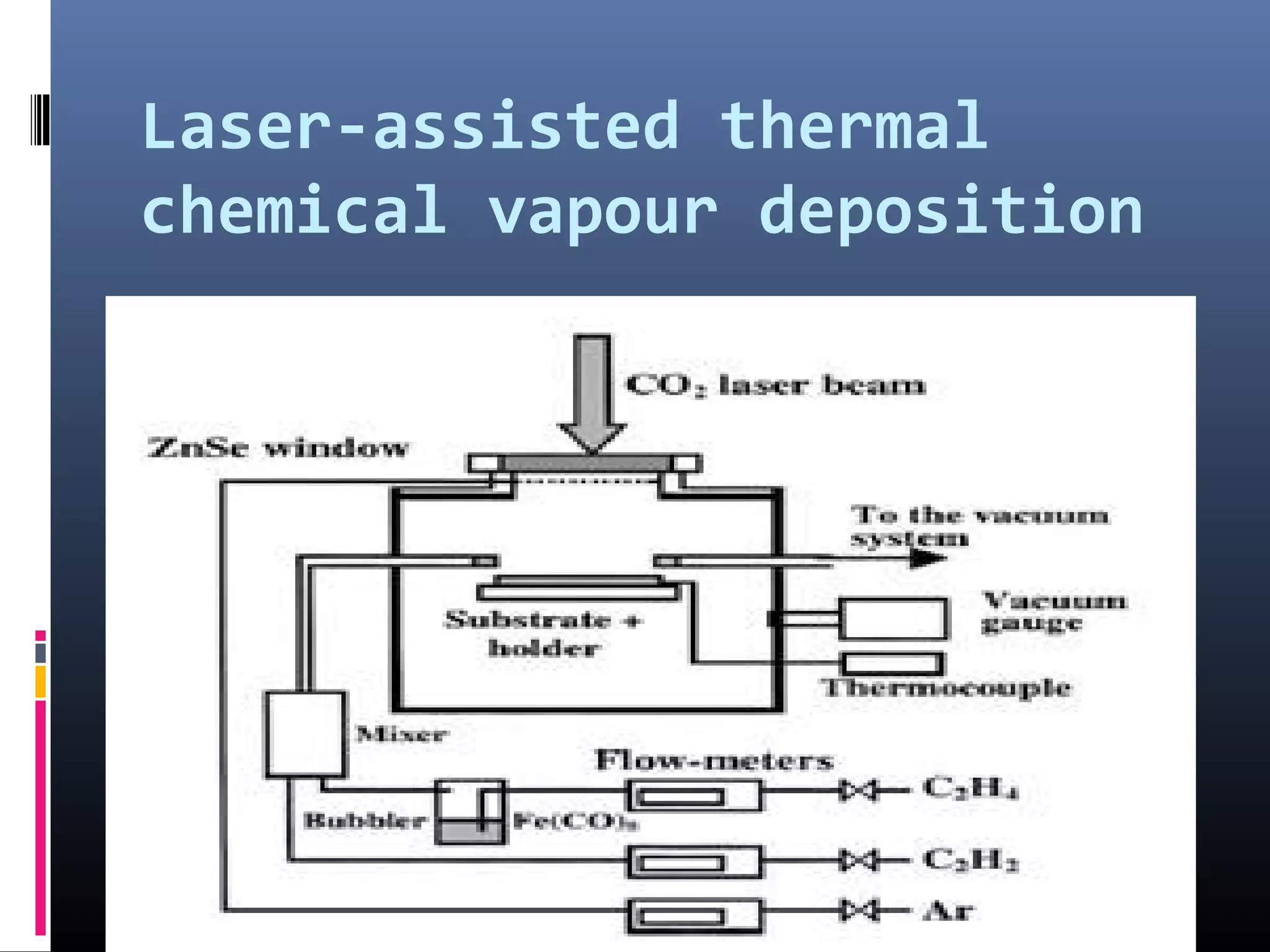

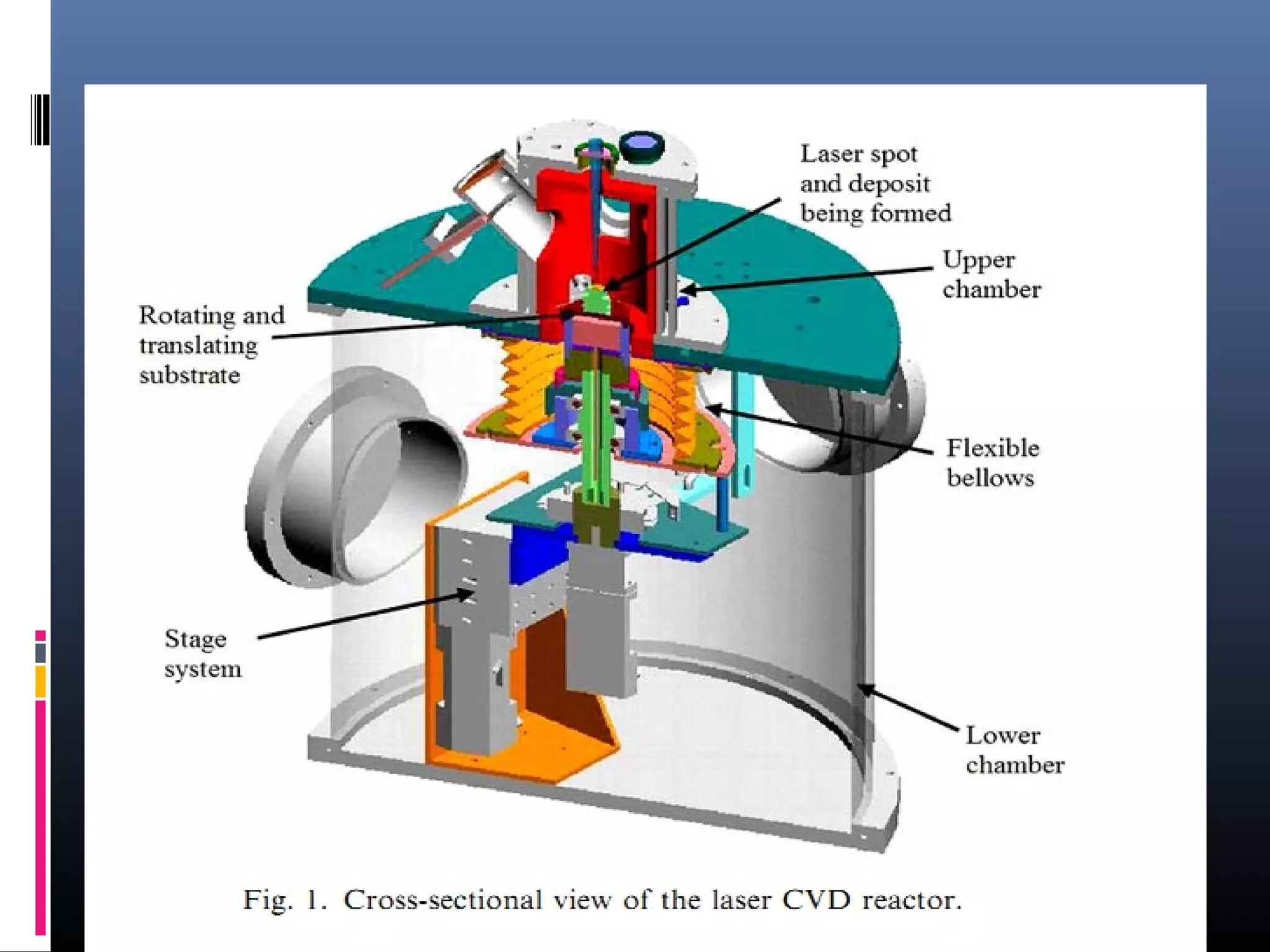

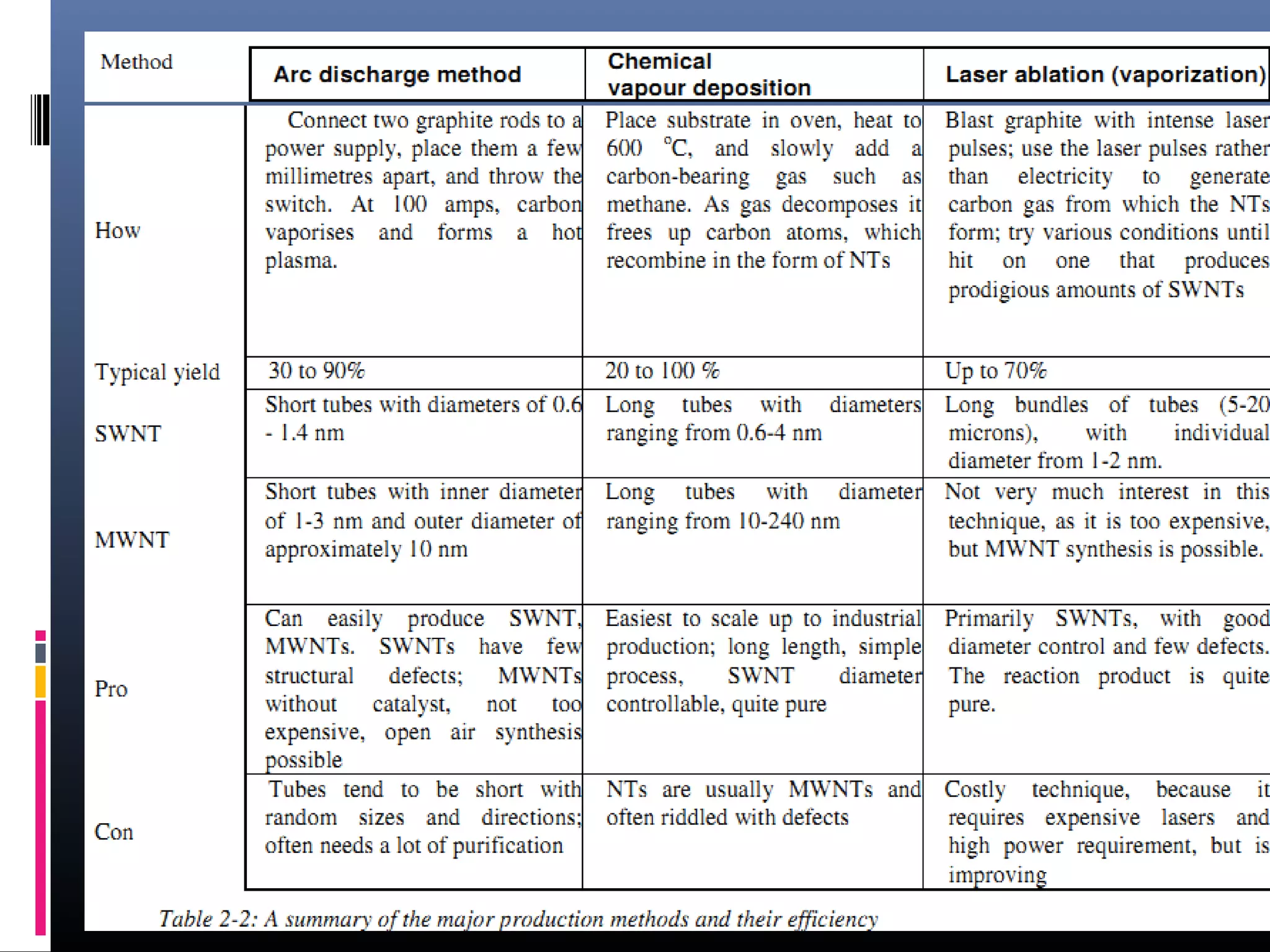

This document discusses carbon nanotube synthesis using chemical vapor deposition (CVD) methods. It describes thermal CVD and laser-assisted thermal CVD processes. For thermal CVD, a hydrocarbon gas is decomposed over a transition metal catalyst at temperatures of 450-1050°C to grow multi-walled nanotubes with diameters from 10-240nm or single-walled nanotubes with diameters from 0.6-4nm. For laser-assisted CVD, a CO2 laser pyrolyzes iron pentacarbonyl and ethylene or acetylene vapors to produce single-walled nanotubes with diameters from 0.7-2.5nm and multi-walled nanotubes with