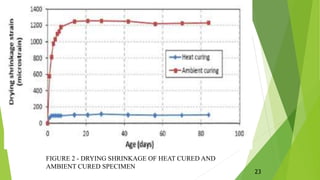

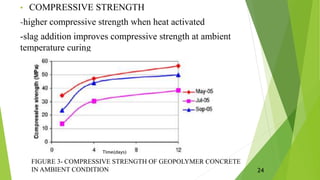

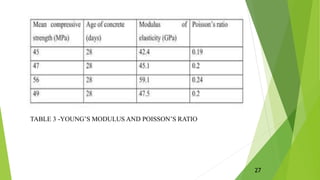

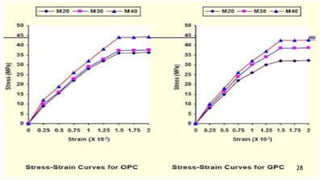

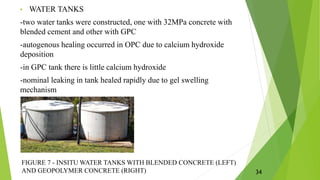

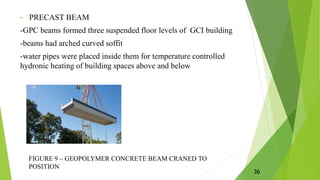

Geopolymer concrete is an innovative and eco-friendly alternative to traditional cement concrete, utilizing materials like fly ash and alkali solutions instead of cement, thereby reducing carbon dioxide emissions. It exhibits superior properties such as high compressive strength, low creep, and durability, making it suitable for various applications including precast products, pavements, and water tanks. While there are advantages like chemical resistance and fireproofing, challenges such as high costs and handling issues remain, necessitating further research and wider acceptance in the construction industry.