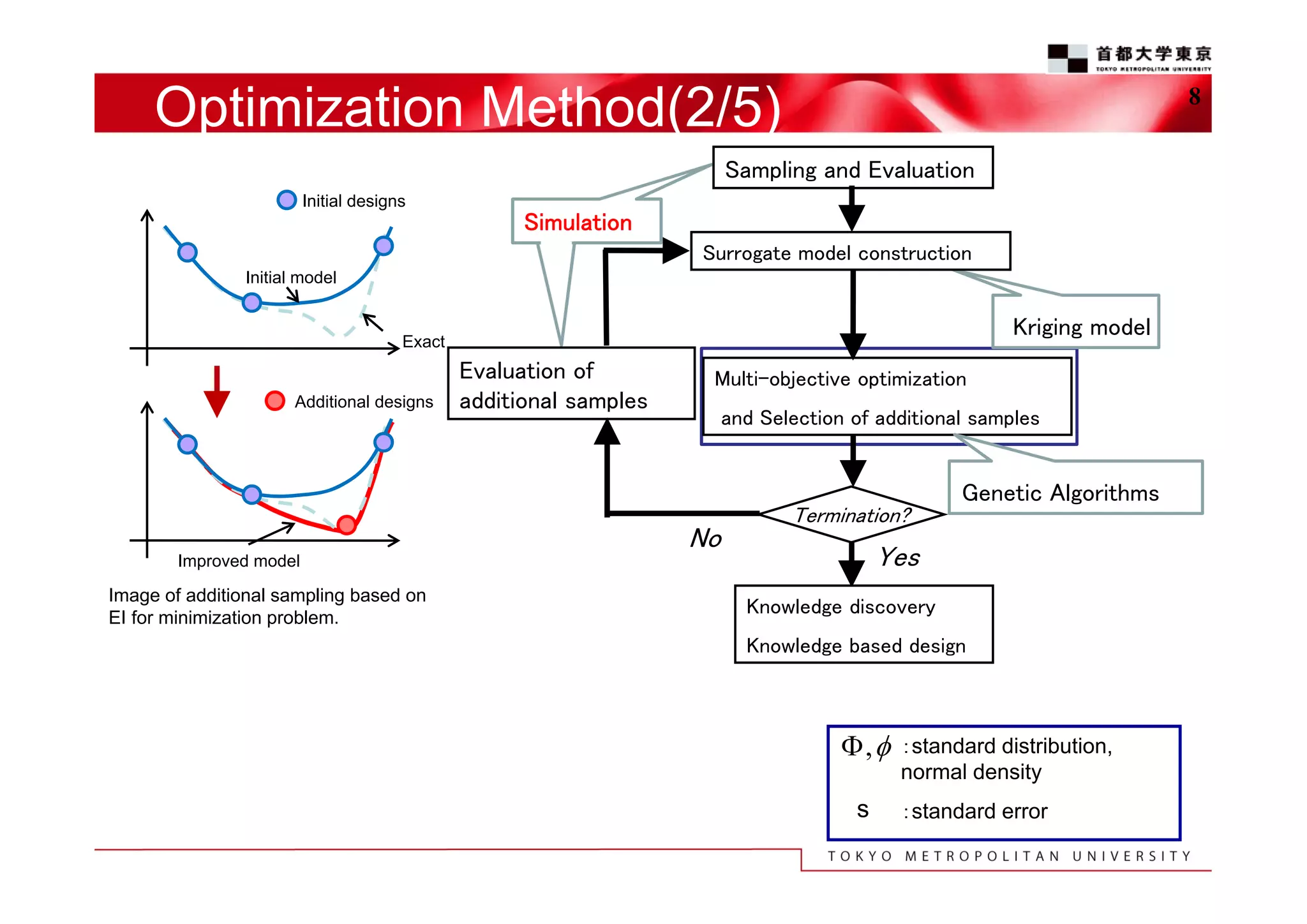

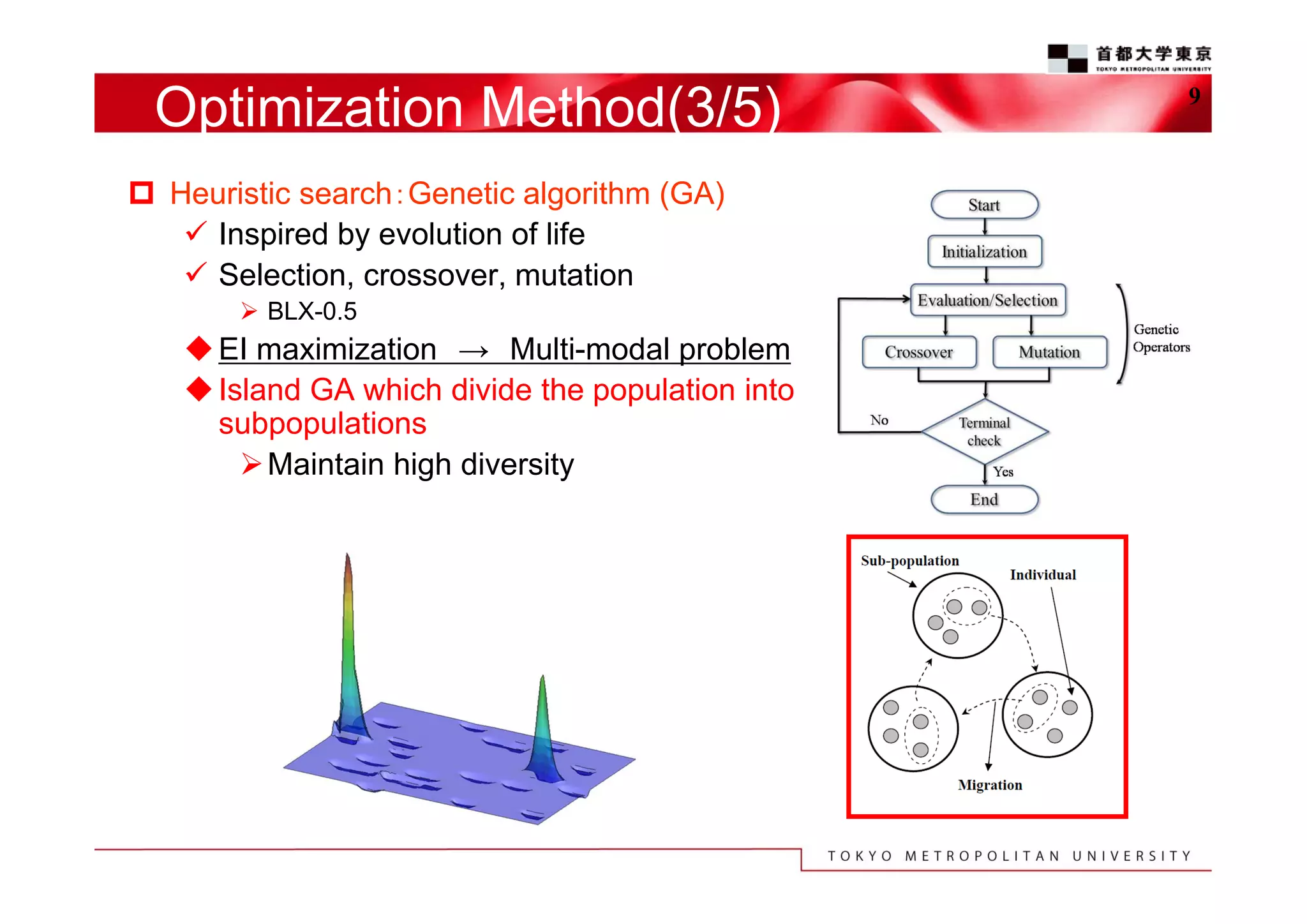

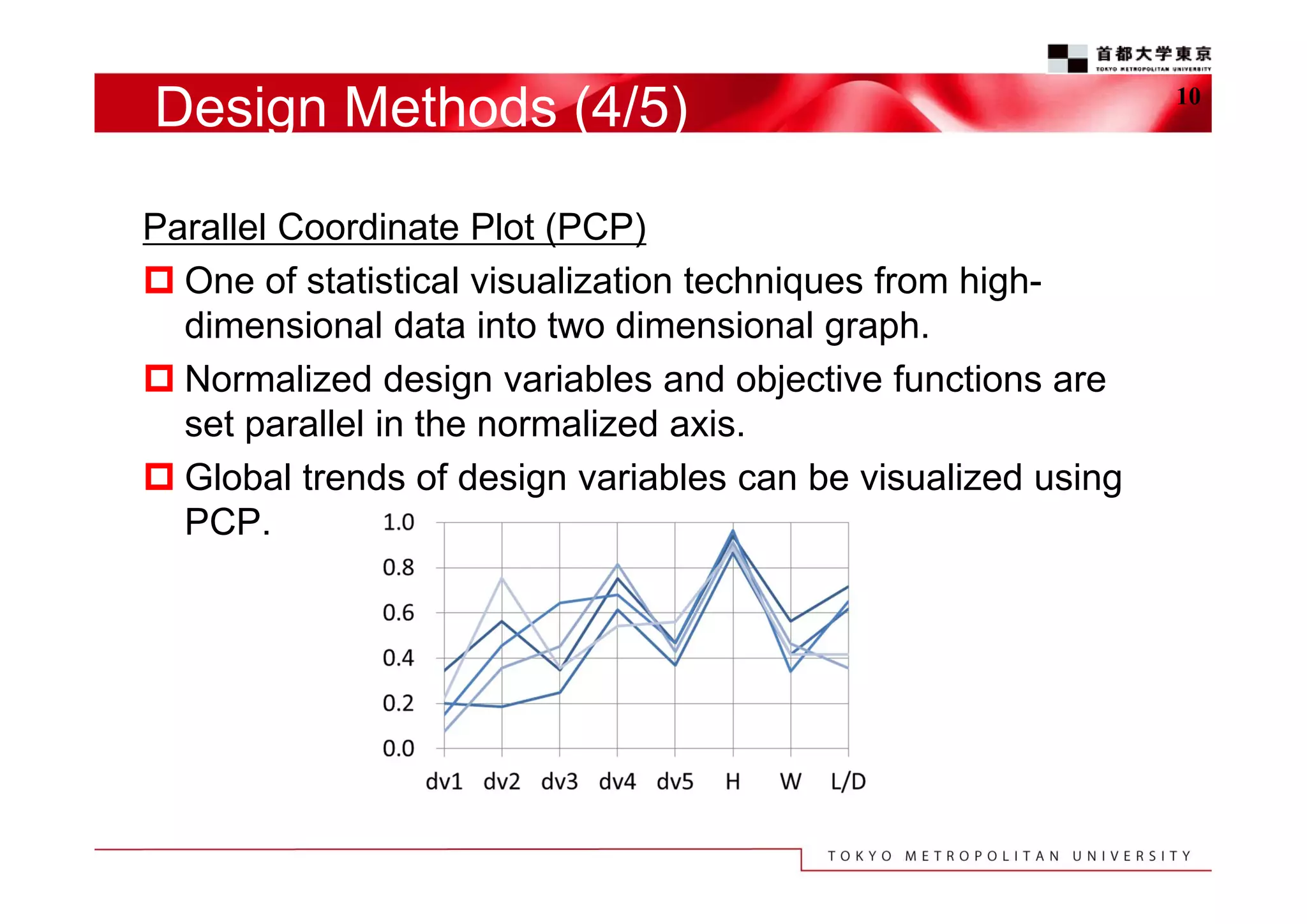

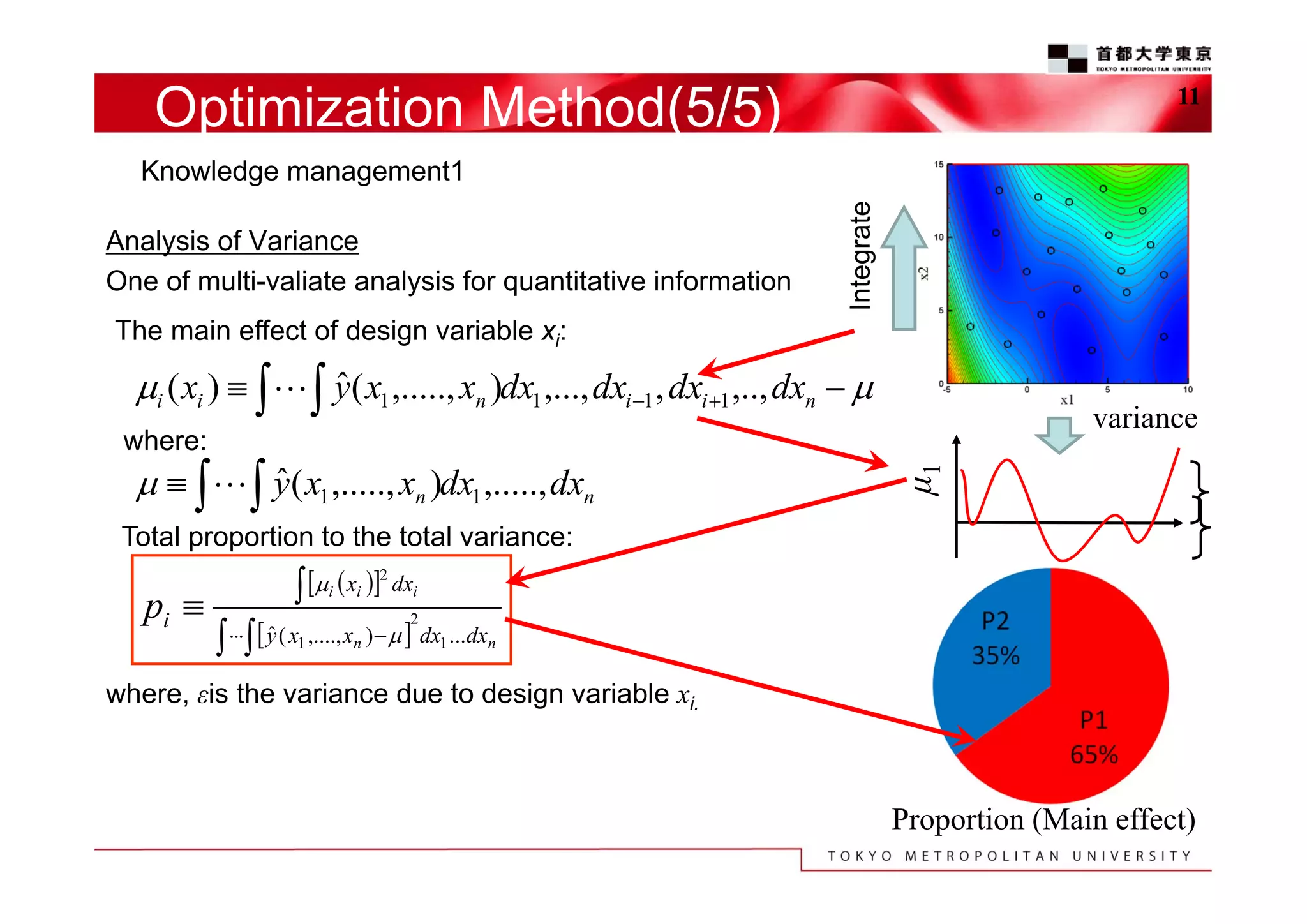

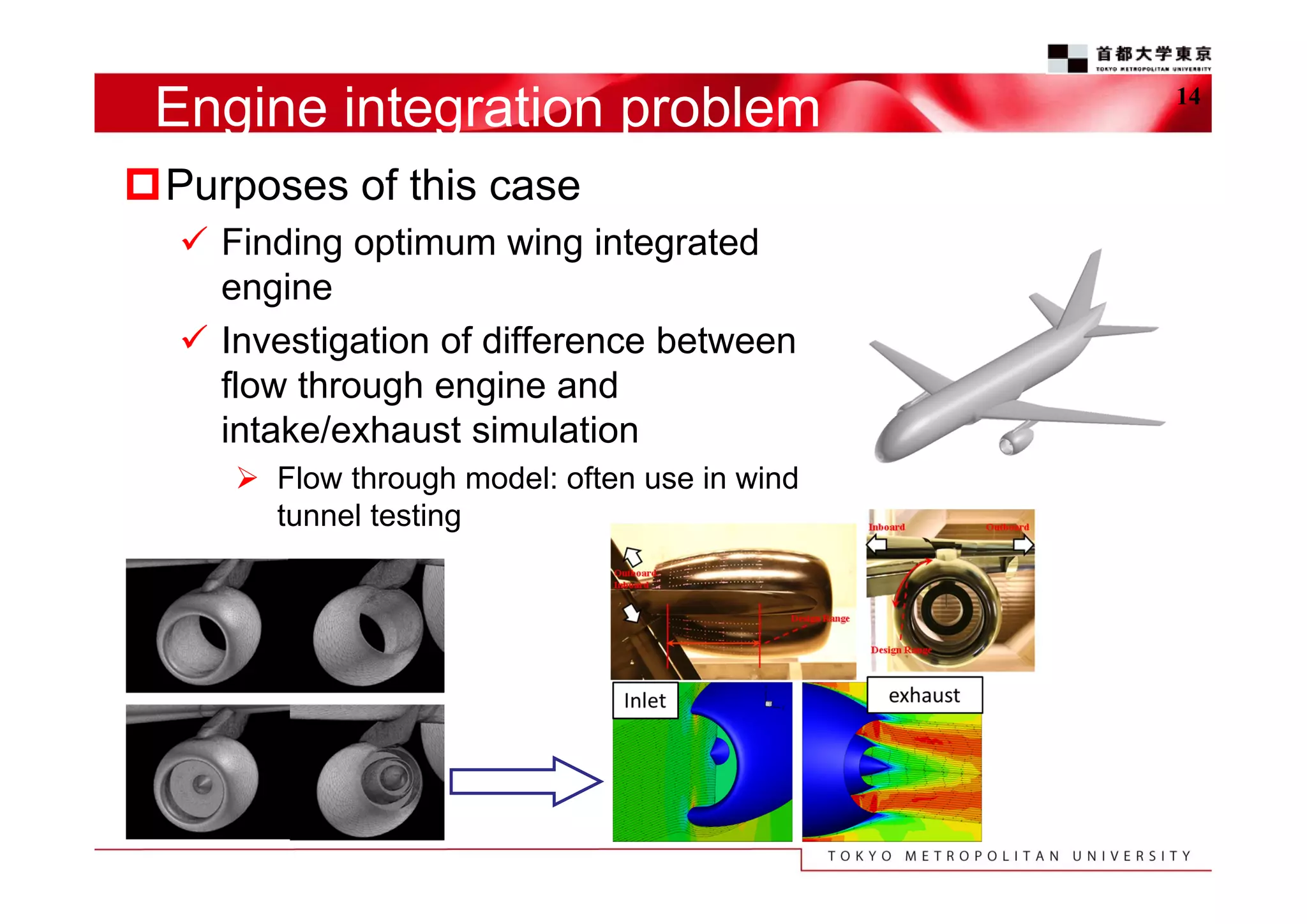

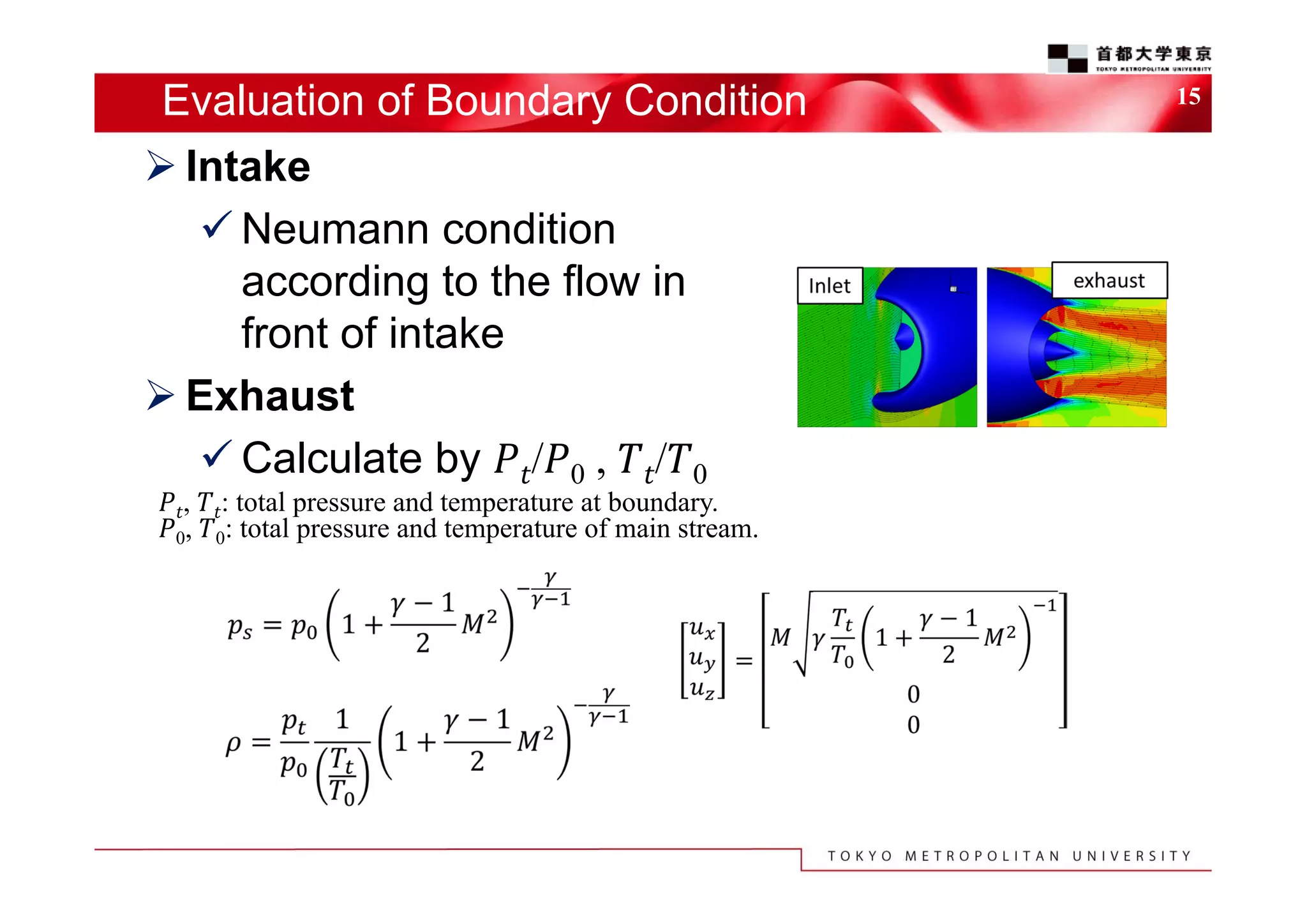

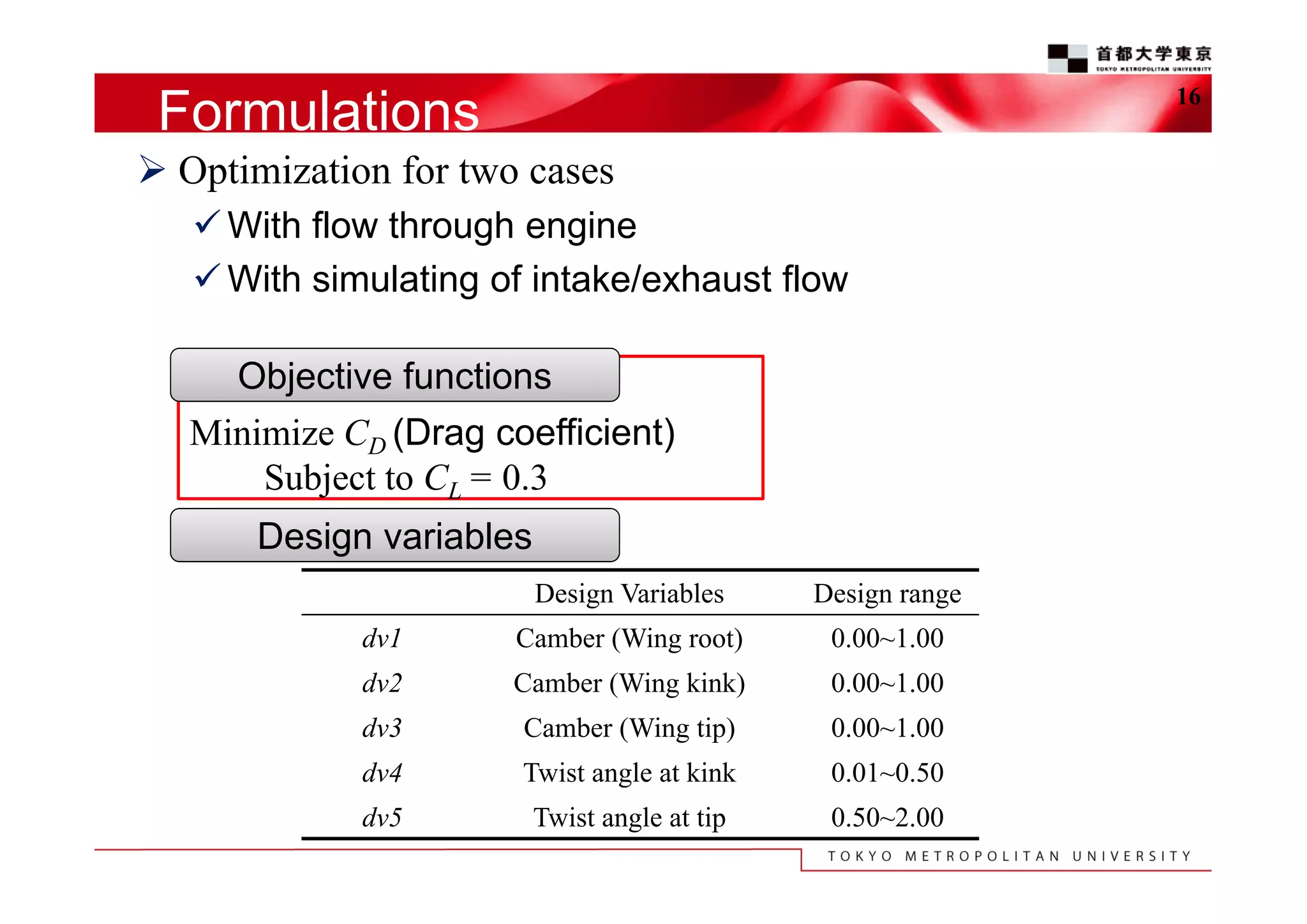

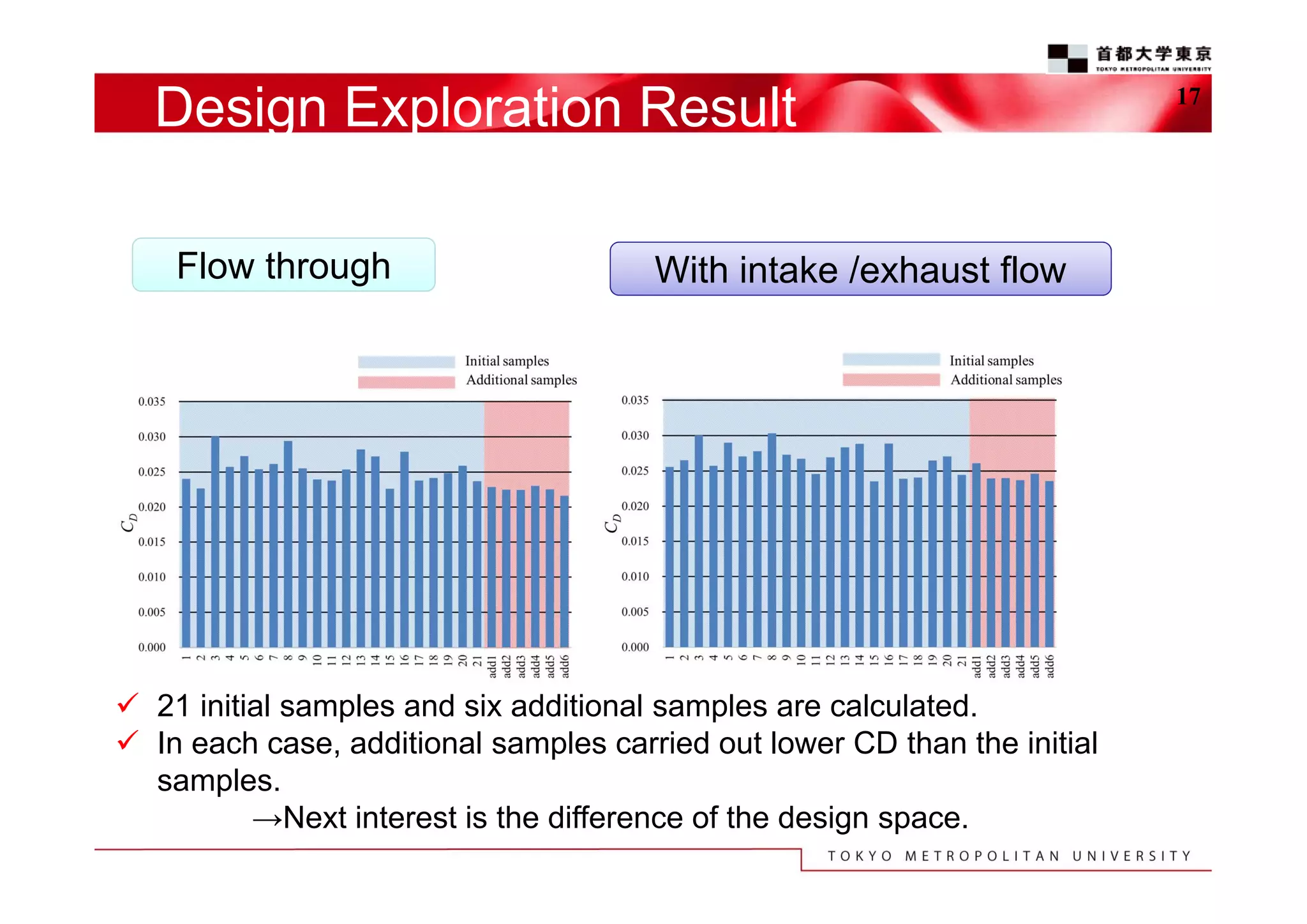

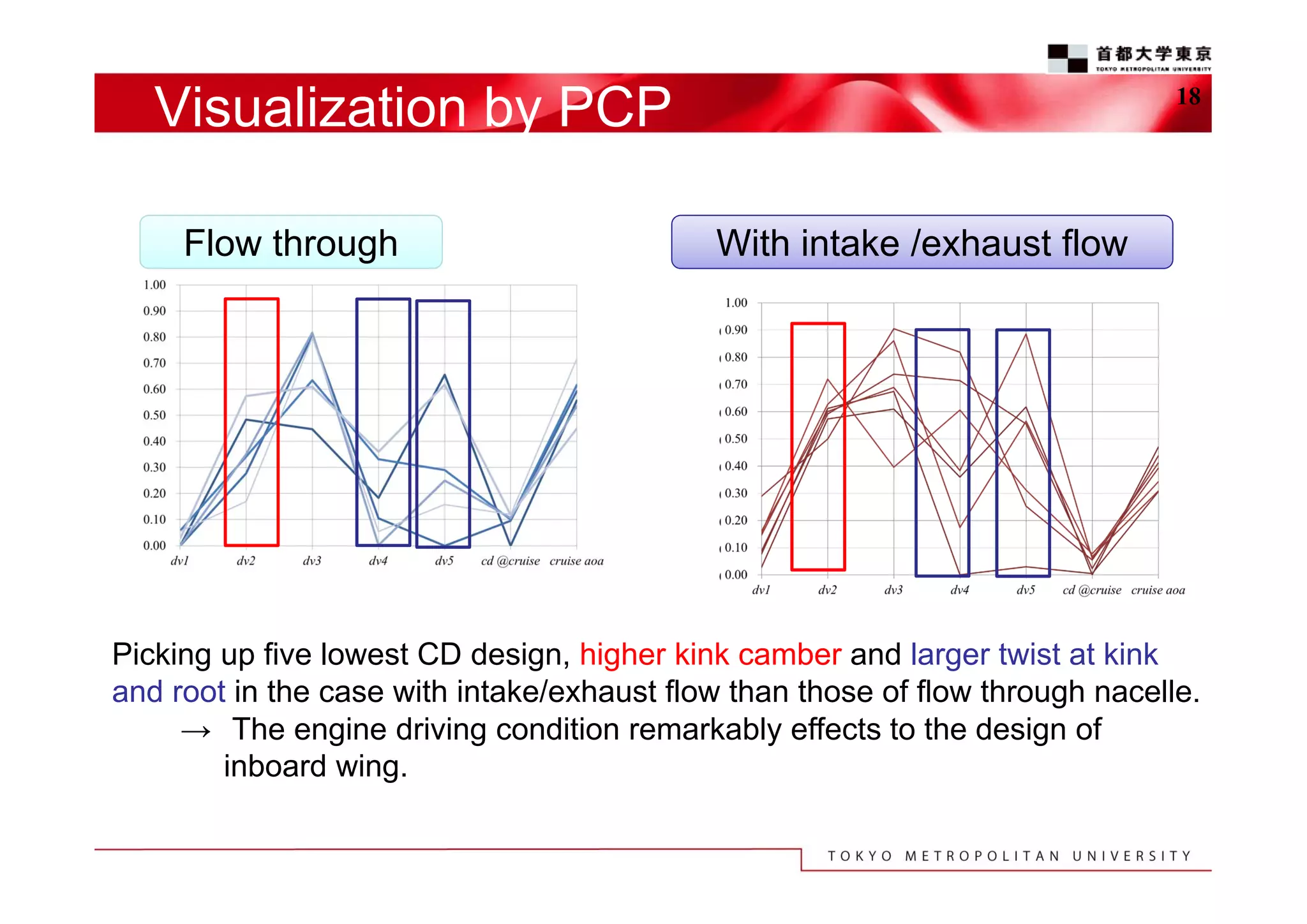

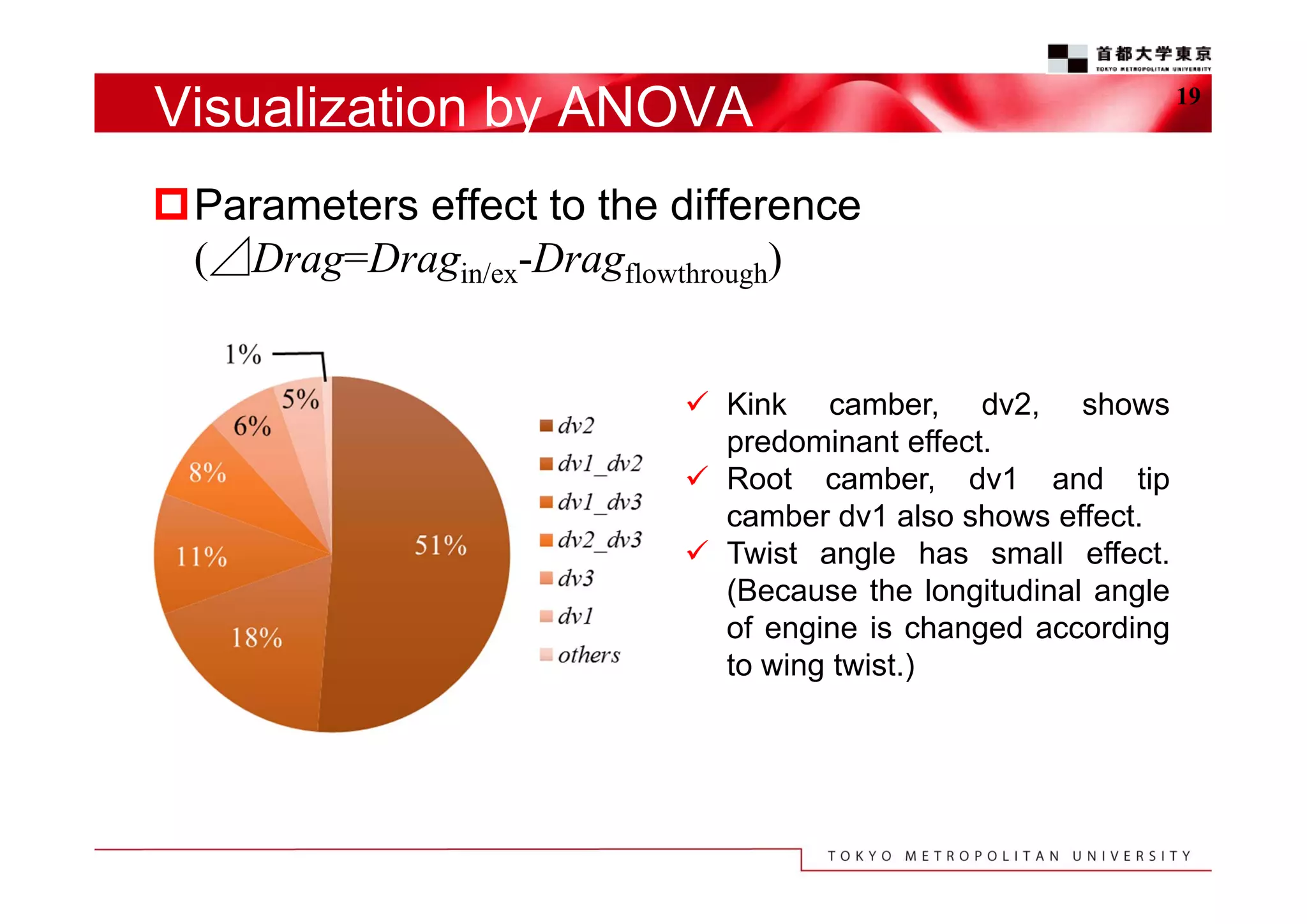

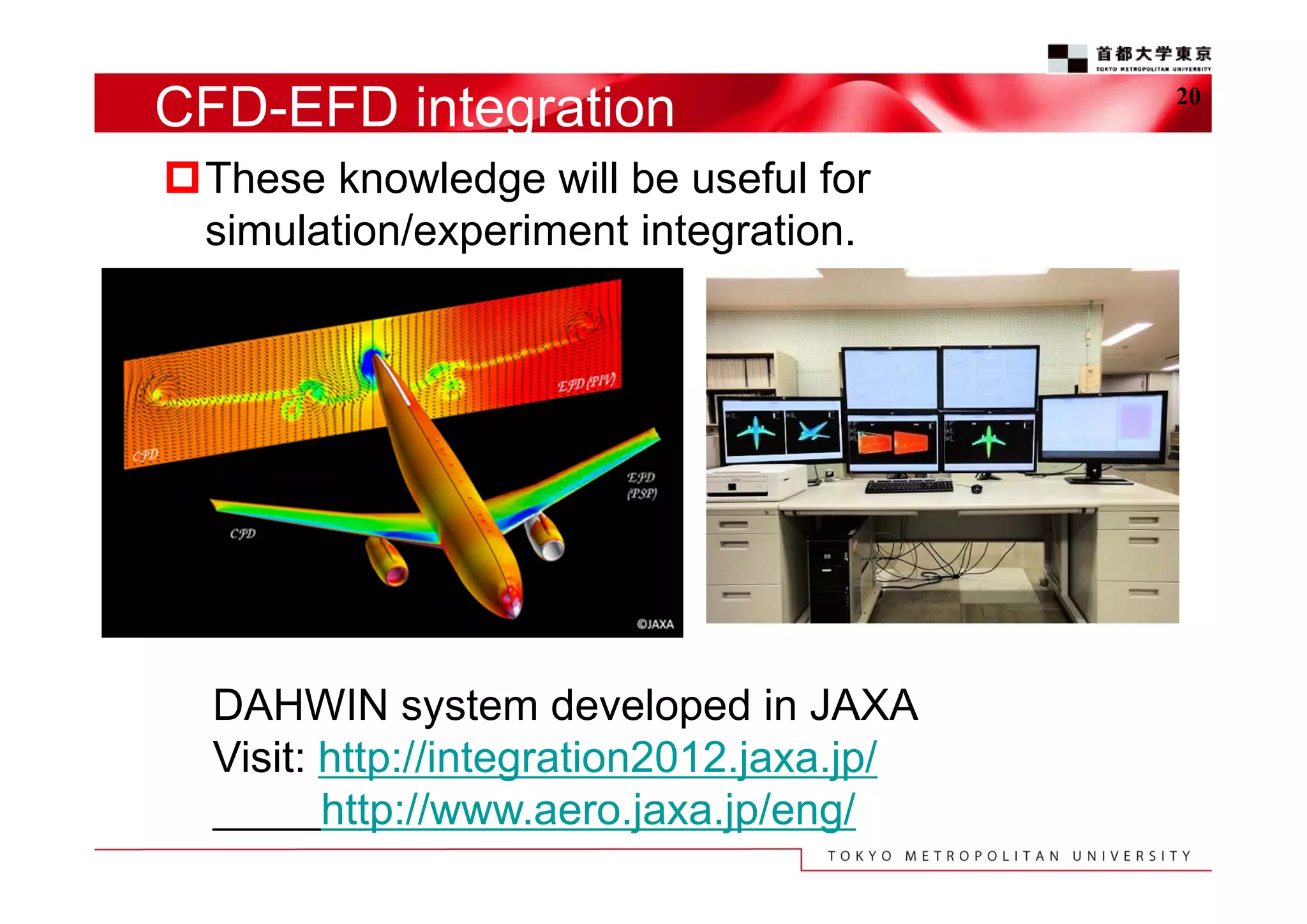

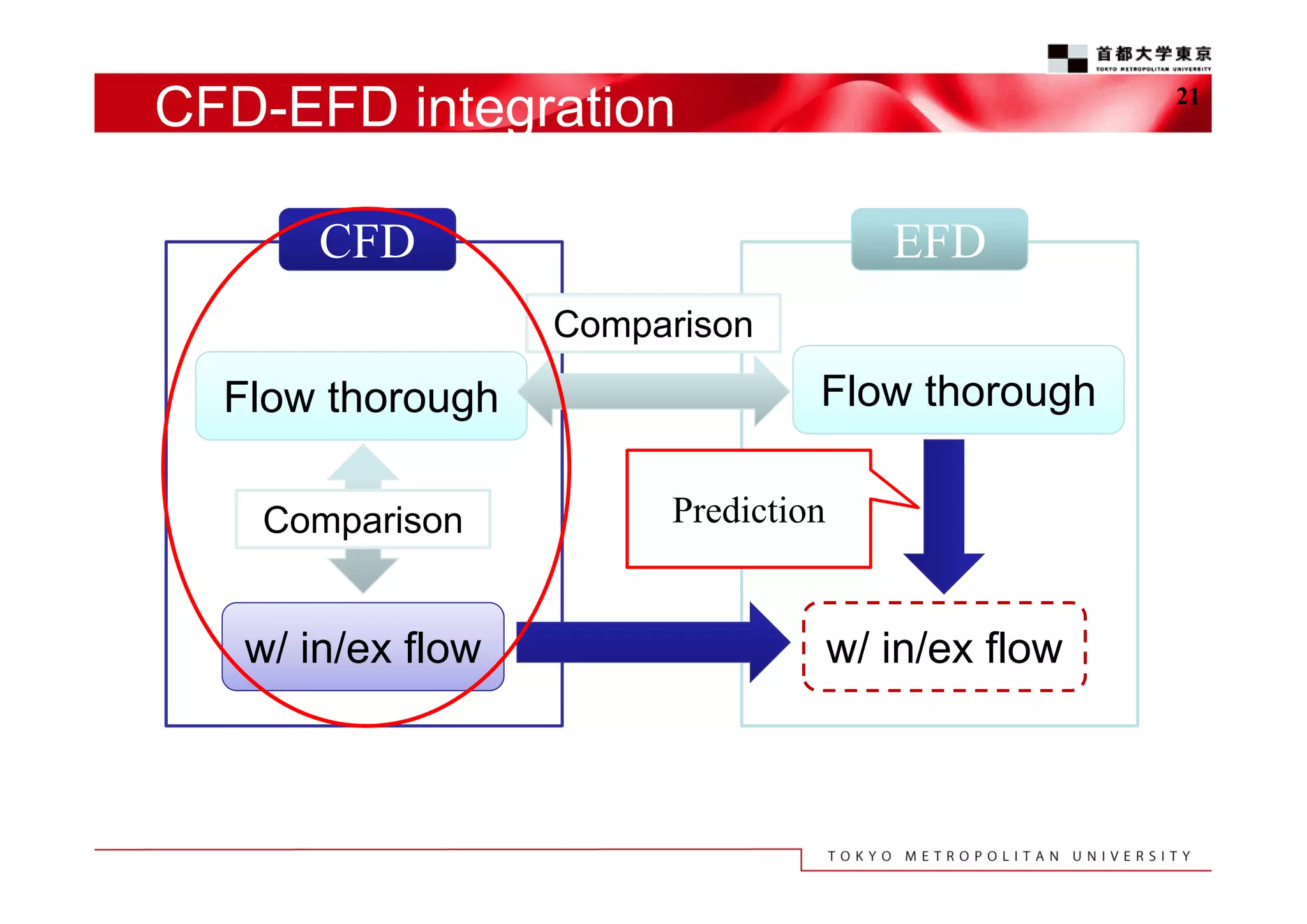

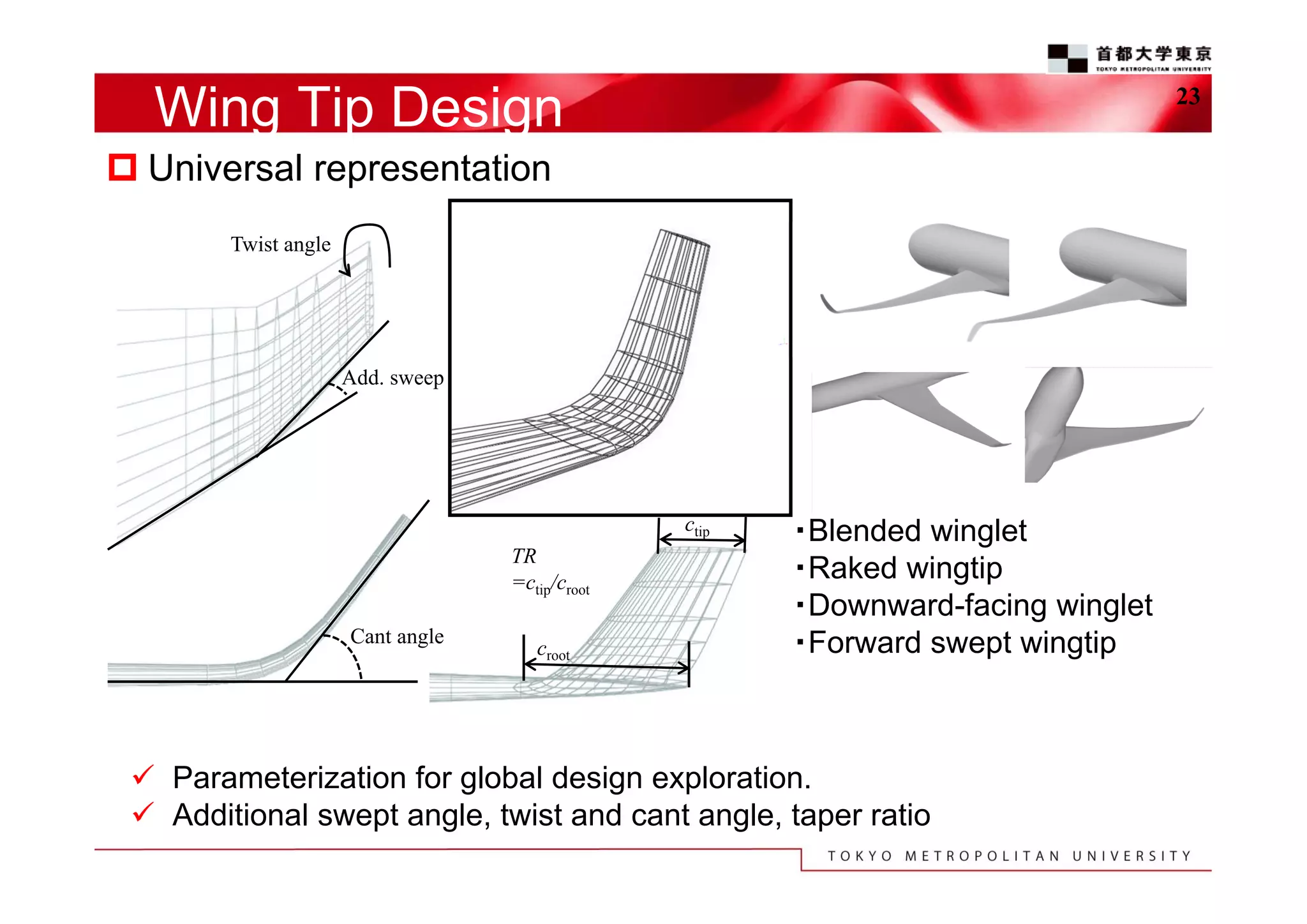

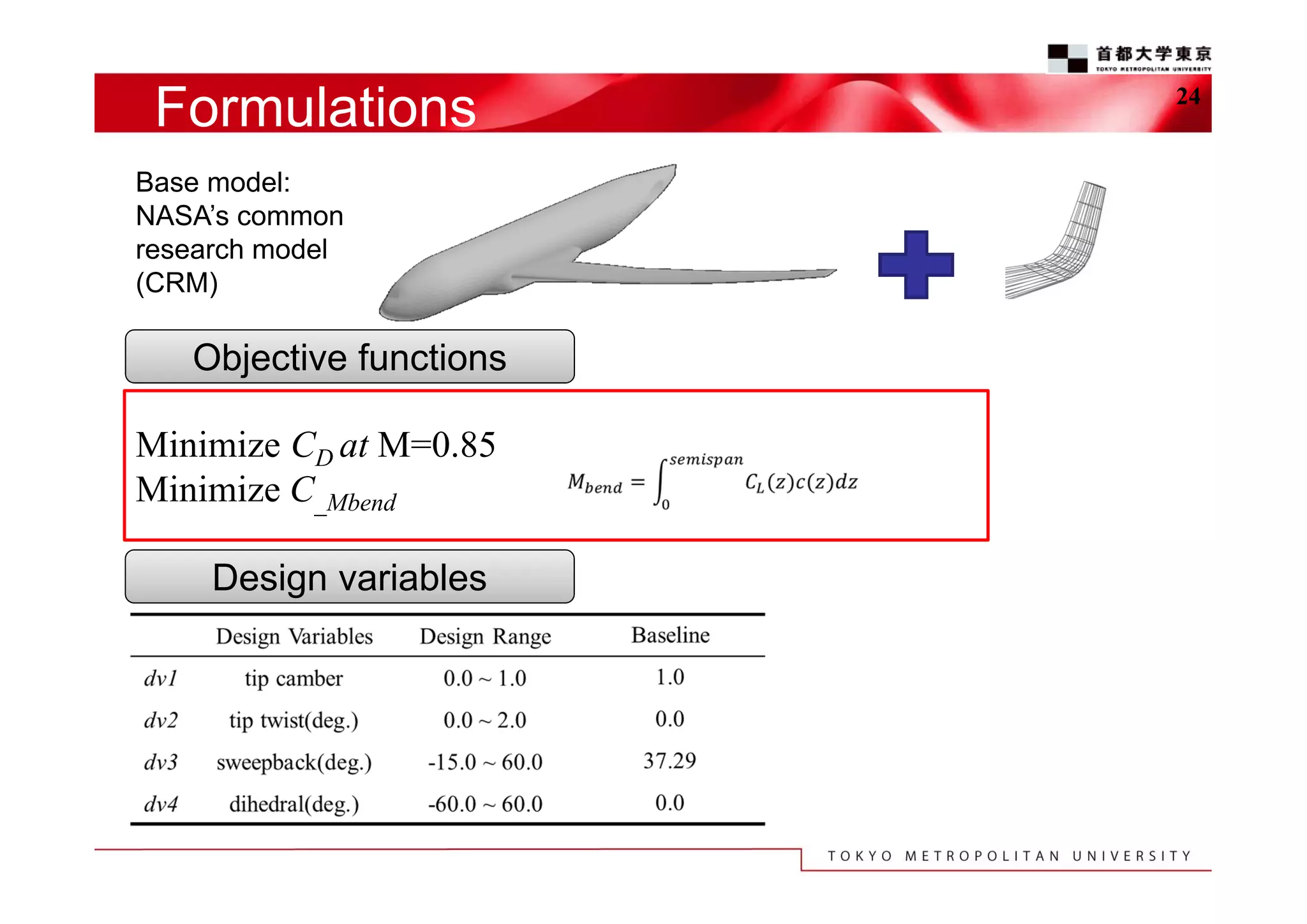

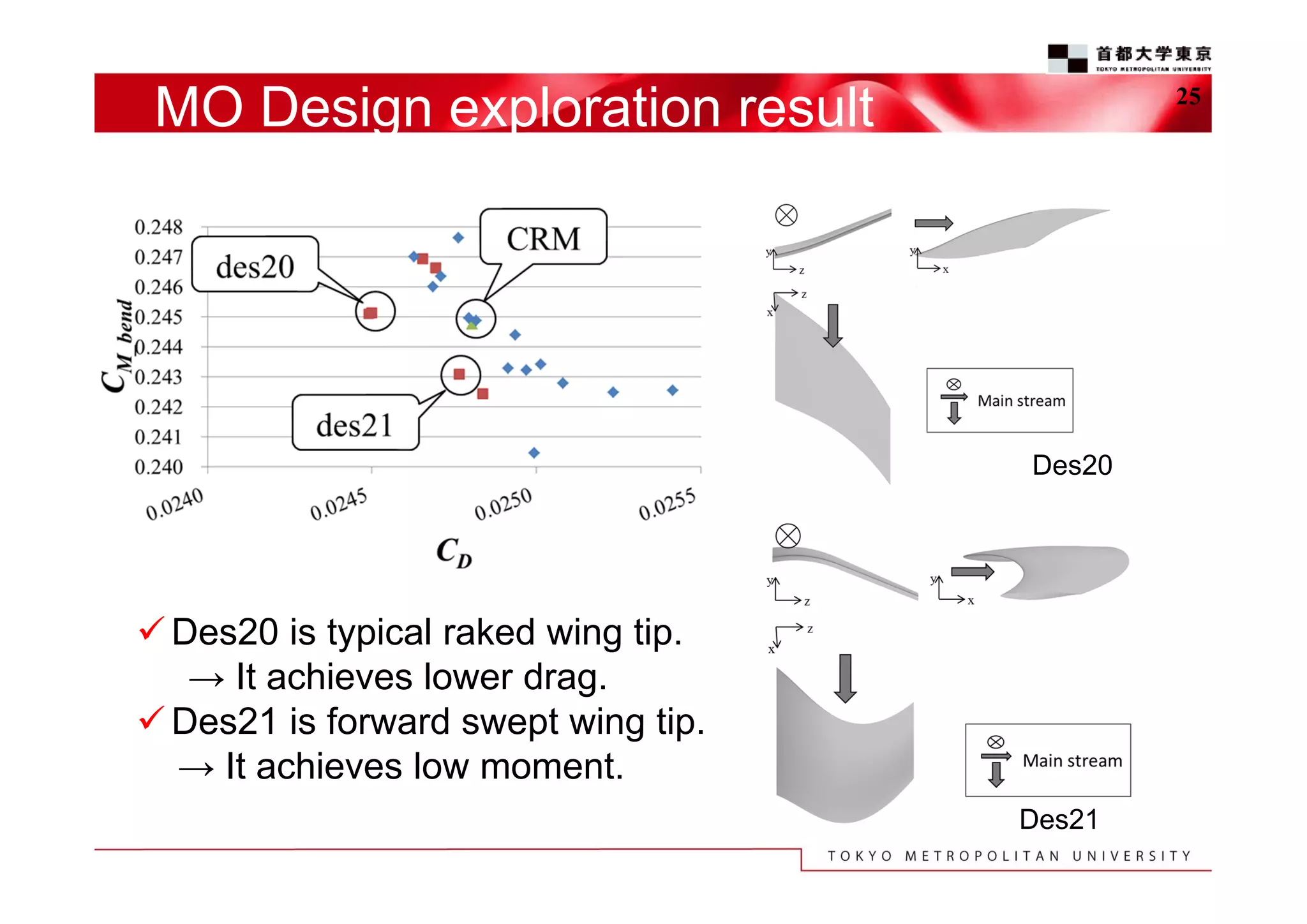

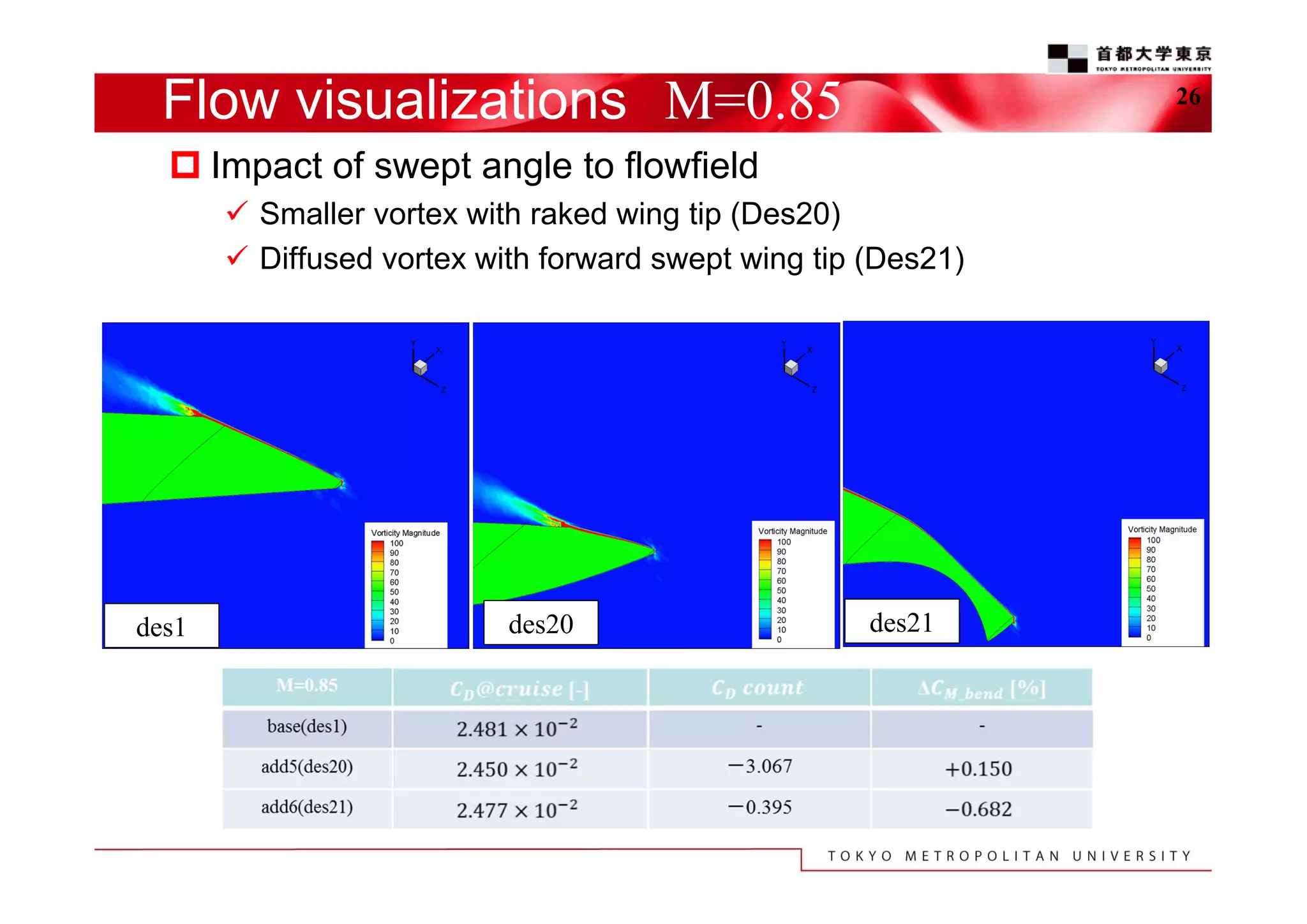

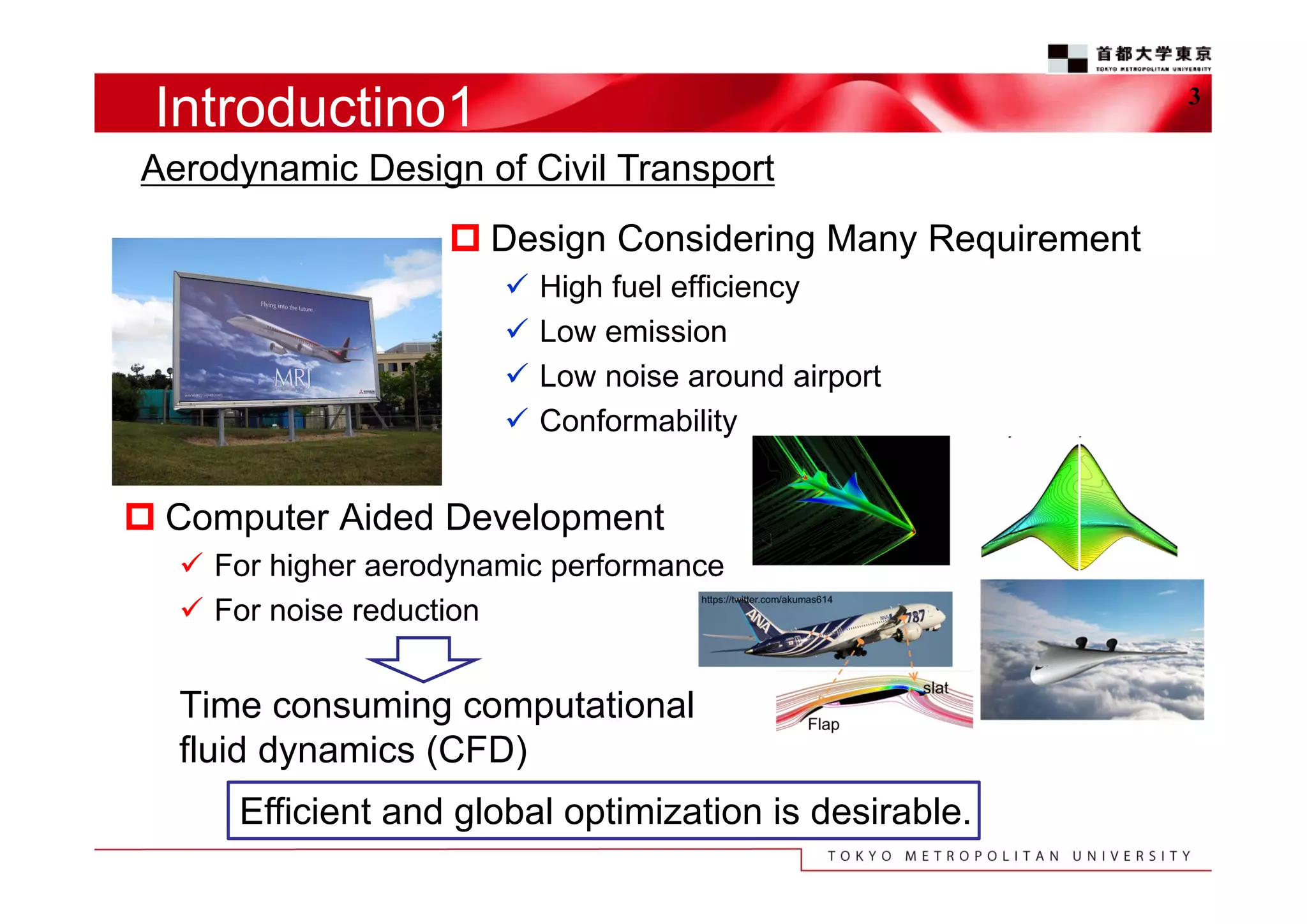

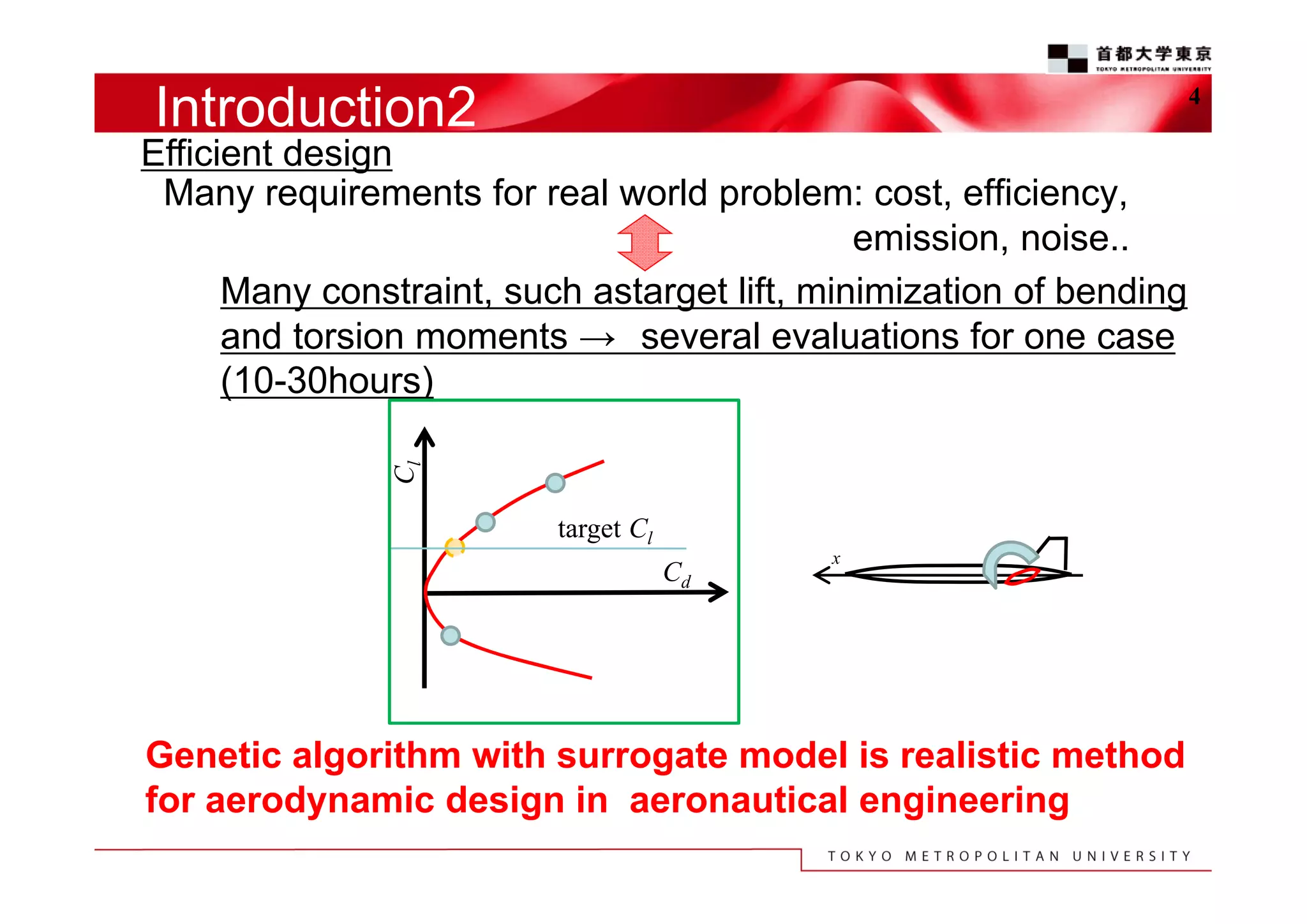

The document discusses the efficient design exploration for civil aircraft using a kriging-based genetic algorithm. It presents two case studies focused on optimizing the aerodynamic design of a wing integrated engine nacelle and multi-disciplinary design of wing tips, employing efficient global optimization methods. The findings emphasize the significance of design variables affecting drag and the importance of integrating knowledge discovery techniques for enhancing design processes.

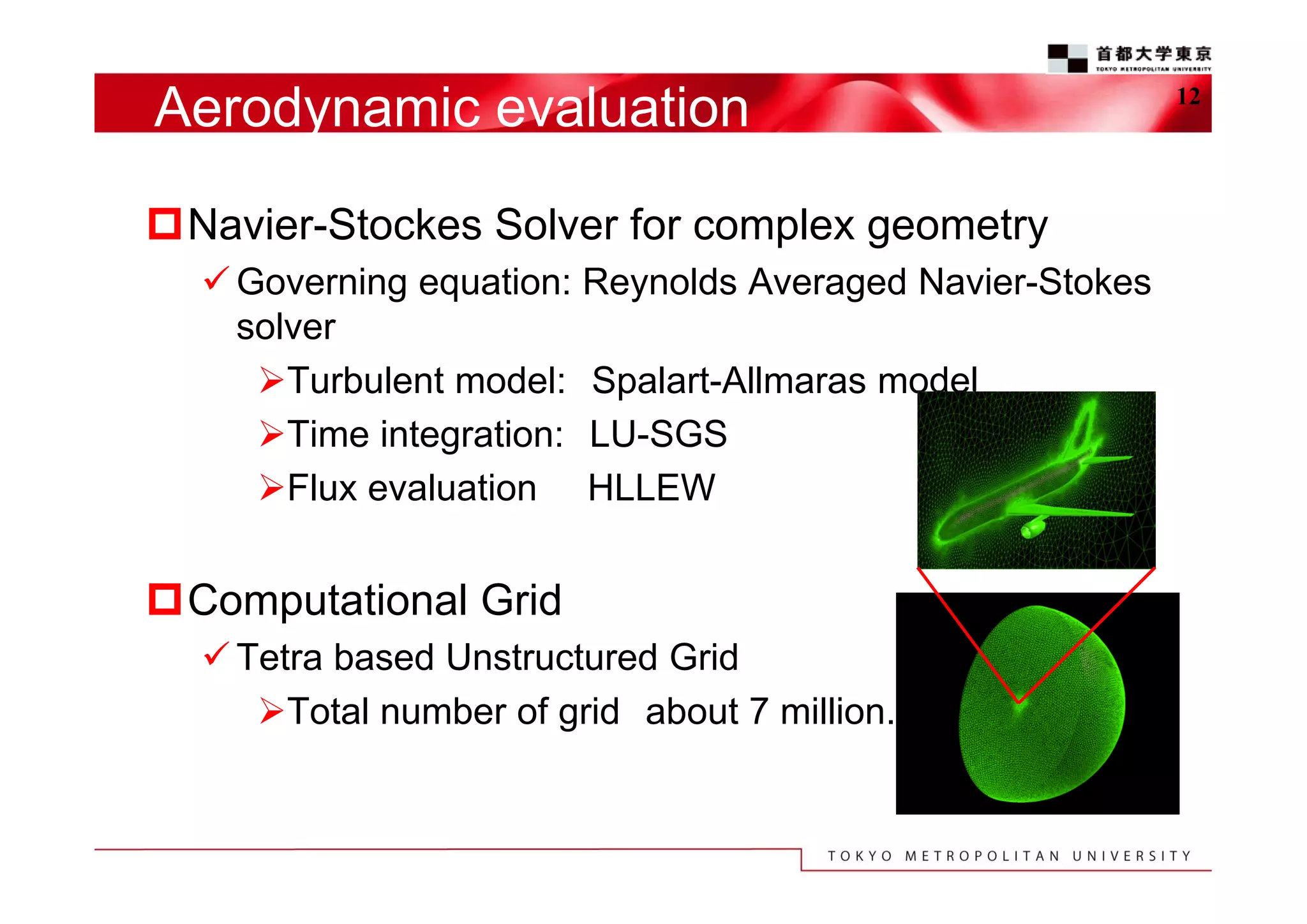

![Optimization Method(1/5)

7

Surrogate model:Kriging model

Interpolation based on sampling data

Standard error estimation (uncertainty)

y (xi ) (xi )

global model

localized deviation

from the global model

EI(Expected Improvement)

The balance between optimality and uncertainty

EI maximum point has possibility to improve the model.

Improvement at a point x is

I=max(fmin-Y,0)

Expected improvement E[I(x))]=E[max(fmin-Y,0)]

To calculate EI,

Jones, D. R., “Efficient Global

Optimization of Expensive BlackBox Functions,” J. Glob. Opt., Vol.

13, pp.455-492 1998.](https://image.slidesharecdn.com/131009ms6beurogen2013-131103224549-phpapp01/75/Efficient-Design-Exploration-for-Civil-Aircraft-Using-a-Kriging-Based-Genetic-Algorithm-7-2048.jpg)