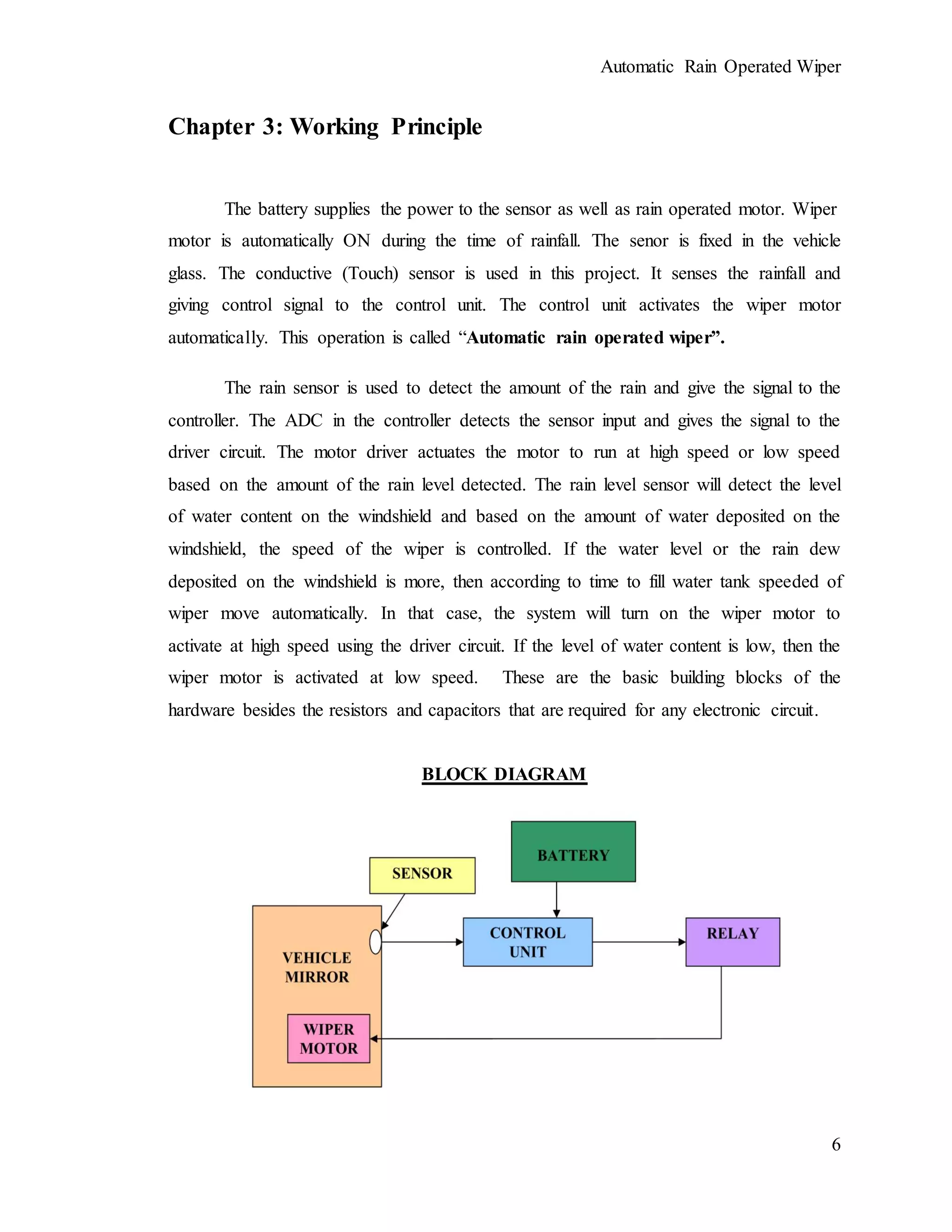

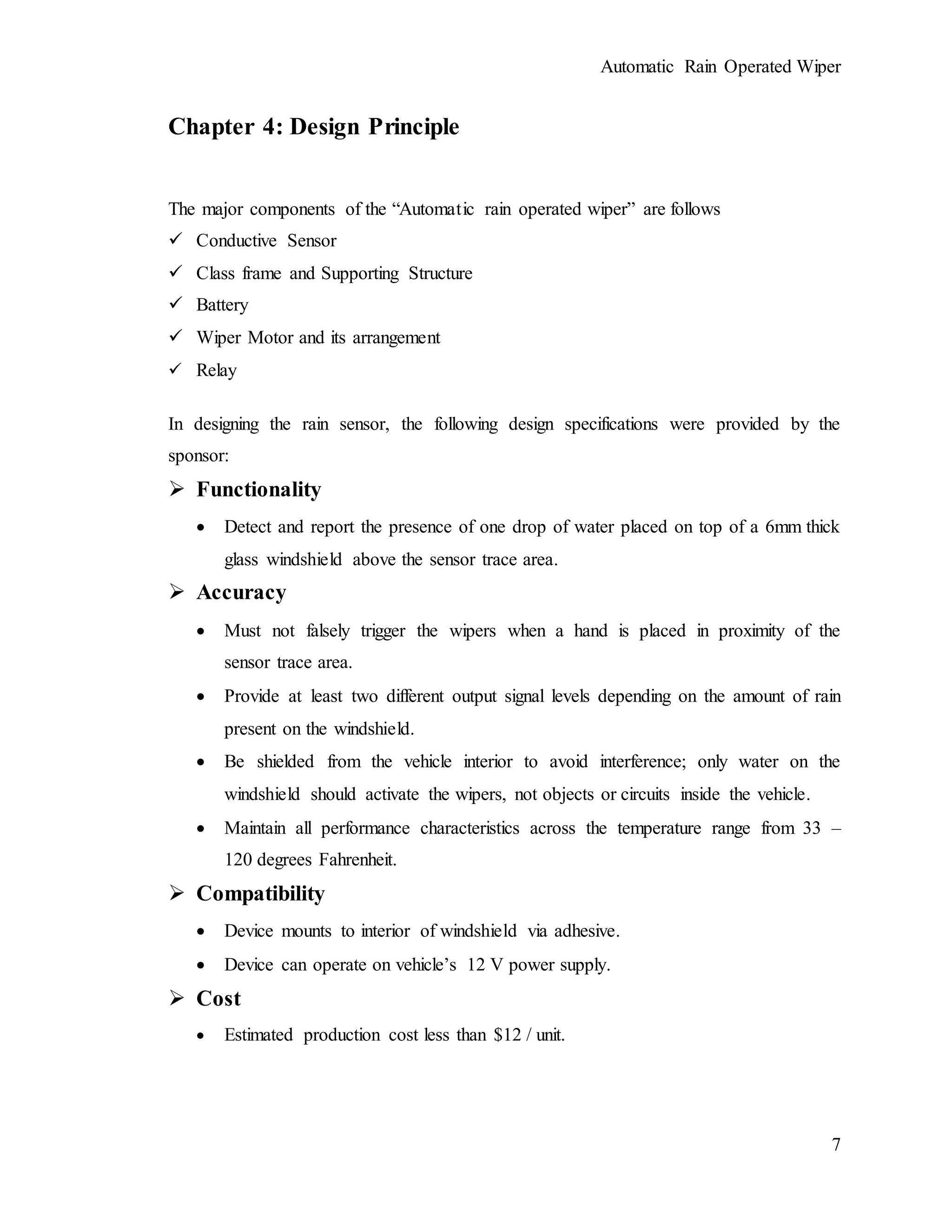

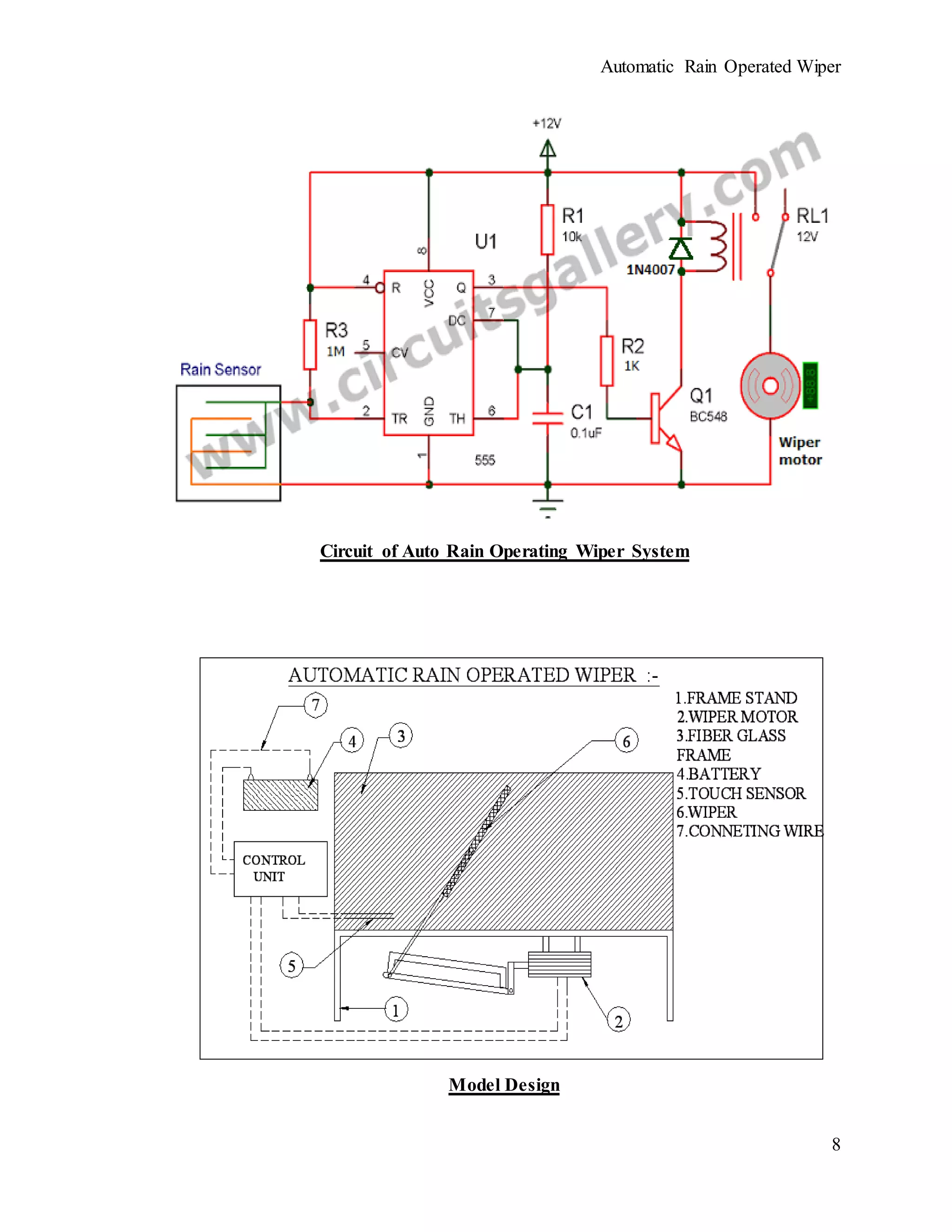

The document discusses the design and benefits of an automatic rain-operated wiper system that enhances driving safety by minimizing distractions. This system utilizes advanced sensors to detect rainfall and adjusts wiper speed based on the amount of water on the windshield, significantly improving driver convenience. It compares traditional optical sensors with the new capacitive sensor technology which offers greater accuracy, lower cost, and reduced false positives.

![Automatic Rain Operated Wiper

11

Chapter 9: References

[1] Abhishek Shukla, Rohan Dwivedi ”Design and Implementation of Vision System Aid

in Windscreen Assembly” International Journal of Computer Applications (0975 –

8887)Volume 7– No.12, October 2010

[2] Joonwoo Son · Seon Bong Lee, Man Ho Kim · Suk Lee*, Kyung Chang Lee**”

Intelligent Rain Sensing and Fuzzy Wiper Control Algorithmfor Vision-based Smart

Windshield Wiper System”

[3] Hideki Kajioka,Keiji Fujimura,Yasuhiro Fujita”Automatic wiper comtroller using

optical sensor”

[4] Wong Sai Hoong & Gilbert Thio”Design of A Moisture Controller For Wiper” Paper

reach report JASA |July 2006

[5] Shinichi KATO* Toshinori YAGI* “Development of a Rain-Light Sensor”Technical

Review 2008

[6] Bosch, "CAN Specification 2.0", in Robert Bosch GmbH, 1991.

[7] Working system of windshield wiperhttp://auto.howstuffworks.com/wiper.htm

[8] History of Windshield wiper.http://www.answers.com/topic/windscreen-wiper- 1.

[9] Lee, Mark. Cypress Semiconductor Corp. "The Art of Capacitive Touch

Sensing."PlanetAnalog.com. 06 Mar. 2006. Web. 18 Feb. 2010.

<http://www.planetanalog.com/features/showArticle.jhtml?articleID=181401898>.

[10] Brychta, Michael. "Measure Capacitive Sensors With A Sigma-Delta

Modulator."Electronicdesign.com. 28 Apr. 2005. Web. 15 Feb. 2010.

<http://electronicdesign.com/article/analog-and-mixedsignal/measure-capacitive-sensors-

with-a-sigma-delta-modu.aspx>.](https://image.slidesharecdn.com/miniproject-rainsensingwiper-170310151726/75/Mini-project-rain-sensing-wiper-11-2048.jpg)