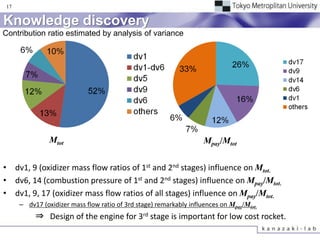

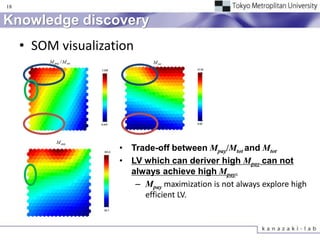

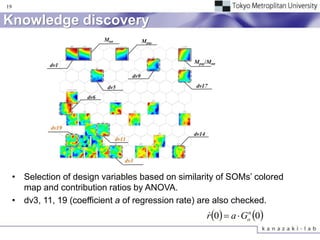

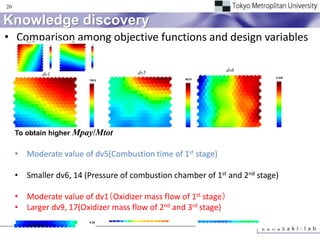

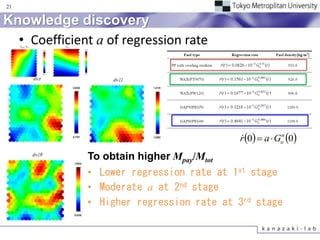

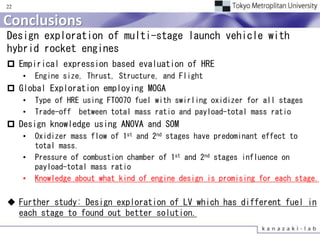

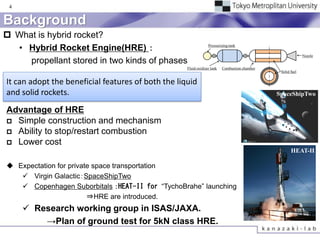

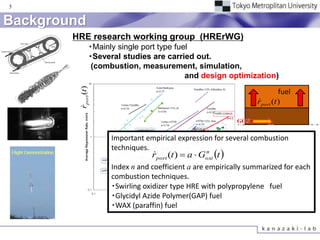

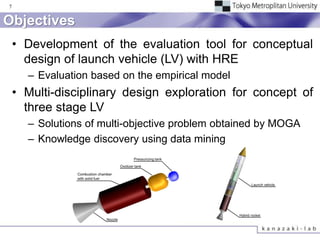

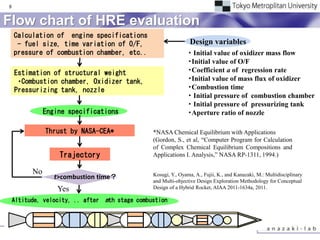

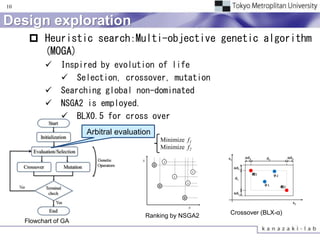

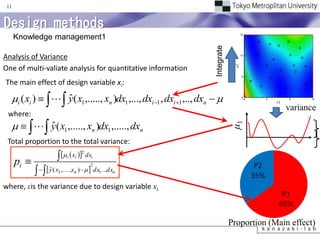

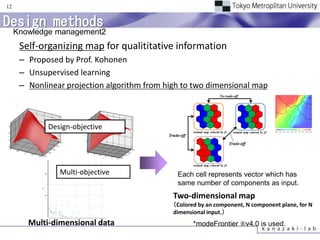

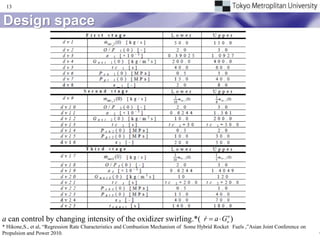

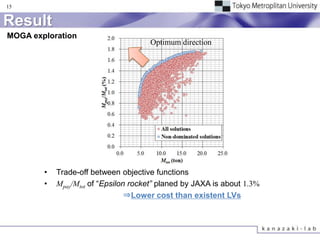

The document discusses a multi-disciplinary approach to conceptual design of a multi-stage hybrid rocket using methodologies such as genetic algorithms and data mining techniques. It highlights the advantages of hybrid rocket engines in terms of simple mechanisms and the ability to stop/restart combustion, while also emphasizing challenges in design and combustion characteristics. Key conclusions include the impact of oxidizer mass flow and combustion pressure on performance metrics such as payload-to-total mass ratio.

![16

Selected Design from Non-dominated Solutions

Selected rocket size

Length of rocket [m] 20.8

Diameter of rocket [m] 1.46

Aspect ratio of rocket [-] 14.3

1st stage 2nd stage 3rd stage

Length [m] 8.22 6.57 6.06

Diameter [m] 1.45 1.46 1.07

Gross mass [ton] 8.07 4.09 0.70

Structural mass [ton] 1.78 0.49 0.10

Structural mass ratio [%] 22.1 11.9 14.5

20.8

8.22 6.57 6.06

1.35 1.36 0.97

1.46

What kind of design can be high performance?

1.21 2.18 3.21 1.61 2.29 1.06 2.11 1.11 2.06 0.35 0.99 0.64 2.02

⇒Design knowledge discovery by means of data mining](https://image.slidesharecdn.com/120913eccomsppt-121127205635-phpapp02/85/Multi-Disciplinary-Conceptual-Design-of-Multi-Stage-Hybrid-Rocket-using-Genetic-Algorithm-and-Data-Mining-Technique-16-320.jpg)