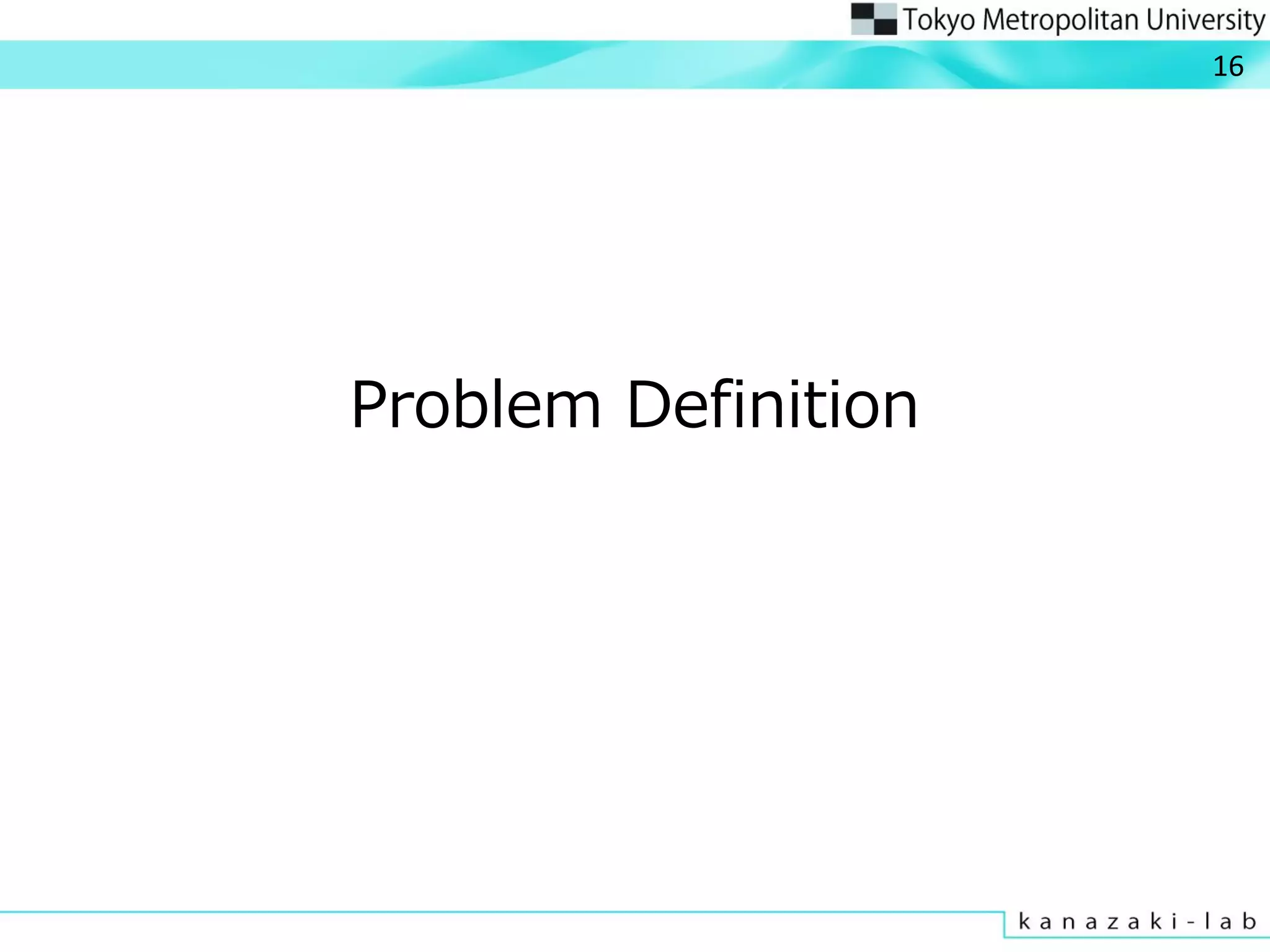

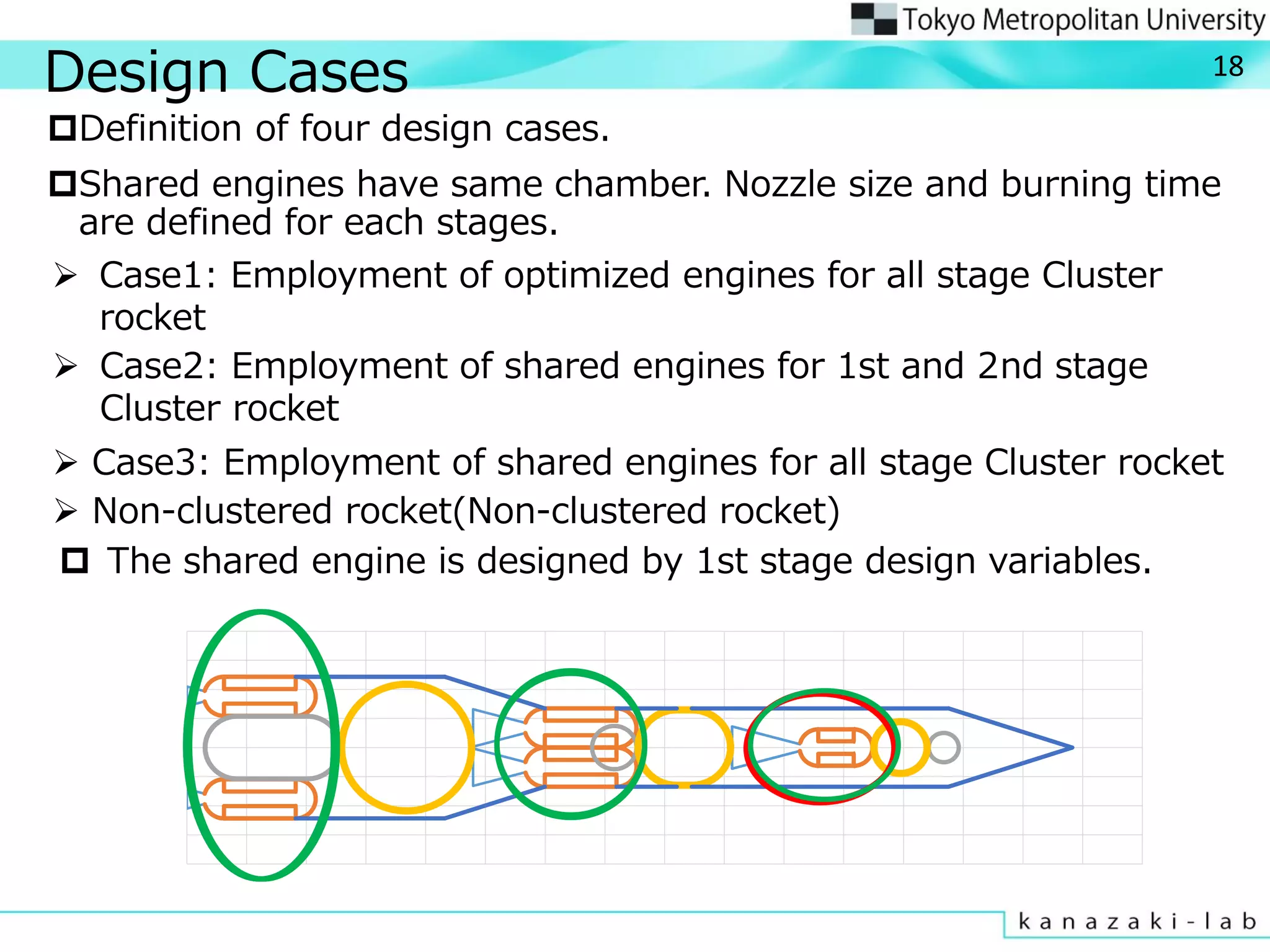

This document summarizes research on the design optimization of a launch vehicle concept using a clustered hybrid rocket engine for future space transportation. The researchers developed a design methodology for a launch vehicle with clustered hybrid rocket engines and investigated combinations of unit engines. Their objectives were to maximize payload to gross weight ratio and minimize gross weight. They defined four design cases and used multi-objective genetic algorithms and data visualization techniques to optimize the design variables. The results showed that a design with optimized engines for each stage performed best by avoiding excess unburnt fuel from shared engines across stages. Future work could further reduce unburnt fuel and improve payload ratio.

![Background

Advantage of hybrid

rocket engine(HRE)

Higher safety

Lower cost

Lower environmental

impact

Hybrid rocket has possibility

to be next generation

efficient launch vehicle.

Space ship two※1

※1,VirginGalactic http://www.virgingalactic.com/

※2, [1] Y. Kitagawa, K. Kitagawa, M. Nakamiya, M. Kanazaki, T.

Shimada, T JSASS, 55(2012), R4

3

Our previous research※2

Development of multi-

disciplinary design methodology

Optimization for single stage and

three stage launch vehicle](https://image.slidesharecdn.com/141007icfdver6-150616061126-lva1-app6891/75/ICFD2014-3-2048.jpg)

![Fuel Design

Regression rate rport is calculated by

n

tport Gatr ][)( )(0

8

.

.

Radius of fuel is calculated by rport and tb

(tb is design variables) .

G0(t) Oxidizer mass flux

a Fixed number decided by kind of fuel

n

β Simulating fuel circling

.](https://image.slidesharecdn.com/141007icfdver6-150616061126-lva1-app6891/75/ICFD2014-8-2048.jpg)

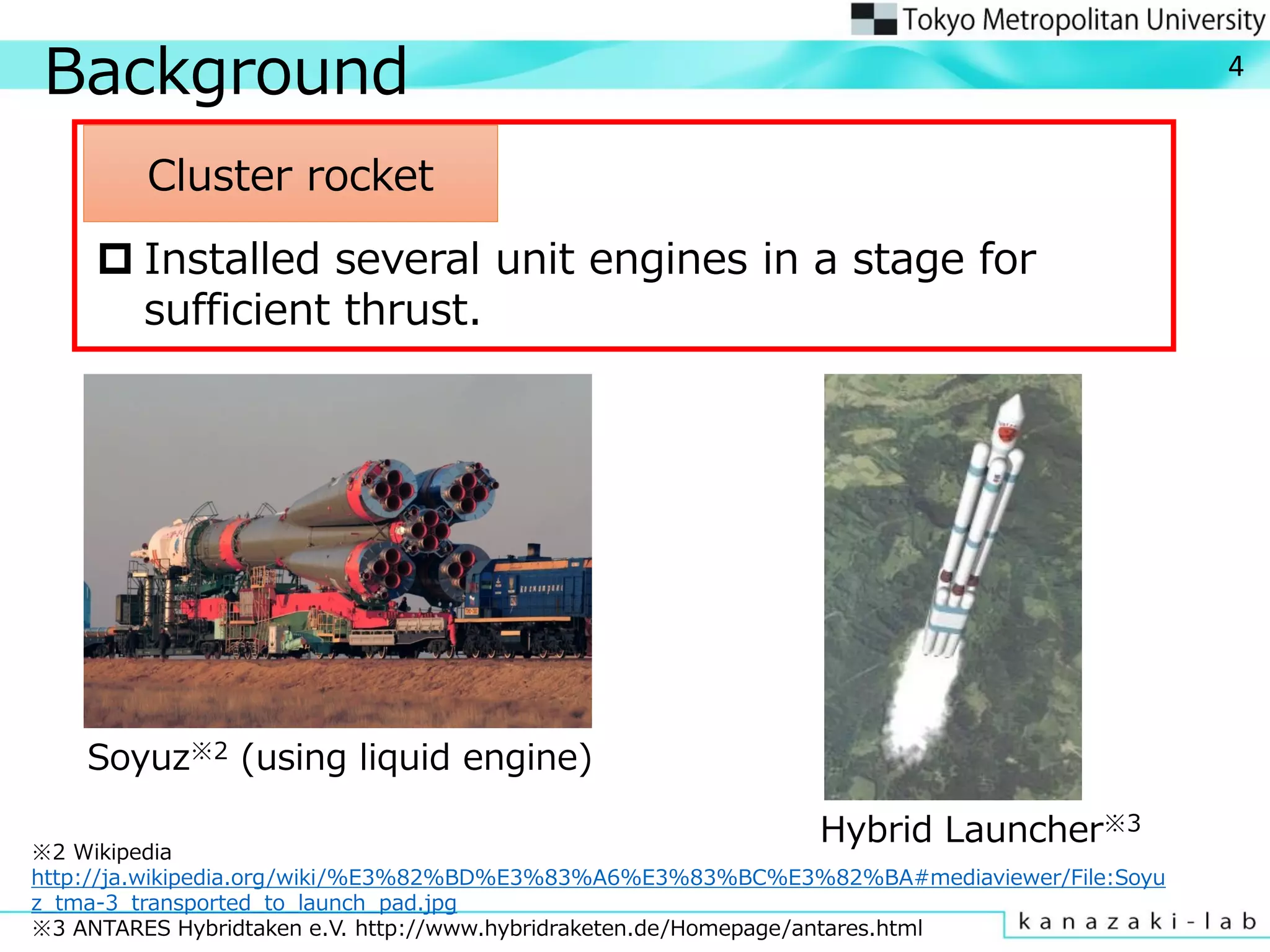

![Cluster Rocket Design Method

Evaluation of rocket radius

Radius of 2nd and 3rd stage exterior wall is equal to

radius of 2nd stage.

Radius of 1st stage is calculated independently.

11

Kind of fuel and oxidizer: Fuel…FT0070 Oxidizer…O2

FT0070

spec

Chemical formula Density[kg/m3] Index n Coefficient a

C35H72 910.0 0.3905 0.1561

n

tport Gatr ][)( )(0](https://image.slidesharecdn.com/141007icfdver6-150616061126-lva1-app6891/75/ICFD2014-11-2048.jpg)

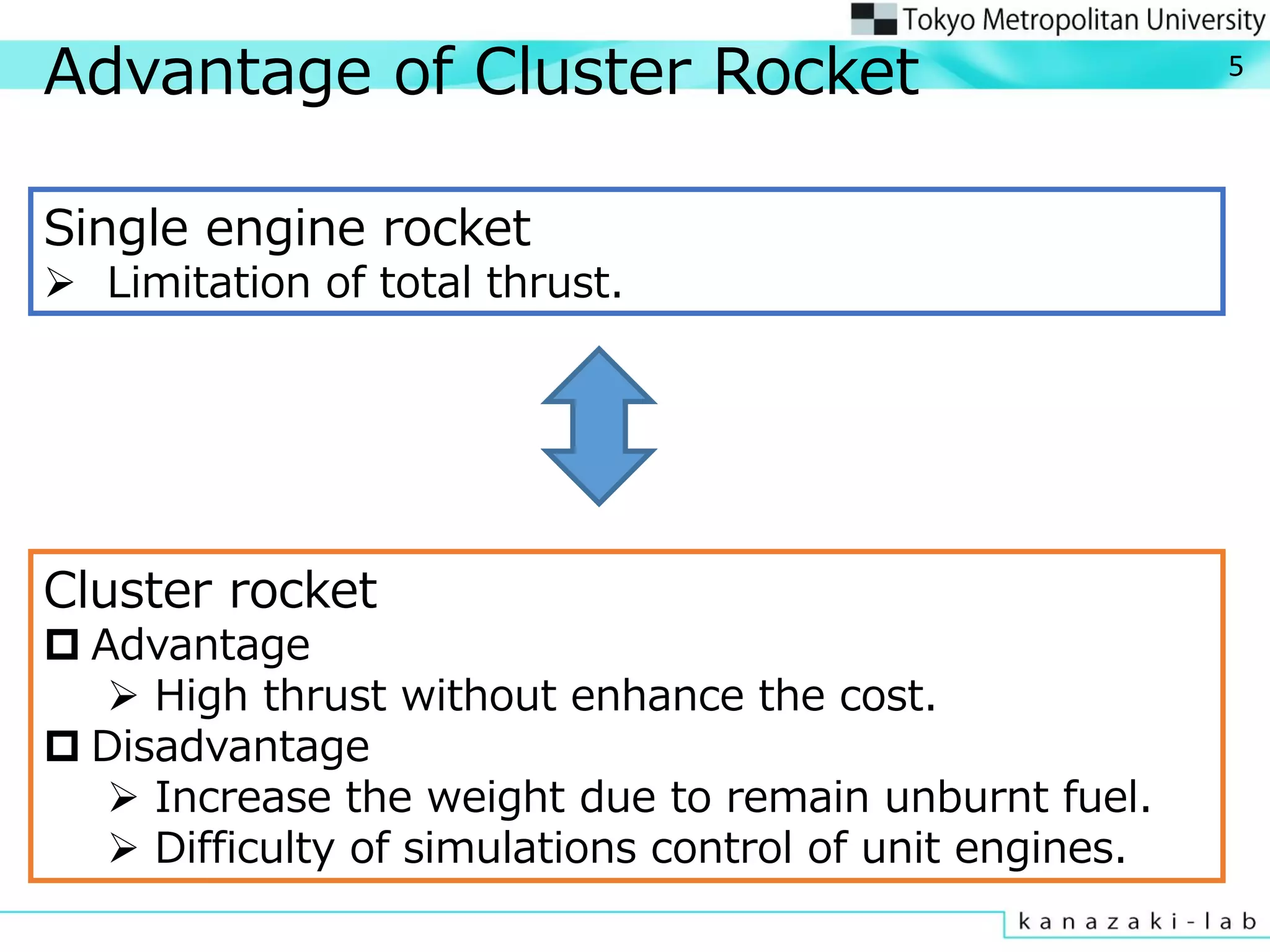

![Result of Design Optimization

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0 26.0 28.0 30.0

Mtot/Mpay[%]

Mtot[ton]

Case1 Case2 Case3 Non-clustered rocket

Trade off can be shown between two objective functions in each case.

Case1 show similar result as non-clustered case.

Case3 which employs same shared engine for each stage achieves

less than half performance compared with Case1.

Unburnt fuel is appeared when one engine design is shared in

two or three stages.

Optimum

Direction

20

Des1 Des0

Des2

Des3

Mpay=100[kg]](https://image.slidesharecdn.com/141007icfdver6-150616061126-lva1-app6891/75/ICFD2014-20-2048.jpg)

![Comparison from Pareto Solutions

Des1 has slender engines.

Des1 and Des2 use small engine in 3rd stage.

↔ Des3 uses largest engine in 3rd stage.

21

Length Radius

18.46[m] 0.60[m]

Length Radius

21.62[m] 0.59[m]

Length Radius(1st) Radius(2nd)

16.64[m] 1.42[m] 0.79[m]

Length Radius(1st) Radius(2nd)

14.83[m] 1.22[m] 0.68[m]

Des0

Des1

Des3

Des2](https://image.slidesharecdn.com/141007icfdver6-150616061126-lva1-app6891/75/ICFD2014-21-2048.jpg)

![Comparison of payload 100kg Rocket(Isp) 24

220

230

240

250

260

270

280

290

300

310

320

0 50 100 150 200 250 300 350 400 450

Isp[s]

Time[s]

While Des3 achieves the highest thrust in all stage, Isp of

3rd stage is the lowest.

Engines of Des3 are not only optimized for 3rd stage.

2nd stage of Des1 achieves the lowest Isp.

The efficiency is limited because the radius of 1st stage is

small.](https://image.slidesharecdn.com/141007icfdver6-150616061126-lva1-app6891/75/ICFD2014-24-2048.jpg)

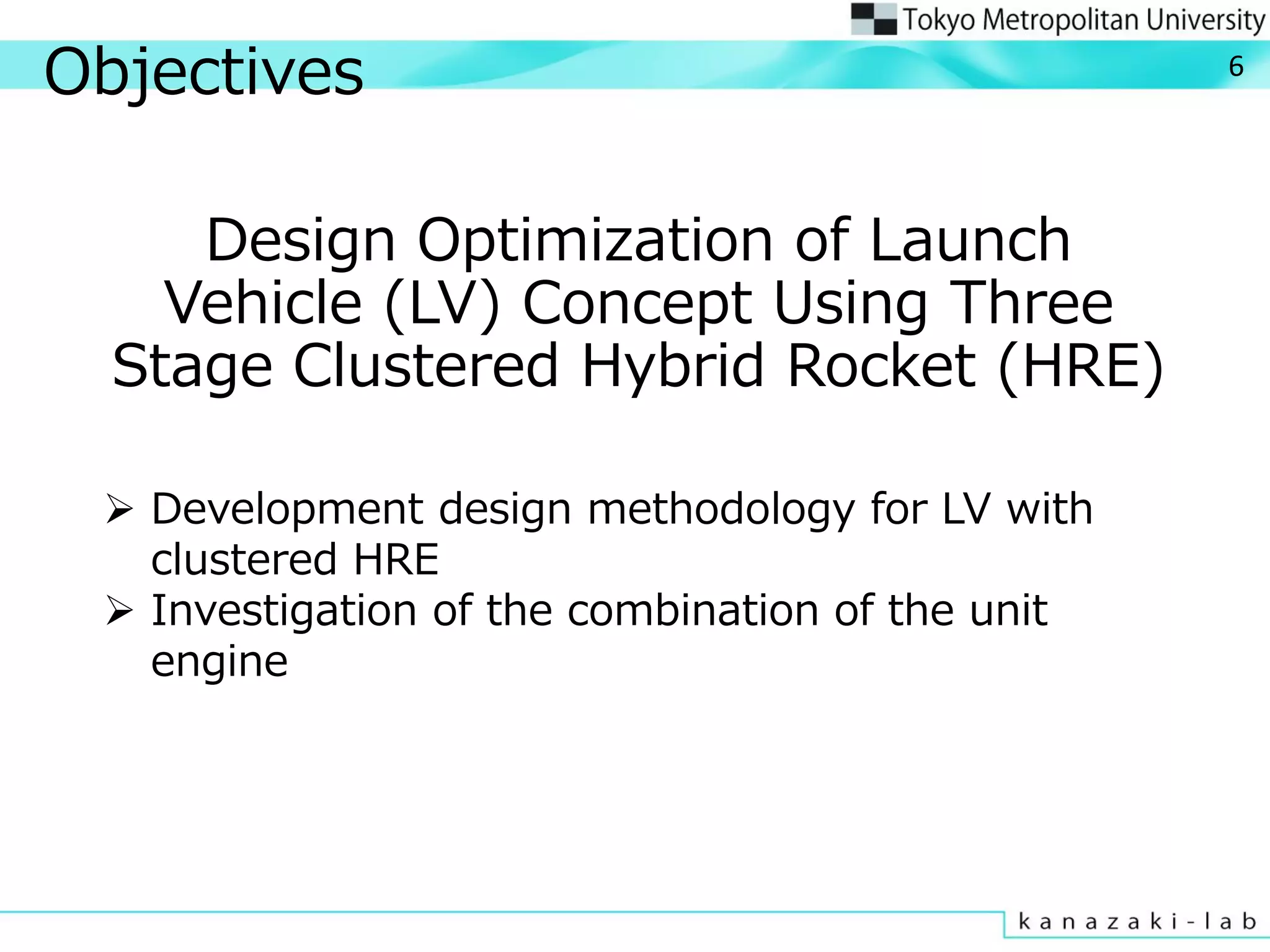

![Comparison of Payload 100kg Rocket(Numerical Value)

Mtot

[ton]

Mpay/Mtot

[%]

Des1 9.31 1.10

Des2 13.3 0.75

Des3 15.5 0.64

Payload ratio of Des3 is 0.5% less than Des1.

Because of unburnt fuel, total mass of Des3 become heavy.

Fuel Filling Ratio

1st stage 2nd stage 3rd stage

Des1 63[%] 80[%] 93[%]

Des2 86[%] 86[%] 88[%]

Des3 84[%] 84[%] 84[%]

Fuel filling ratio of Des1 is the smallest in 1st stage.

Des1 has slender engines to reduce aerodynamic drag.

Fuel filling ratio of Des2 and Des3 are high.

Because of the appearance of the unburnt fuel, payload

ratio of Des2 and 3 becomes lower than Des1.

It is also required to reduce unburnt fuel.

→(Future work)Addition of objective function objective function:

Minimize unburnt fuel

26

Fuel Filling Ratio=Area of fuel/Area of chamber](https://image.slidesharecdn.com/141007icfdver6-150616061126-lva1-app6891/75/ICFD2014-26-2048.jpg)