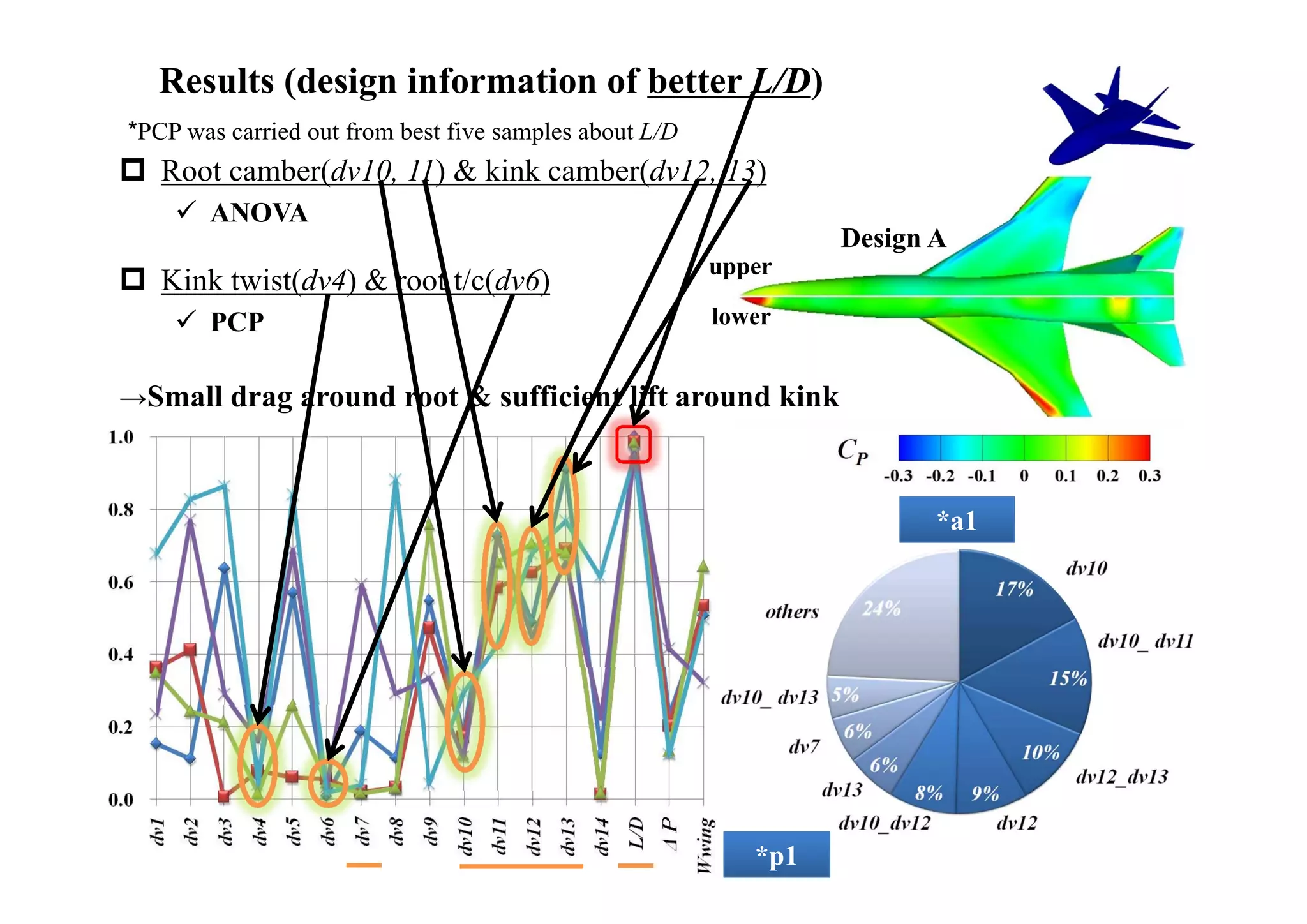

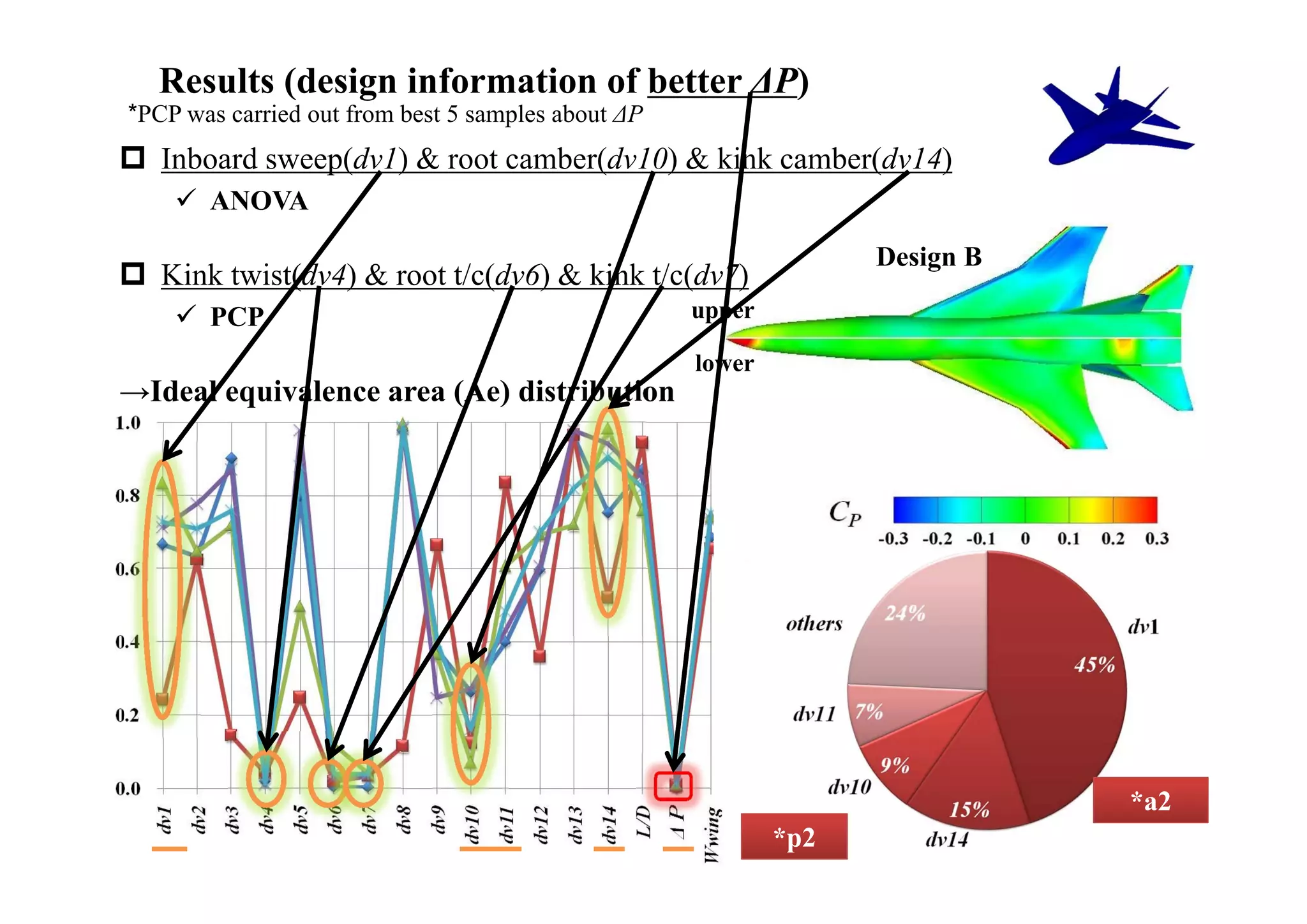

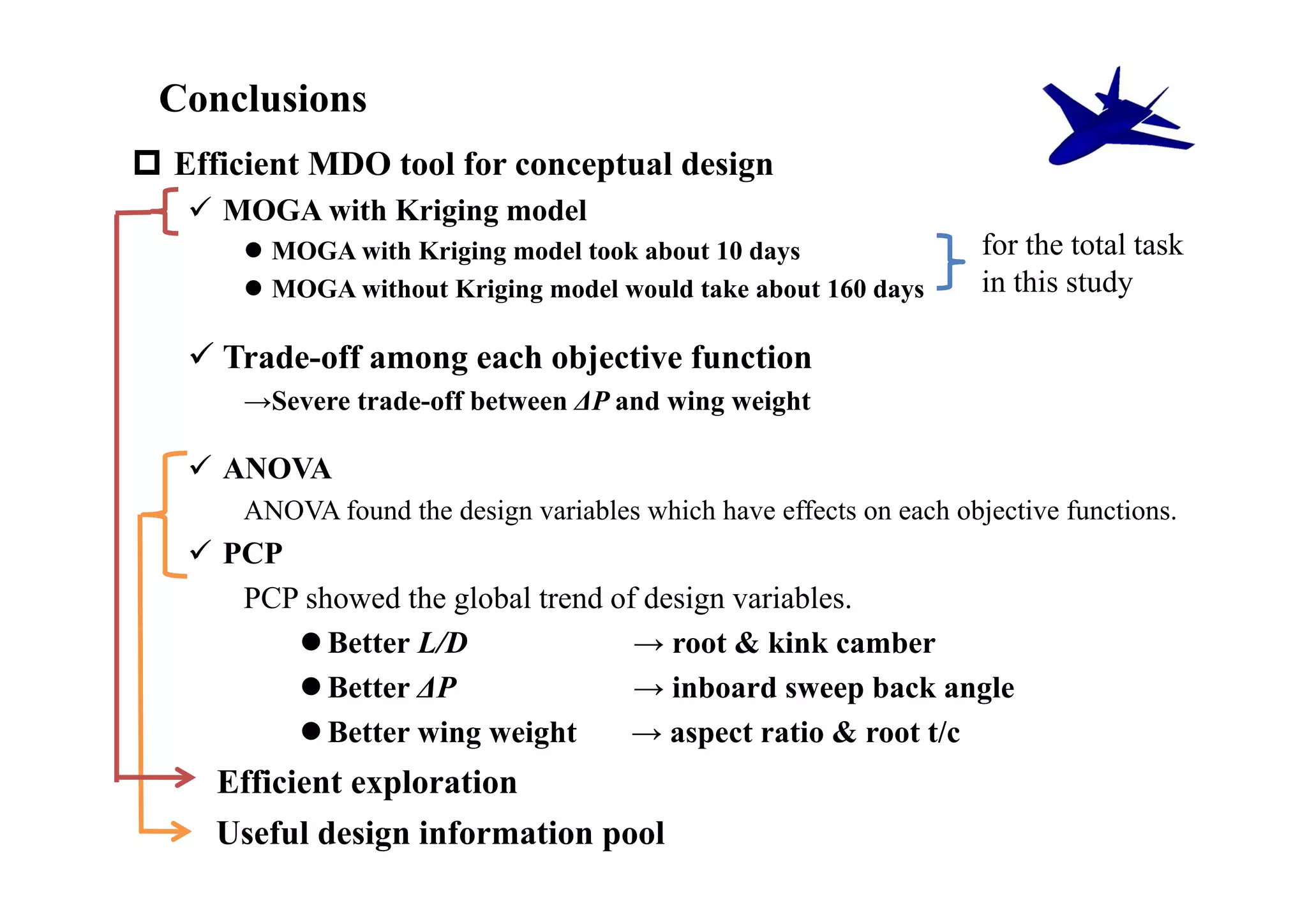

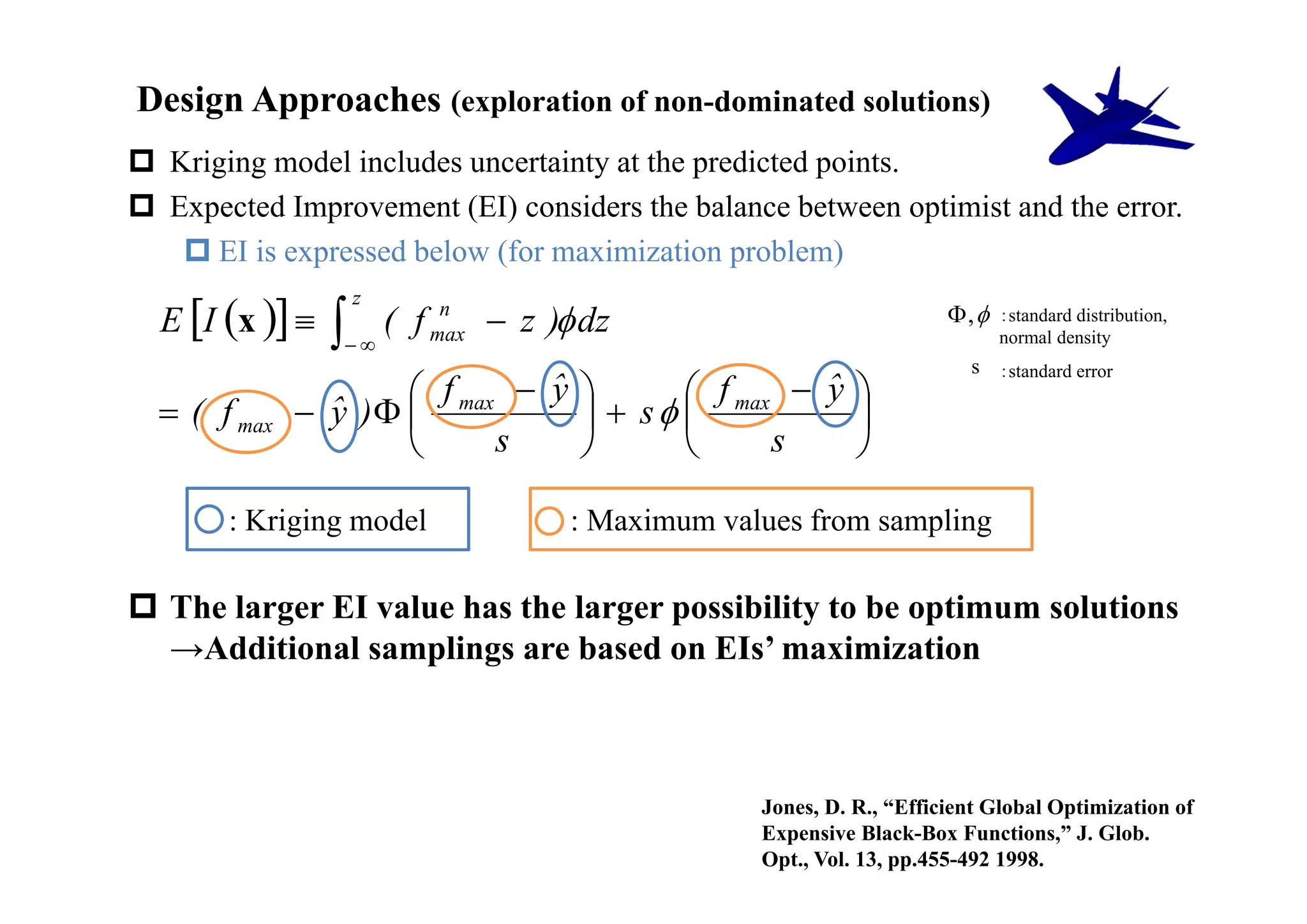

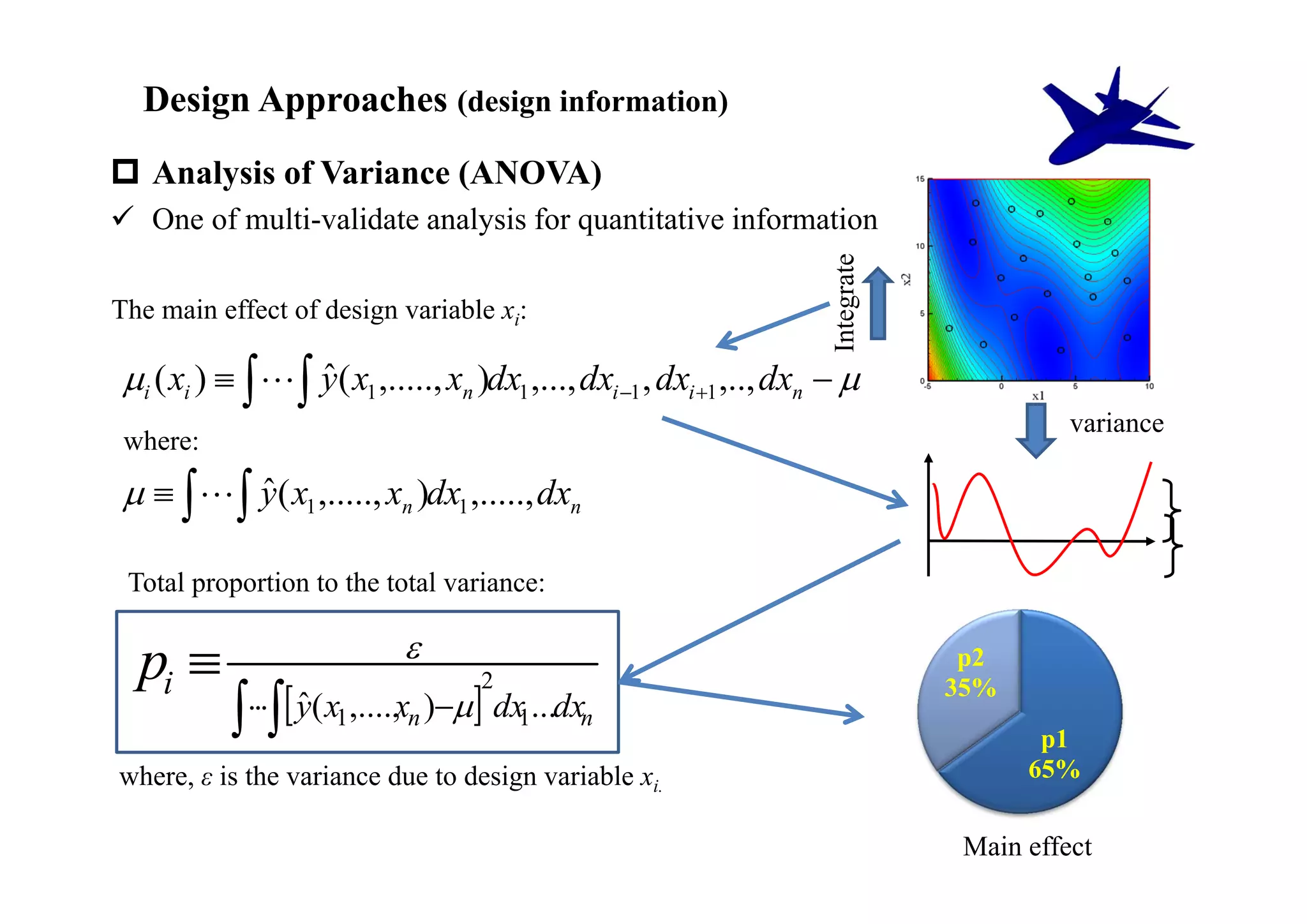

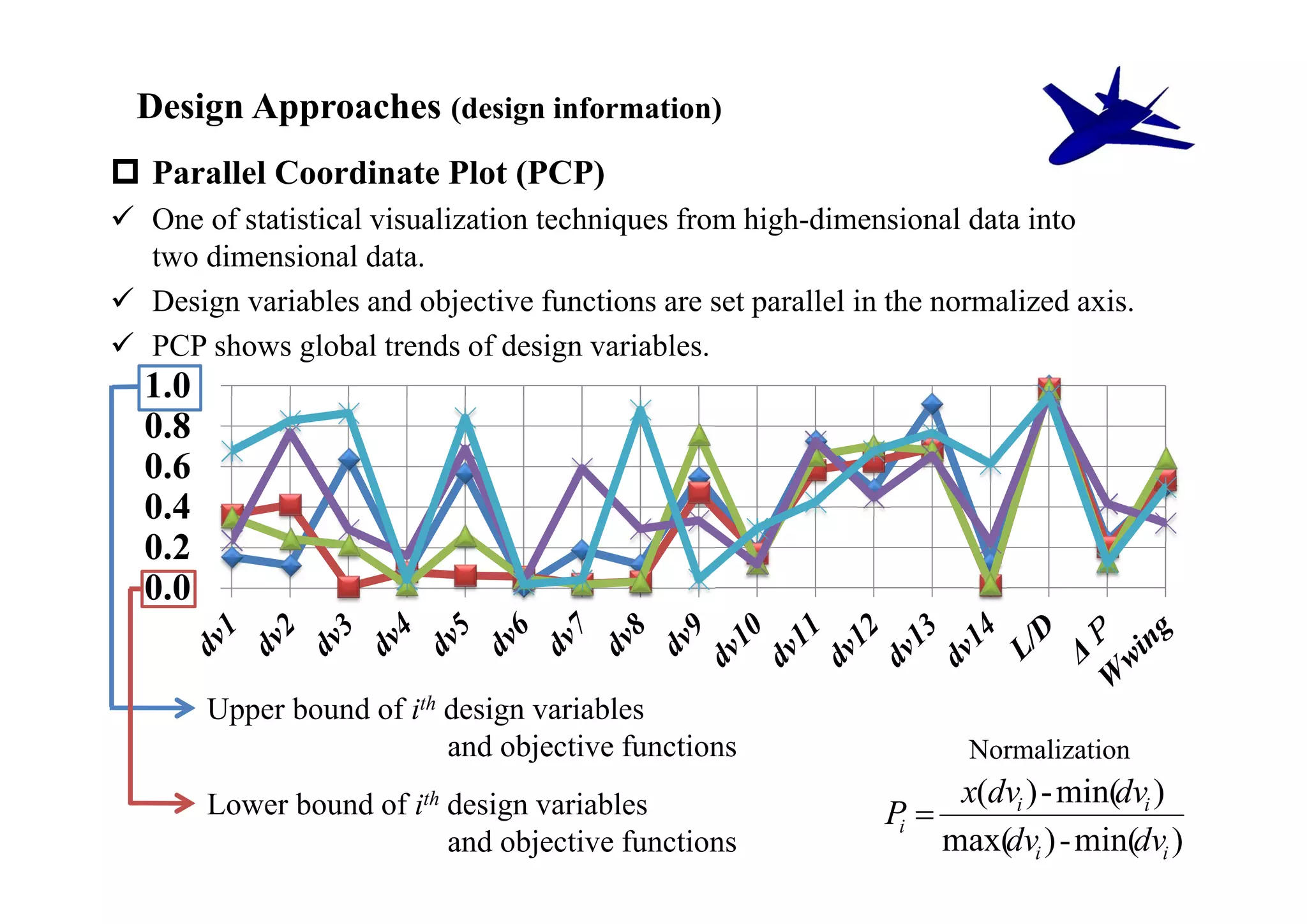

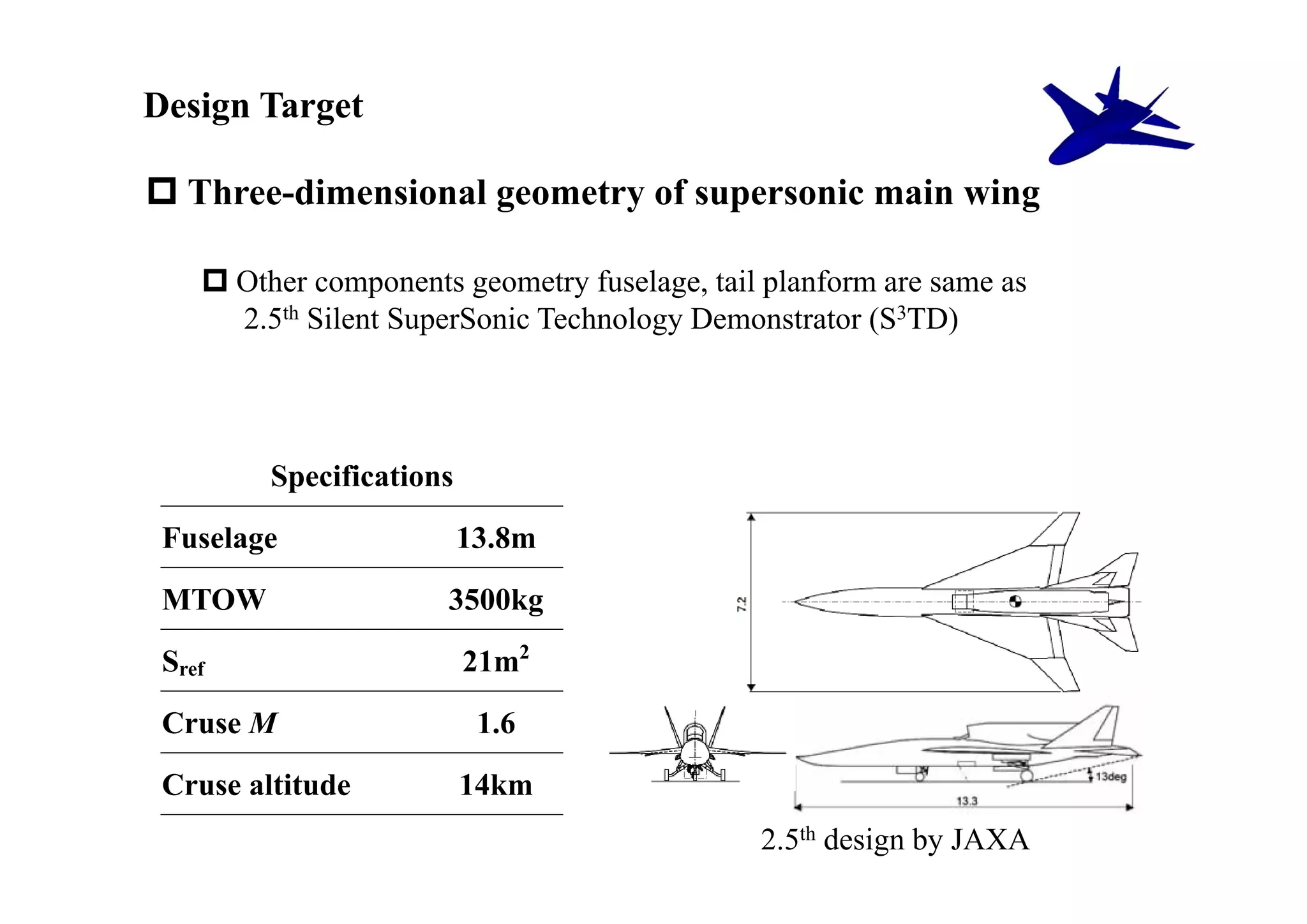

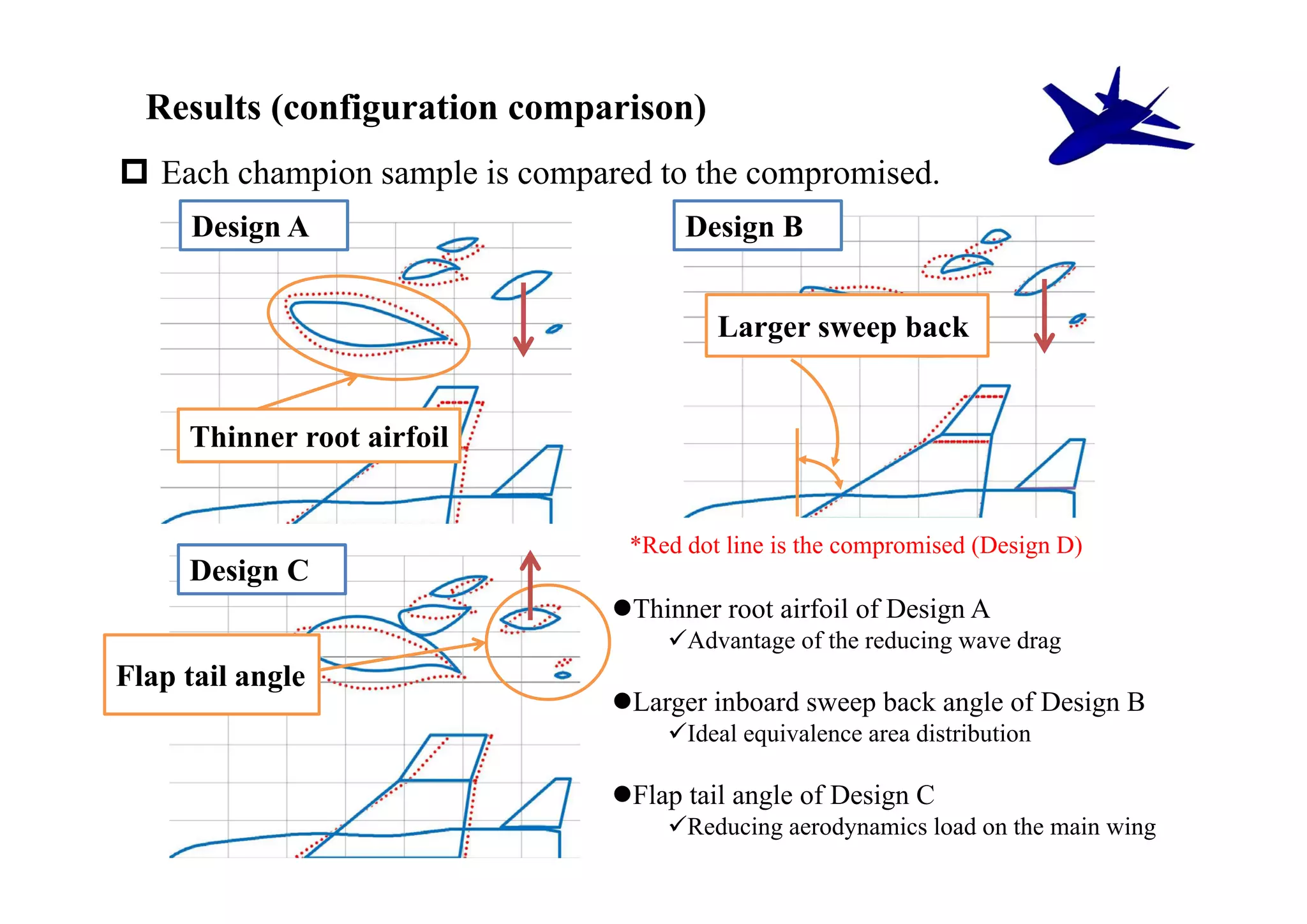

The document summarizes research on the multidisciplinary design optimization of supersonic transport wing concepts. The objectives were to develop an efficient MDO tool for conceptual design of SST wings using low-cost computational fluid dynamics and surrogate modeling. 107 design samples were evaluated for aerodynamic performance, sonic boom levels, and wing weight. 24 non-dominated solutions were identified, with the best designs having thinner root airfoils, larger inboard sweep angles, or modified tail angles compared to a baseline compromised design. Analysis of variance identified key design variables with the most influence on objectives.

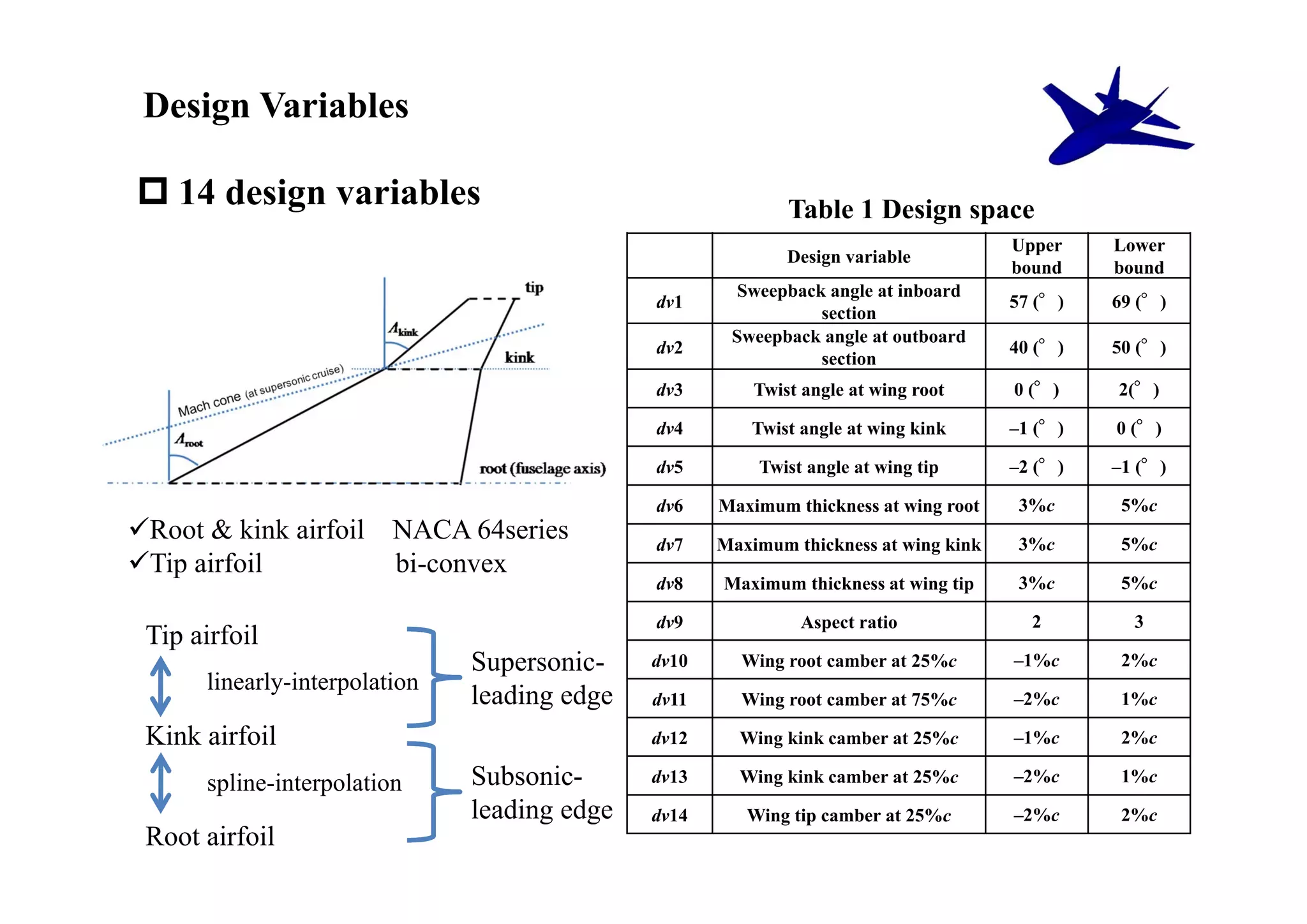

![Objective Functions

Three objective functions in this study

maximize L/ D

minimize ΔP (On boom carpet)

ΔP

minimize Wwing

subject to Design C L = 0.105

Time[ms]

maximize

K-means method

ˆ - L / Dmax

y ˆ - L / Dmax

y

• EIL / D = ( ˆ - L / Dmax )Φ(

y ) + sφ( ) Additional sampling points

s s

maximize

clusters

ΔP - ˆ y ΔP - ˆ y

EI1

• EIΔP = ( ΔP - y

min

ˆ )Φ( min ) + sφ( min )

s s

maximize

Wwingmin ˆy Wwingmin - ˆ

y EI2

• EIWwing = (Wwingmin - ˆ )Φ(

y ) + sφ( )

s s](https://image.slidesharecdn.com/icas2010setonaotofinal-121129200956-phpapp02/75/Multidisciplinary-Design-Optimization-of-Supersonic-Transport-Wing-Using-Surrogate-Model-16-2048.jpg)

![Evaluations of L/D and ΔP

CAPAS* developed in JAXA

Aerodynamic performance Sonic-boom intensity

Compressible potential equation Correction of shock wave

with panel method (PANAIR) by Whitham’s theory

2 2 2 PANAIR data

2 F ( x) CP

( M 1) 2

2

2

0 2

x y z

x

1 r F x

: Velocity potential

2 3

Thomas’s waveform parameter

method

M 2-1

pressure[psf]

1.4

Computational CP distributions r : propagation distance

geometry

Time[ms]

*CAPAS (CAD-based Automatic Panel Analysis System)](https://image.slidesharecdn.com/icas2010setonaotofinal-121129200956-phpapp02/75/Multidisciplinary-Design-Optimization-of-Supersonic-Transport-Wing-Using-Surrogate-Model-17-2048.jpg)

![Evaluation of wing weight

Inboard wing (multi-frame structure)

Aluminum material

Minimum thickness of skin & frame (0<thickness<20mm, every0.1mm)

Outboard wing (full-depth honeycomb sandwich structure)

Composite material

Stack sequence

Fiber angle θ ; [0/ θ/- θ/90] ns, θ=15, 30, 45, 60, 70deg

Number of laminations n n N 25

Solver is MSC NASTRAN 2005R (FEM model)

Strength requirements

Aluminum material:Mises stress < 200MPa at all FEM nodes

Composite material: Destruction criteria < 1 at all FEM nodes on each laminate

Computational conditions

Symmetrical maneuver +6G, Safety rate: 1.25 PANAIR data

Estimated load on the main wing

(symmetrical maneuver) × (safety rate) × (aerodynamics load)](https://image.slidesharecdn.com/icas2010setonaotofinal-121129200956-phpapp02/75/Multidisciplinary-Design-Optimization-of-Supersonic-Transport-Wing-Using-Surrogate-Model-18-2048.jpg)

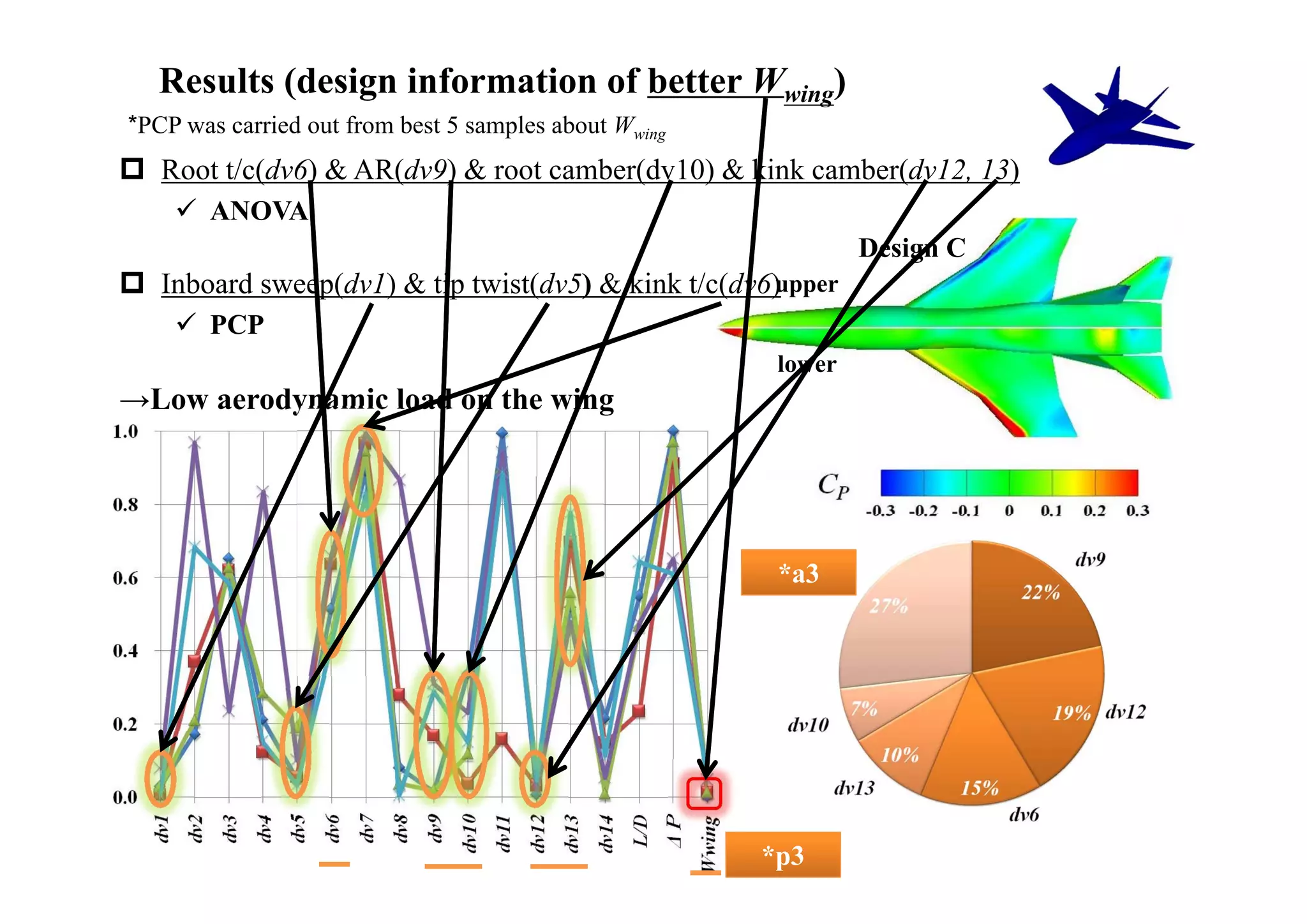

![Results (solution space about objective functions)

Wwing

24 non-dominated solutions from L/D ΔP[psf] AoA

[kg]

final data Design A 7.02 1.19 612 2.5

Most of additional samplings formed Design B 6.08 0.97 502 2.7

non-dominated solutions Design C 5.60 1.53 276 2.6

Design D 6.77 1.09 691 2.6

Design A (best L/D) Design B (best ΔP) Design C (best Wwing)

Design D (compromised)

Wwing[kg]

ΔP[psf]

Optimum direction

L/D ΔP[psf]](https://image.slidesharecdn.com/icas2010setonaotofinal-121129200956-phpapp02/75/Multidisciplinary-Design-Optimization-of-Supersonic-Transport-Wing-Using-Surrogate-Model-22-2048.jpg)

![Evaluation of wing weight evaluations

Inboard wing (multi-frame structure)

Aluminum material

Minimum thickness of skin & frame (0<thickness<20mm, every0.1mm)

Outboard wing (full-depth honeycomb sandwich structure)

Composite material

Stack sequence

Fiber angle θ ; [0/ θ/- θ/90] ns, θ=15, 30, 45, 60, 70deg

Number of laminations n n N 25

Solver is MSC NASTRAN 2005R (FEM model)

Strength requirements

Aluminum material:Mises stress < 200MPa at all FEM nodes

Composite material: Destruction criteria < 1 at all FEM nodes on each laminate

Computational conditions

Symmetrical maneuver +6G, Safety rate: 1.25 PANAIR data

Estimated load on the main wing

(symmetrical maneuver) × (safety rate) × (aerodynamics load)](https://image.slidesharecdn.com/icas2010setonaotofinal-121129200956-phpapp02/75/Multidisciplinary-Design-Optimization-of-Supersonic-Transport-Wing-Using-Surrogate-Model-24-2048.jpg)

![Results (waveform on the ground)

Each champion sample is compared to the compromised.

*Red dot line is the compromised (Design D)

Less different

Design A

among Design A, B, and D

Large different

between Design C and D

L/D ΔP[psf] Wwing[kg]

Design B

Design A 7.02 1.19 612

Design B 6.08 0.97 502

Design C 5.60 1.53 276

Design D 6.77 1.09 691

Design C

Severe trade-off

between ΔP & Wwing](https://image.slidesharecdn.com/icas2010setonaotofinal-121129200956-phpapp02/75/Multidisciplinary-Design-Optimization-of-Supersonic-Transport-Wing-Using-Surrogate-Model-25-2048.jpg)