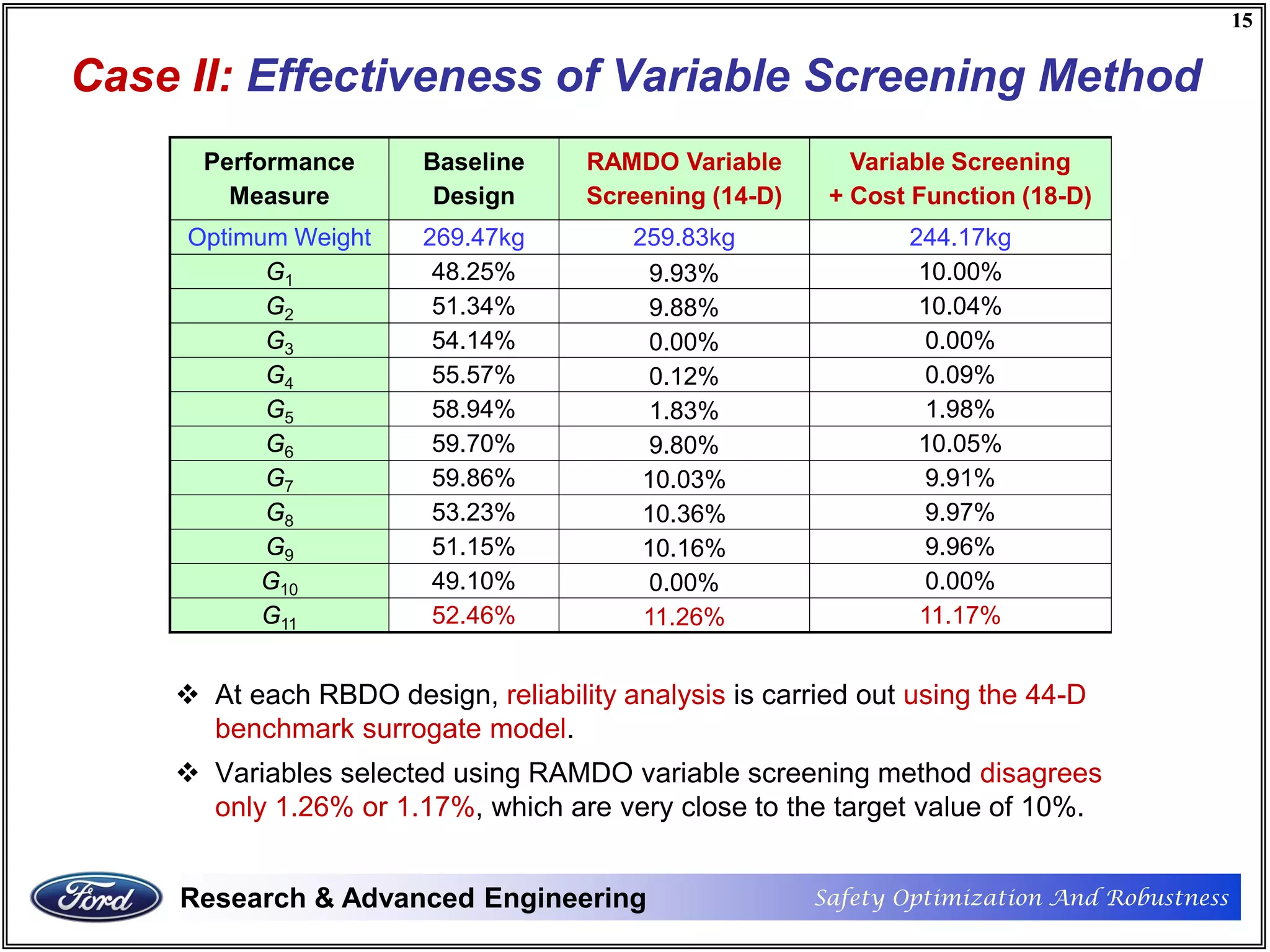

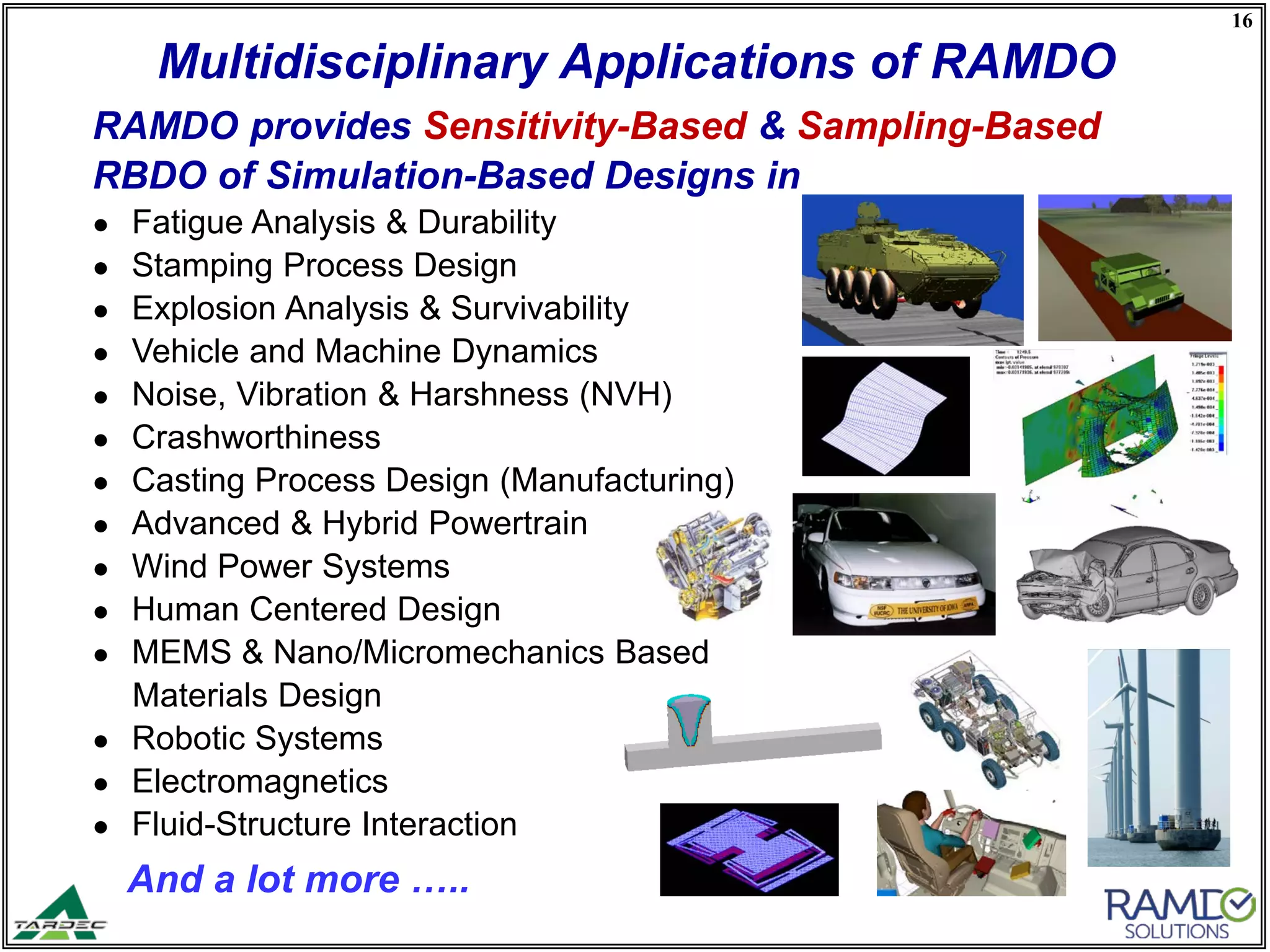

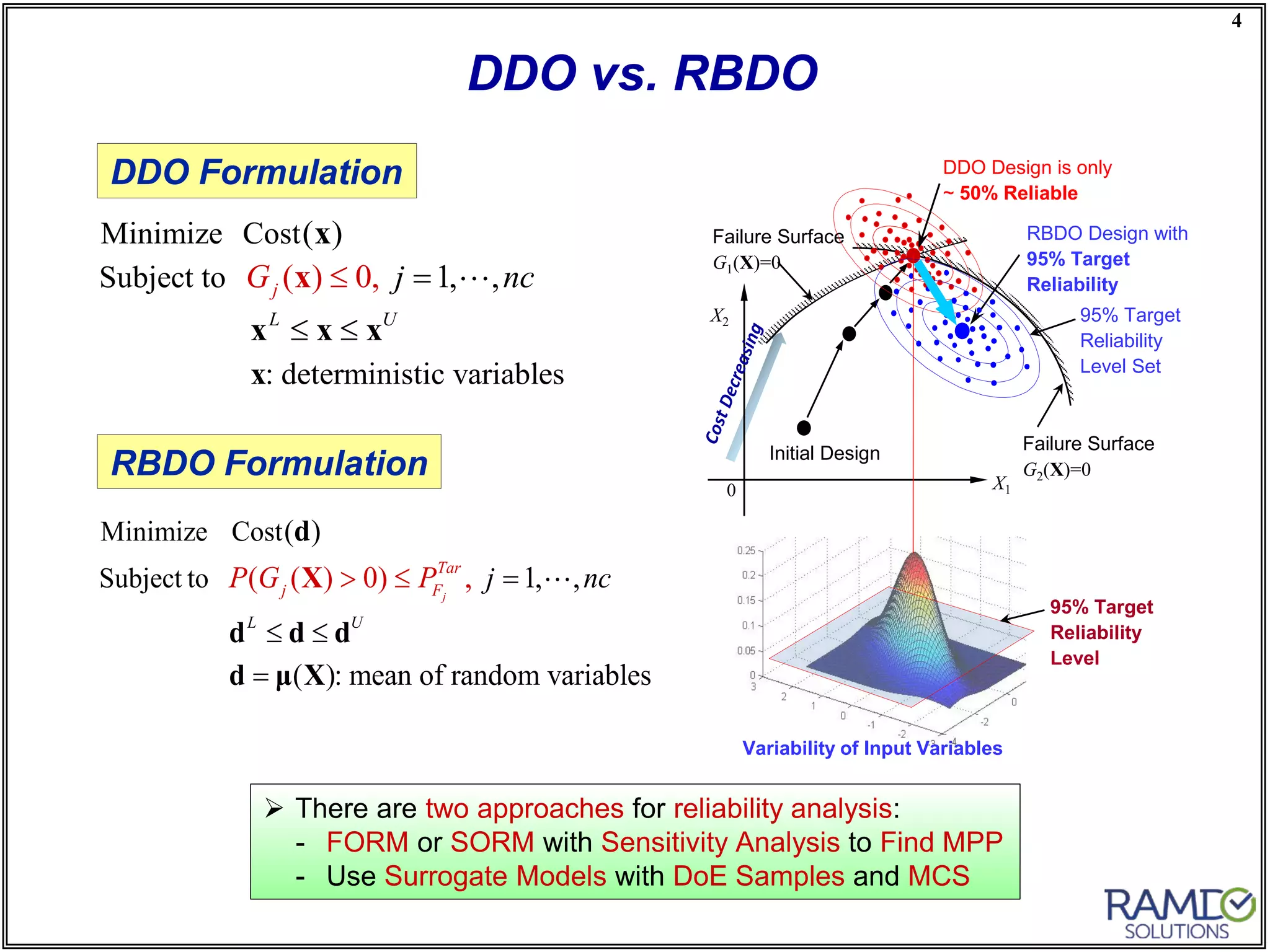

This document summarizes the capabilities of the RAMDO software for reliability-based design optimization (RBDO). It discusses both sensitivity-based and sampling-based RBDO approaches in RAMDO. It also provides examples of multidisciplinary applications of RAMDO in areas like fatigue analysis, casting process design, vehicle crashworthiness, and more. Several published case studies demonstrate how RAMDO has been used to optimize designs while accounting for input variability and reliability constraints.

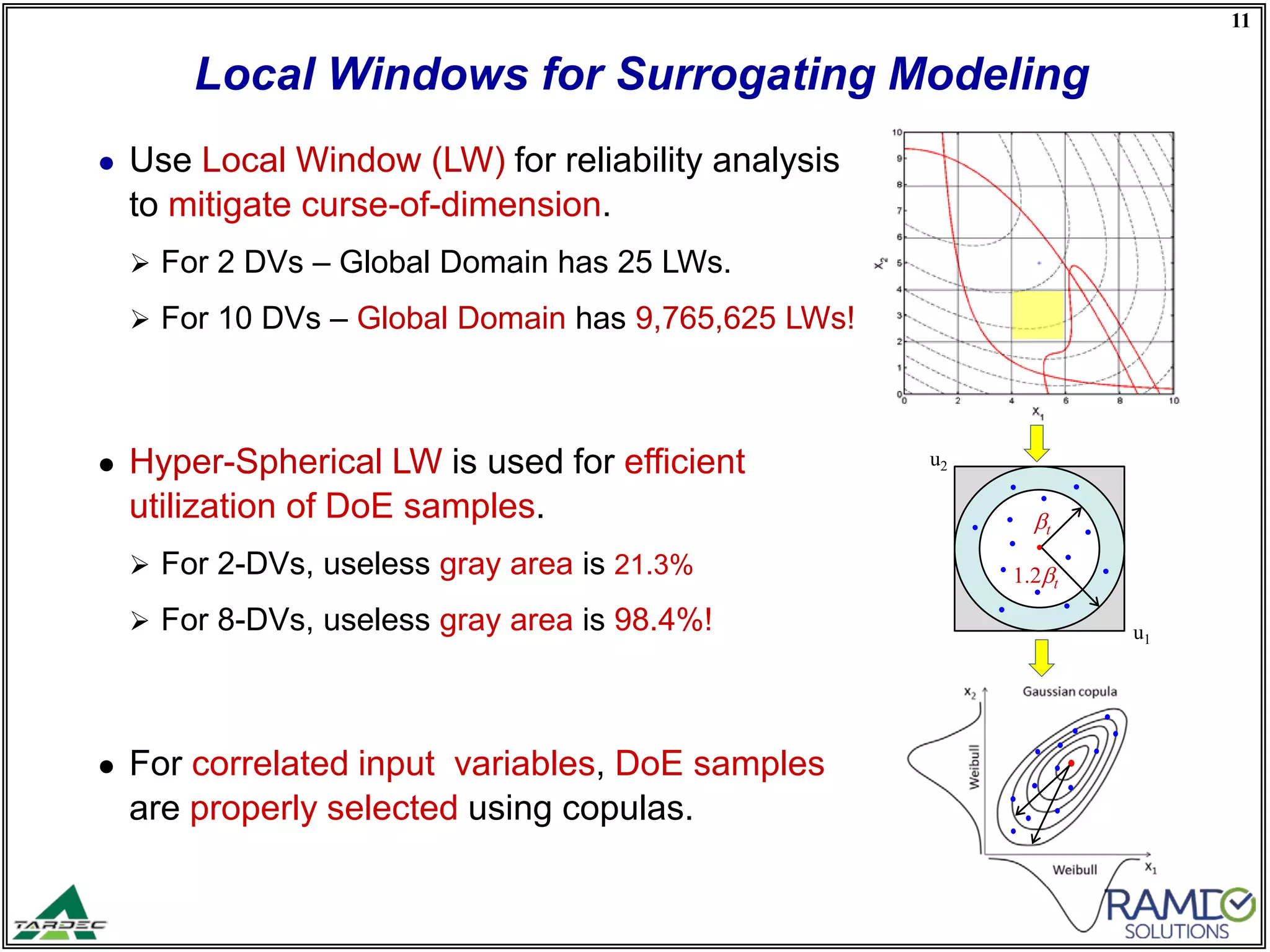

![3

Input Variables

X=[X1, X2,…, Xn]

Output

Performances

G(X)=[G1,.., Gnc]

Multidisciplinary Simulation with Input Variability

Output

Performances G(X)

Output Variability of

Performance G1(X)

Output Variability of

Performance Gnc(X)

Input Variables X

Load

Variability

Manufacturing

Variability

Surrogate

Modeling

Variability

Material

Property

Variability

Other Input

Variable

Variabilities

Casting

Process

Variability

RAMDO will stimulate collaboration

among Design, Manufacturing &

Testing Engineers.

FEA

Multibody

Dynamics

CFD

Casting

Electromagnetics

Reliability](https://image.slidesharecdn.com/b8zyxcnqraiwtxk9a1gf-signature-7450a6129d2a9406eeb061265db9426e6b34389f83719b743ccfba18af4ea508-poli-150602201008-lva1-app6891/75/Development-of-Reliability-Analysis-and-Multidisciplinary-Design-Optimization-RAMDO-Software-3-2048.jpg)

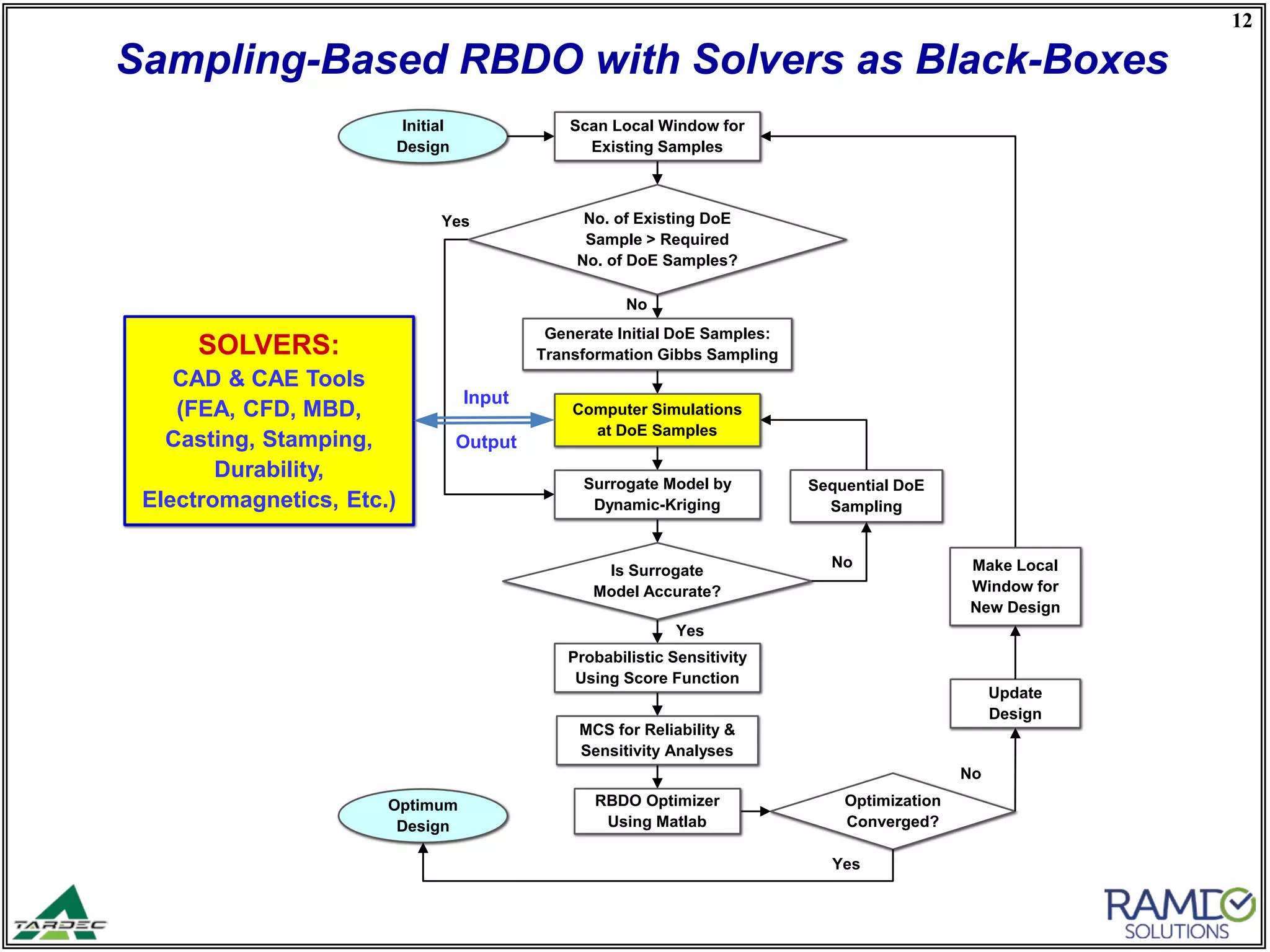

![10

Dynamic Kriging (DKG) Surrogate Models

● In standard Kriging model, the responses are represented by

where is the regression coefficient, is polynomial basis

function and is a model of Gaussian random process with

zero mean and covariance .

● Select best mean structure from 0th, 1st, and 2nd order

polynomials using cross validation (CV) error.

● Select best correlation model from 7 candidates using

maximum likelihood estimation.

● Provides 7×3 = 21 options for surrogate models on each local

window.

( , , )i jR θ x x

( )k

f x

, =[ ( ), 1,..., , 1,..., ]n Kik

f k K i n ×= =y =Fβ+Z F x

2

( , ) ( , , )i j i jC Rσ=x x θ x x

1K×β

1n×Z](https://image.slidesharecdn.com/b8zyxcnqraiwtxk9a1gf-signature-7450a6129d2a9406eeb061265db9426e6b34389f83719b743ccfba18af4ea508-poli-150602201008-lva1-app6891/75/Development-of-Reliability-Analysis-and-Multidisciplinary-Design-Optimization-RAMDO-Software-10-2048.jpg)