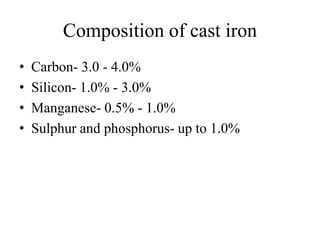

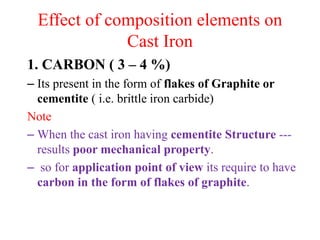

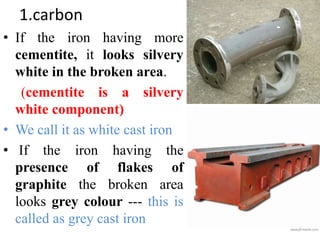

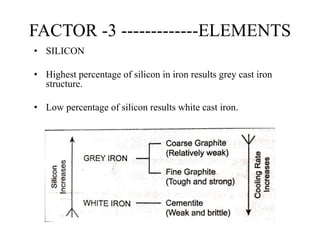

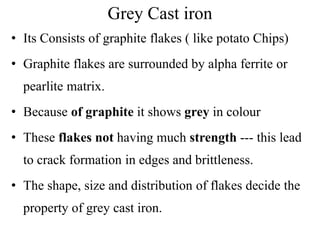

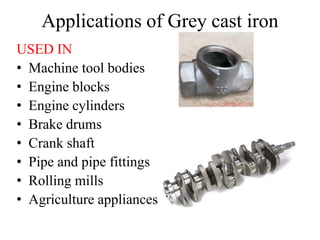

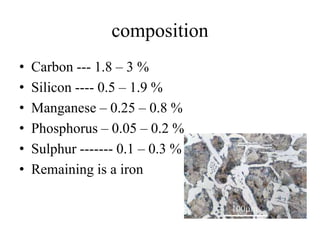

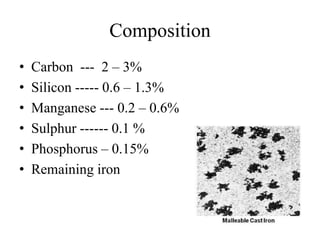

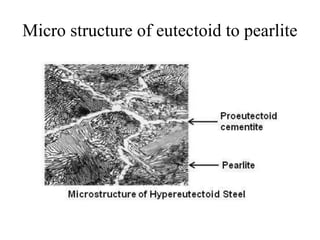

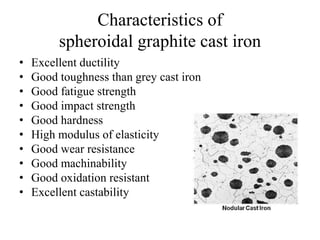

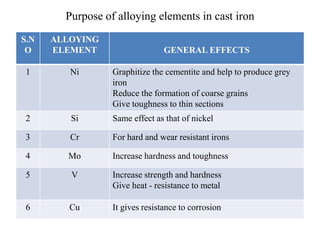

This document discusses different types of cast irons and their properties. It begins by describing the composition of cast iron which contains more than 2% carbon along with alloying elements like silicon, sulfur, manganese, and phosphorus. The main types discussed are grey cast iron, which is the most widely used due to its low cost; white cast iron, which is very hard and brittle; malleable cast iron, which is made by heat treating white cast iron to improve ductility; and spheroidal graphite cast iron, which has improved ductility from nodular graphite formation. The document also covers how alloying elements and heat treatments can impact the microstructure and properties of cast irons.