1. The document discusses the ingredients and components used in the moulding process for casting metals. It describes the key materials like sand, clay, moisture and their properties.

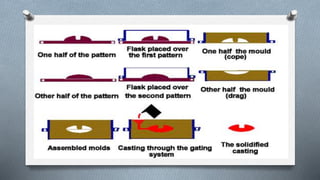

2. The moulding process involves making a cavity in sand using a pattern, incorporating the pattern in a gating system, removing the pattern, pouring molten metal, allowing it to cool, and removing the casting.

3. The advantages of the moulding process are its reusability, good dimensional accuracy, and high production rates compared to other casting methods. Typical tolerances and surface finishes are provided.