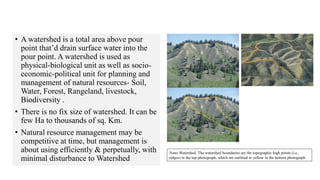

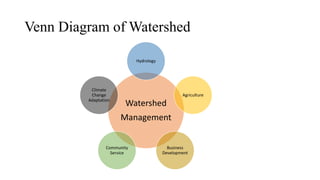

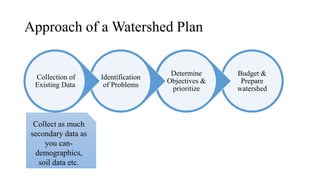

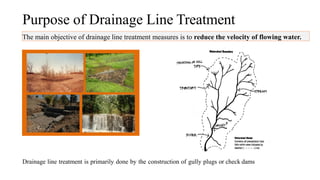

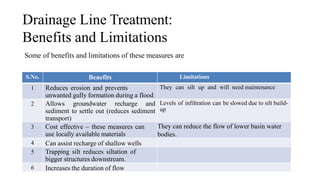

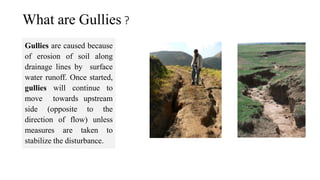

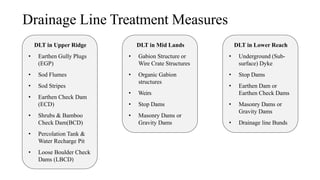

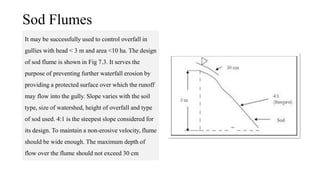

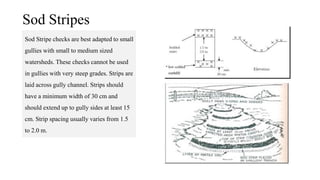

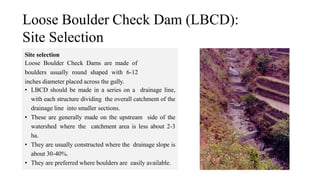

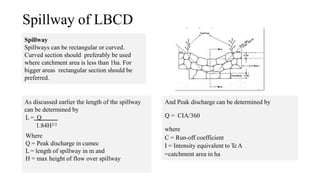

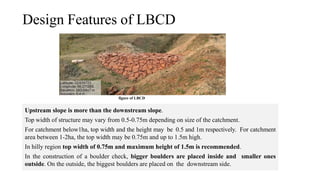

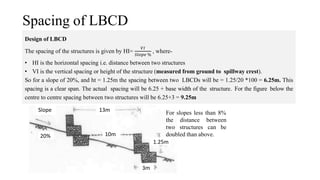

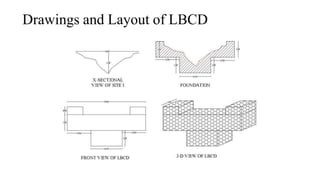

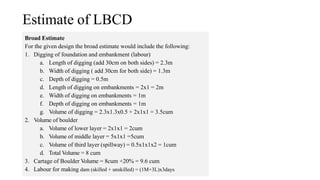

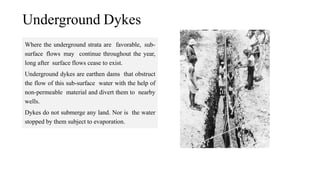

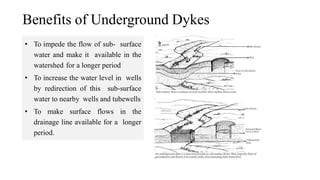

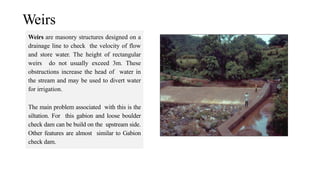

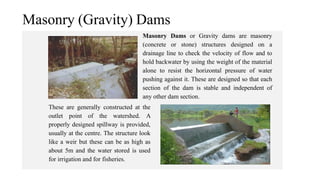

The document provides information about a NABARD training program on watershed projects. It begins with basic definitions related to watersheds and hydrology. It then discusses watershed management approaches, including area treatment, drainage treatment, capacity building, and implementation. Specific drainage line treatment measures are described such as gully plugs, check dams, sod flumes, and loose boulder check dams. Design principles, benefits and limitations of these structures are covered. Examples of designing loose boulder check dams are provided with details on spillway sizing and structure spacing.