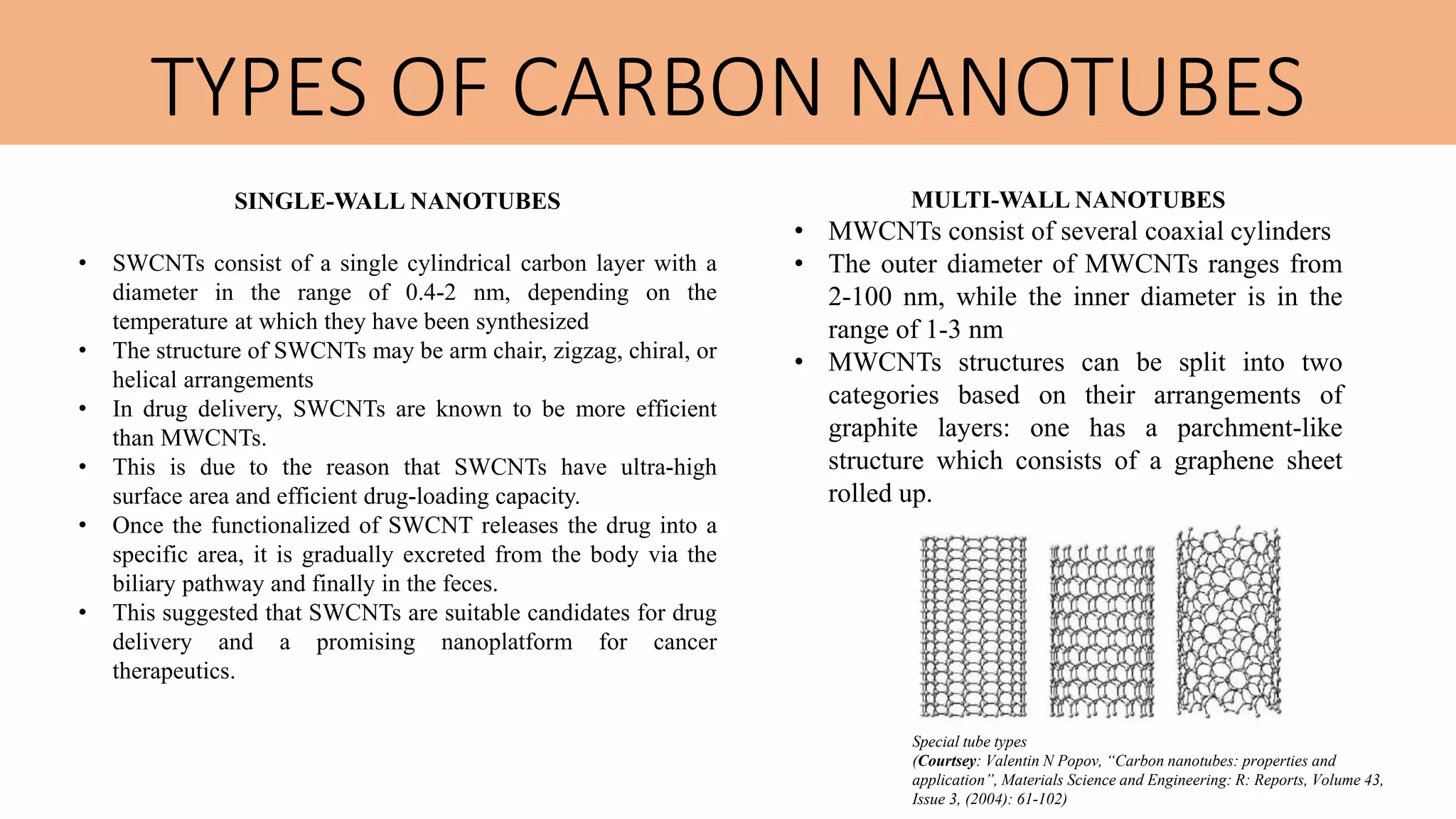

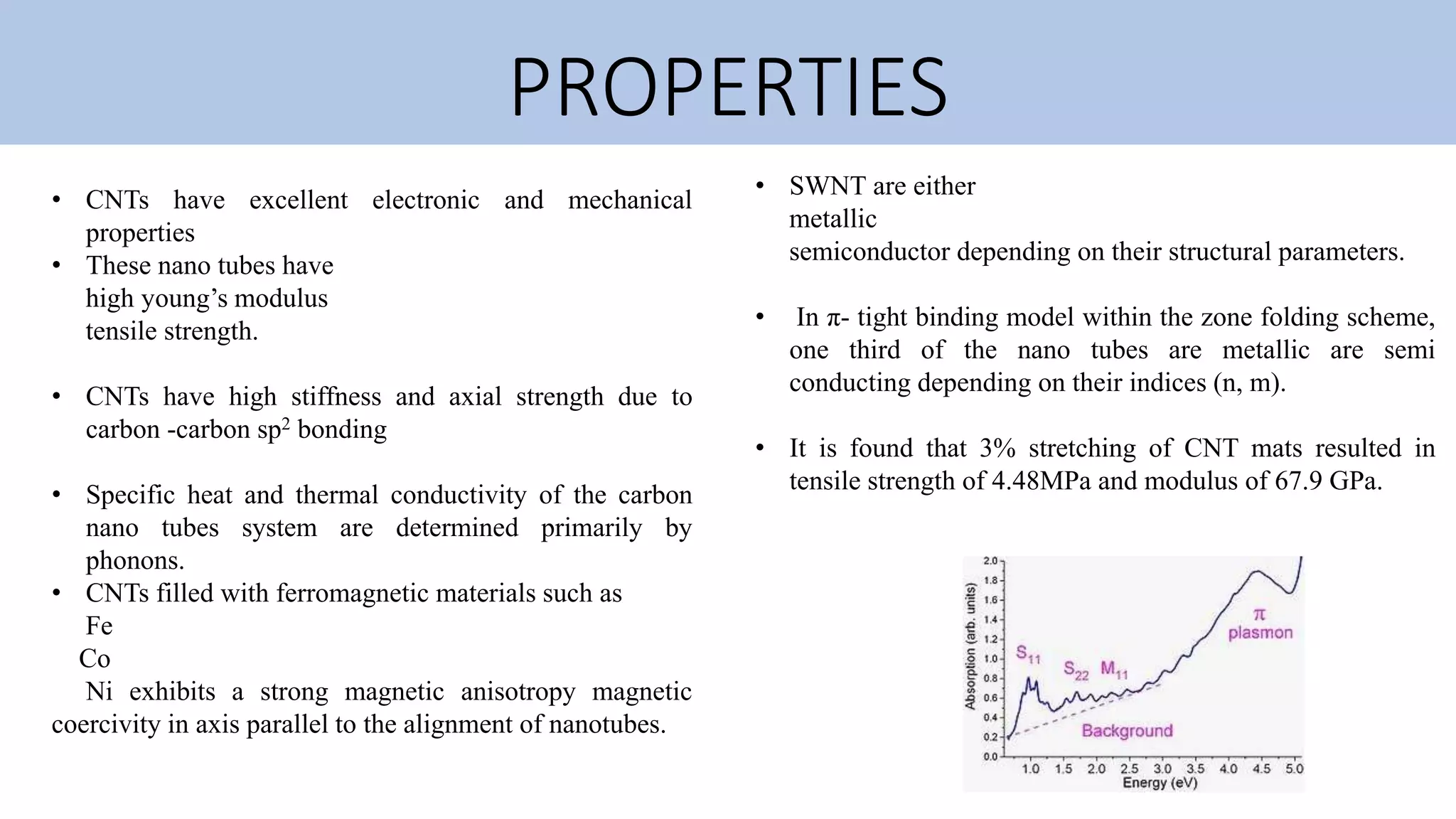

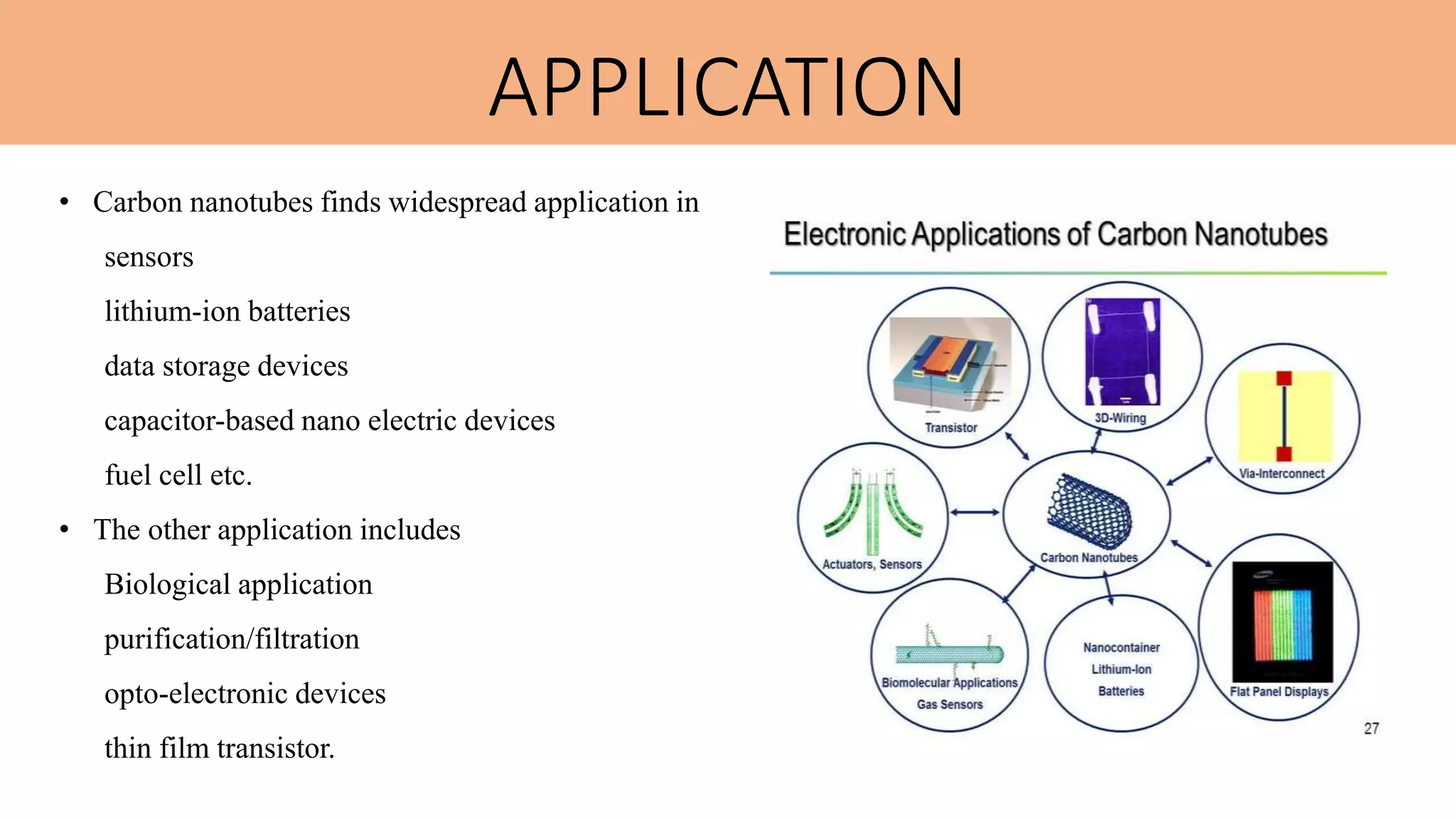

The seminar presentation discusses the properties, synthesis, characterization, and applications of carbon nanotubes (CNTs). It highlights their types, including single-wall and multi-wall nanotubes, and various techniques for their synthesis, such as electric arc discharge, laser ablation, and chemical vapor deposition. Additionally, it covers purification methods, the distinct structural features of CNTs, and their promising applications in fields like medicine, energy, and electronics.

![REFERENCES

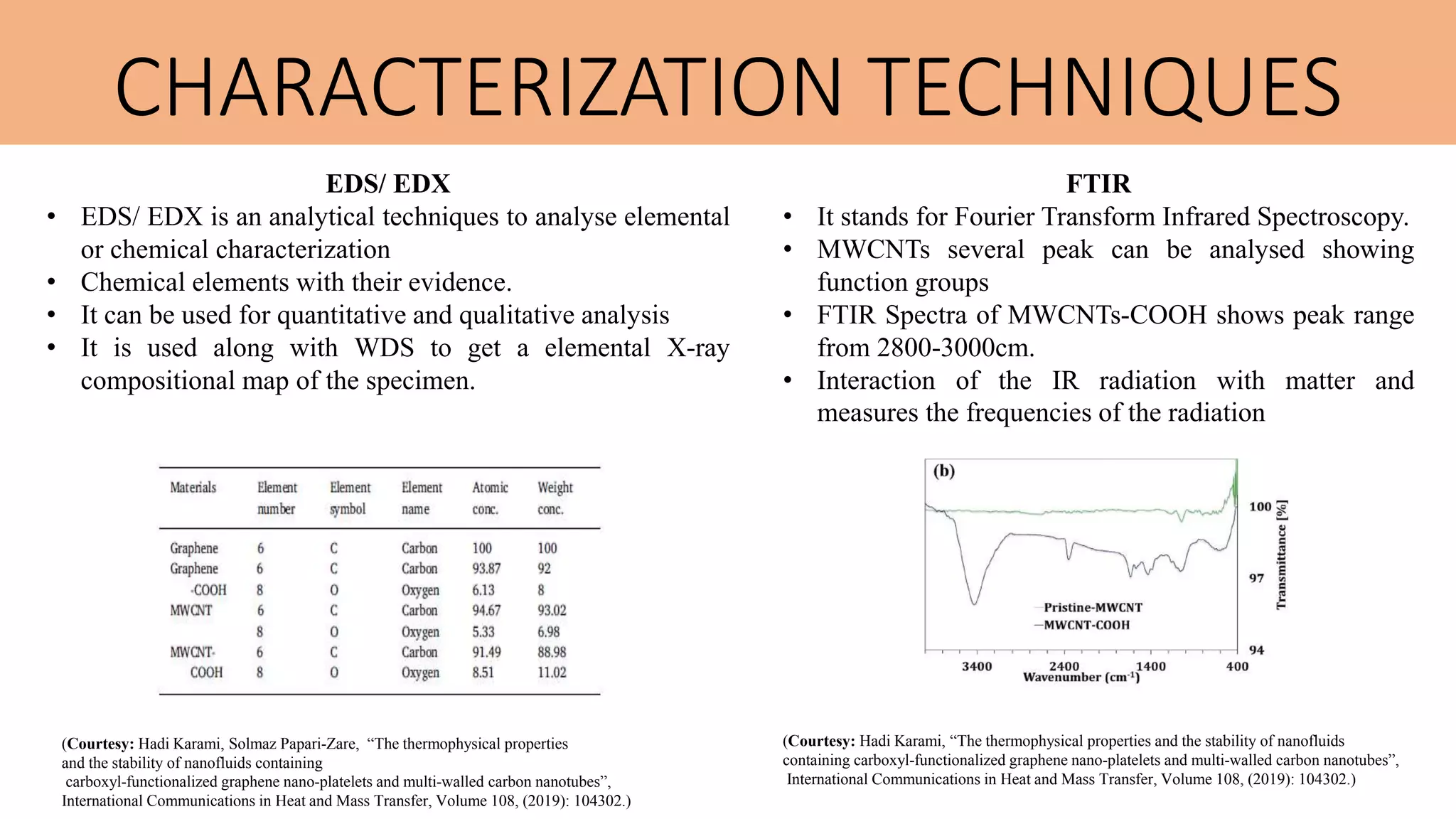

[1] Klaus Sattler, “Scanning Tunneling Microscopy of carbon nanotubes and nanocones, Carbon Nanotubes”, Pergamon, (1996):

65-70.

[2] J.-P. Issi, L. Langer, J. Heremans, “Electronic properties of carbon nanotubes: experimental results”, Carbon Nanotubes,

Pergamon, (1996): 121-128.

[3] Hadi Karami, Solmaz Papari-Zare, Mehdi Shanbedi, Chew Bee Teng, “The thermophysical properties and the stability of

nanofluids containing carboxyl-functionalized graphene nano-platelets and multi-walled carbon nanotubes”, International

Communications in Heat and Mass Transfer, Volume 108, (2019): 104302.

[4] Susan Liao, Guofu Xu, Wei Wang, Fumio Watari, Fuzhai Cui, Seeram Ramakrishna, Casey K. Chan, “Self-assembly of nano-

hydroxyapatite on multi-walled carbon nanotubes, Acta Biomaterialia”, Volume 3, Issue 5, (2007): 669-675.

[5] Christofer Hierold, Alain Jungen, Christoph Stampfer, Thomas Helbling, “Nano electromechanical sensors based on carbon

nanotubes”, Sensors and Actuators A: Physical, Volume 136, Issue 1, (2007): 51-61.

[6] J. Derakhshandeh, Y. Abdi, S. Mohajerzadeh, H. Hosseinzadegan, E. Asl. Soleimani, H. Radamson, “Fabrication of 100nm gate

length MOSFET's using a novel carbon nanotube-based nano-lithography”, Materials Science and Engineering: B, Volumes 124–

125, (2005): 354-358.

[7] Anastasiia Mikhalchan, Juan José Vilatela, “A perspective on high-performance CNT fibres for structural composites”, Carbon,

Volume 150, (2019): 191-215.

[8] Yuba Raj Poudel, Wenzhi Li, “Synthesis, properties, and applications of carbon nanotubes filled with foreign materials: a

review”, Materials Today Physics, Volume 7, (2018): 7-34.](https://image.slidesharecdn.com/presentationnano-191106192450/75/Carbon-Nanotubes-CNTs-Characterisation-and-Purification-methods-16-2048.jpg)