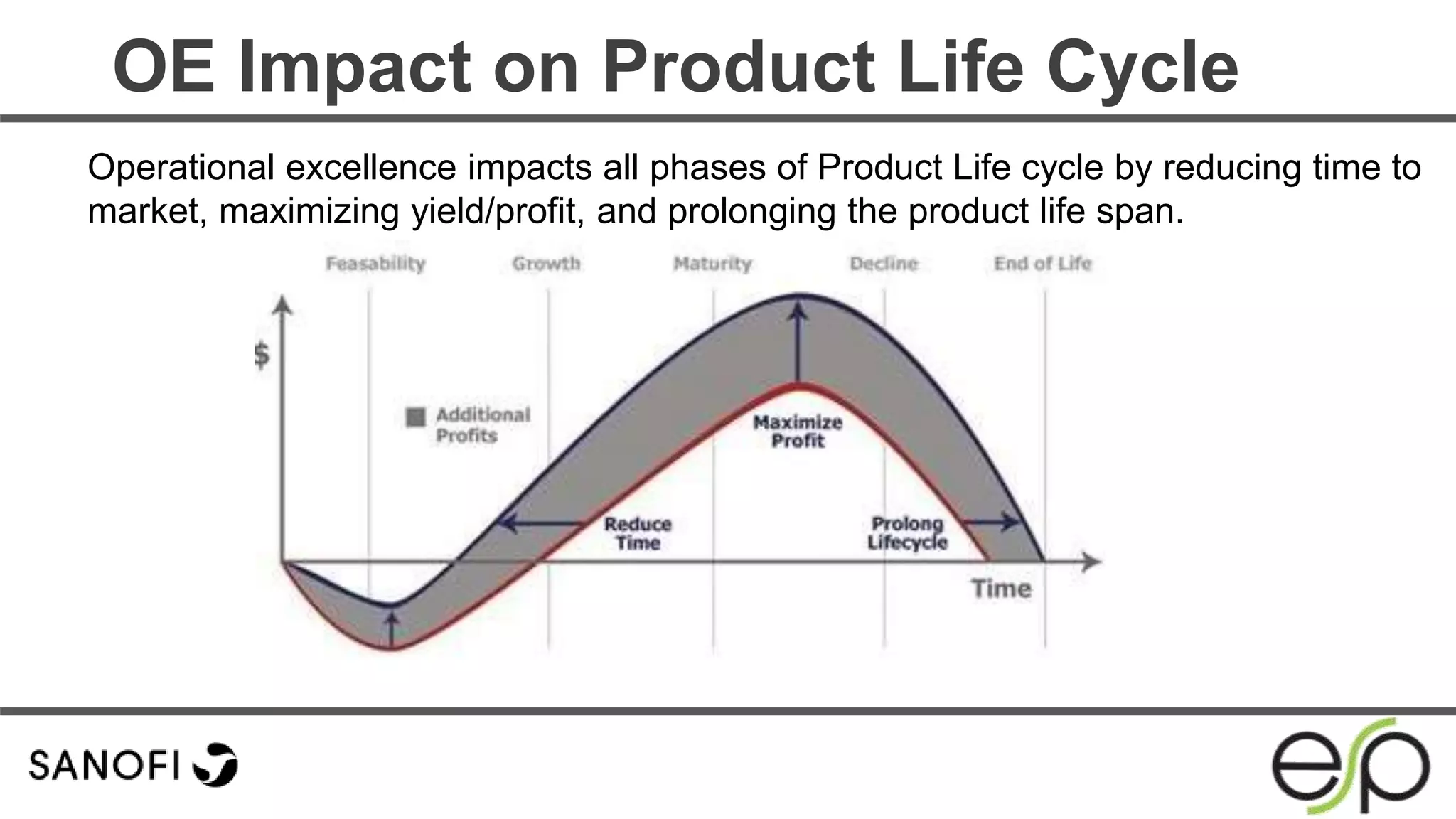

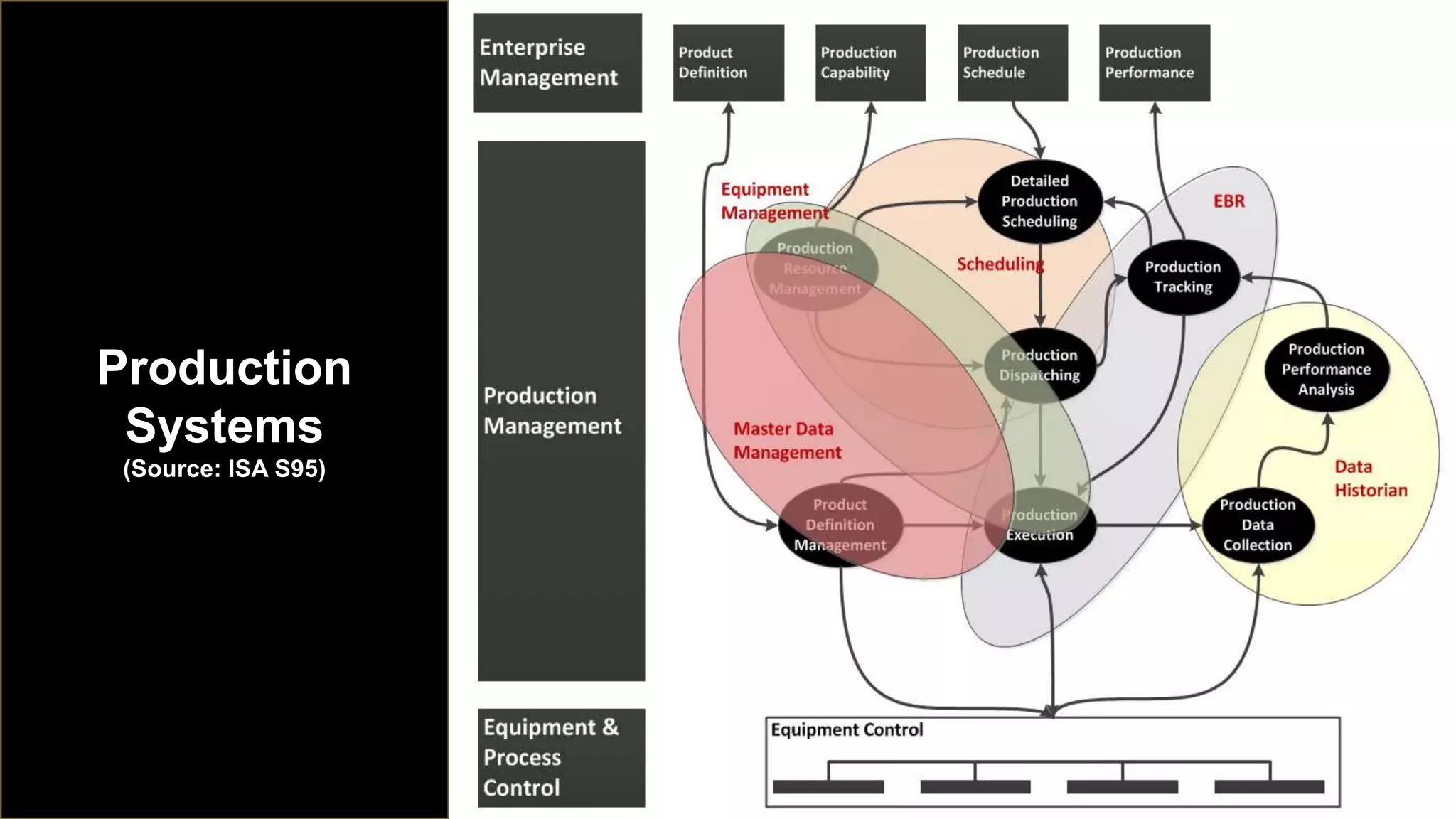

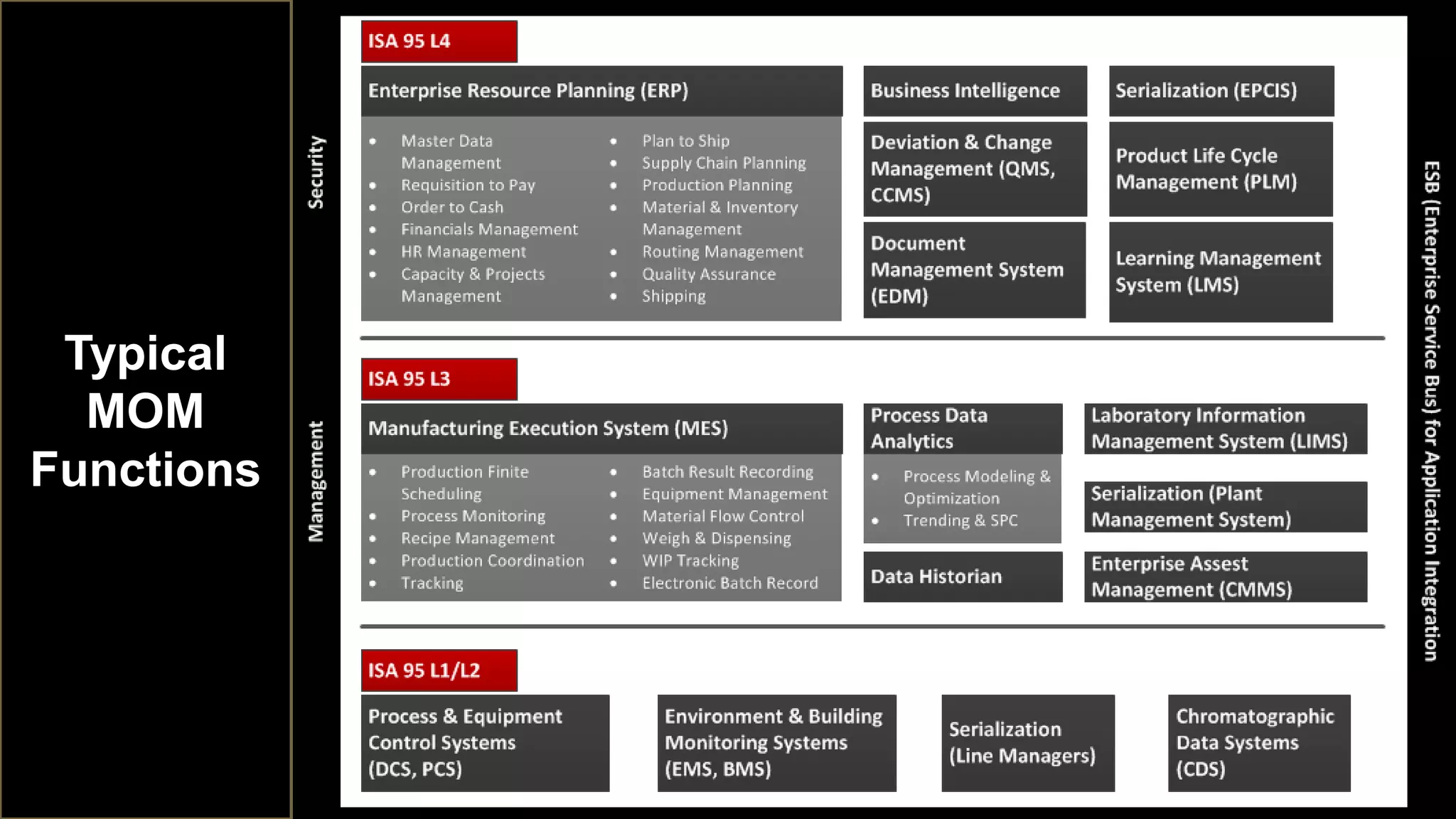

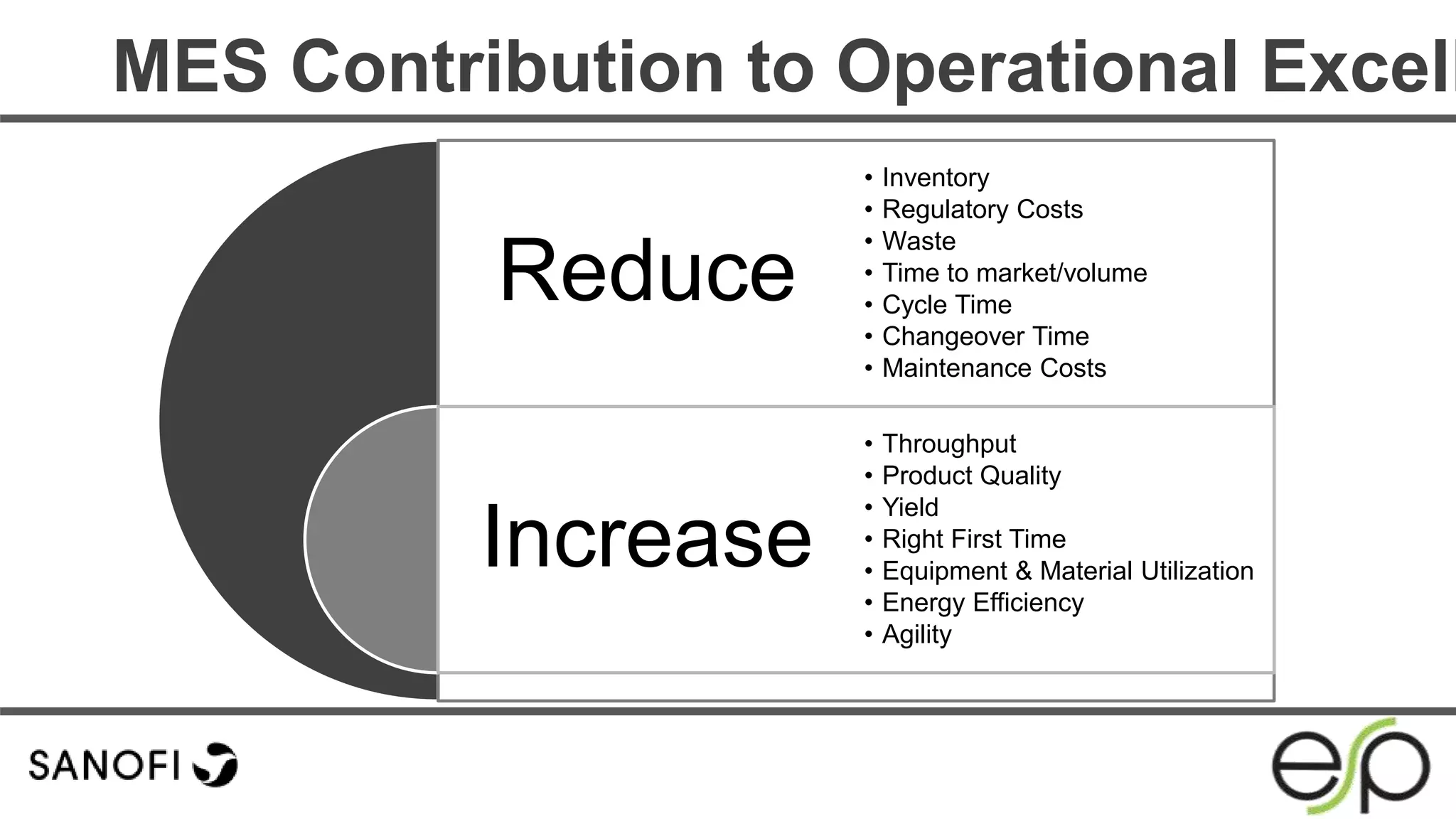

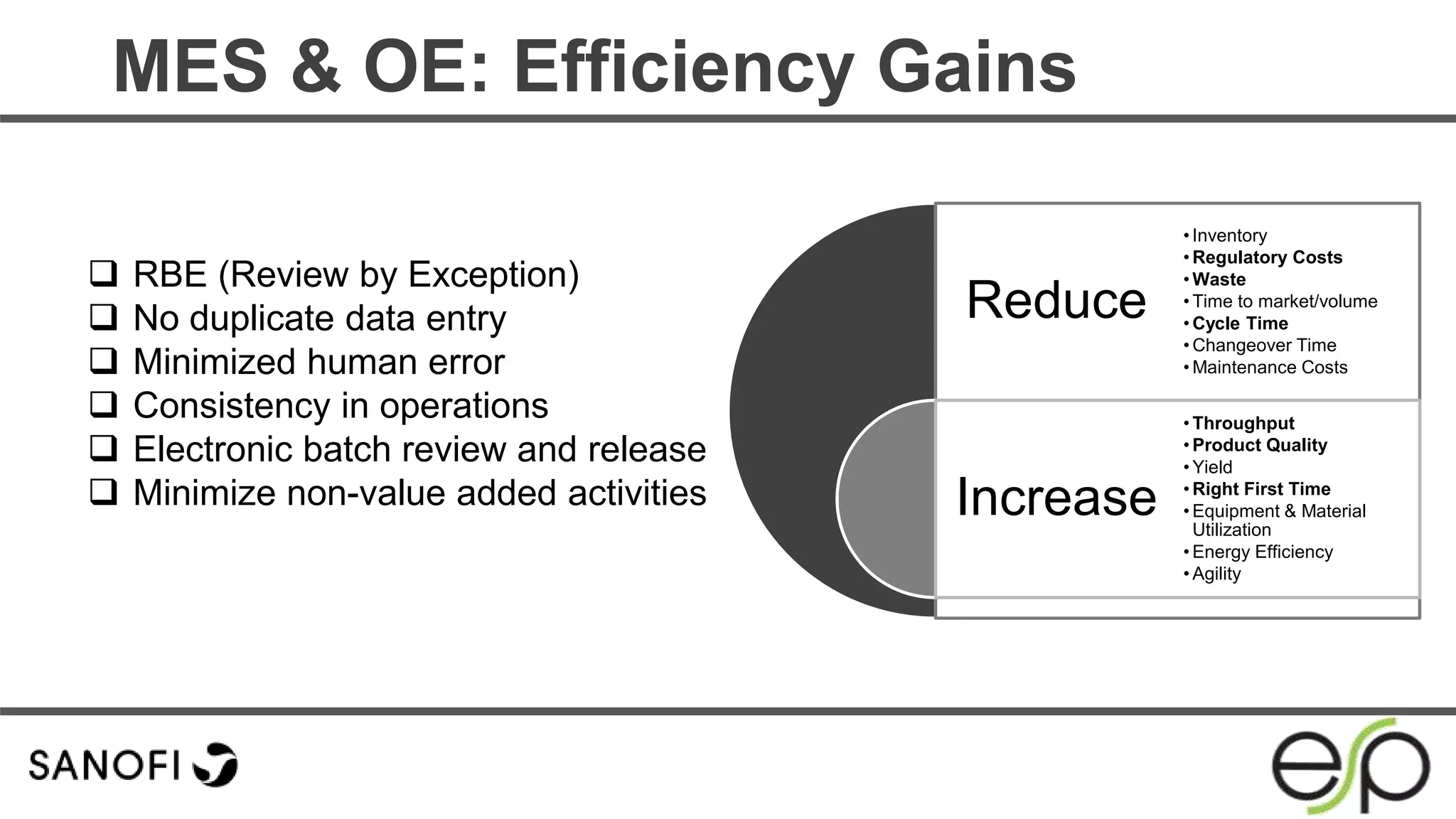

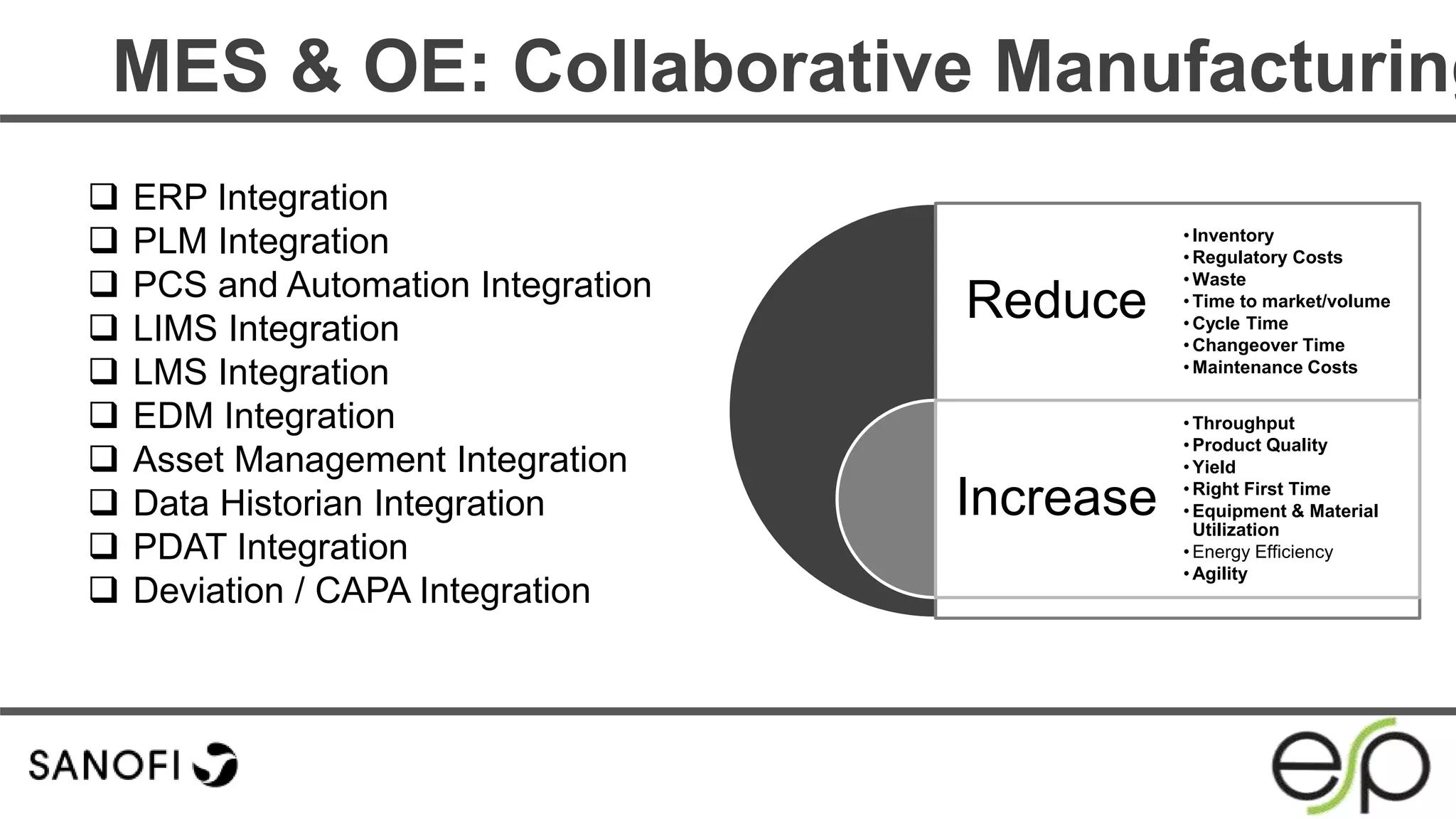

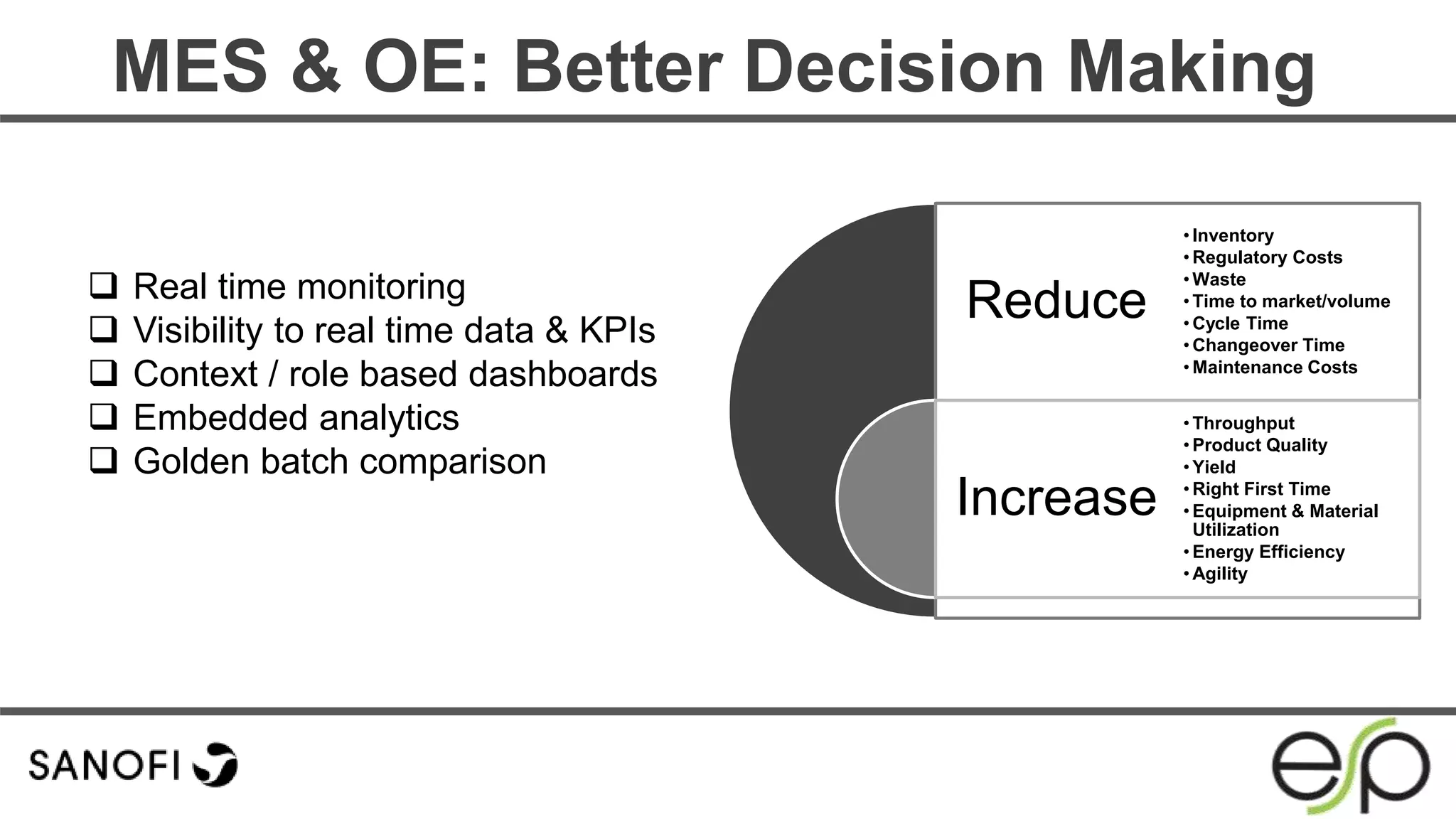

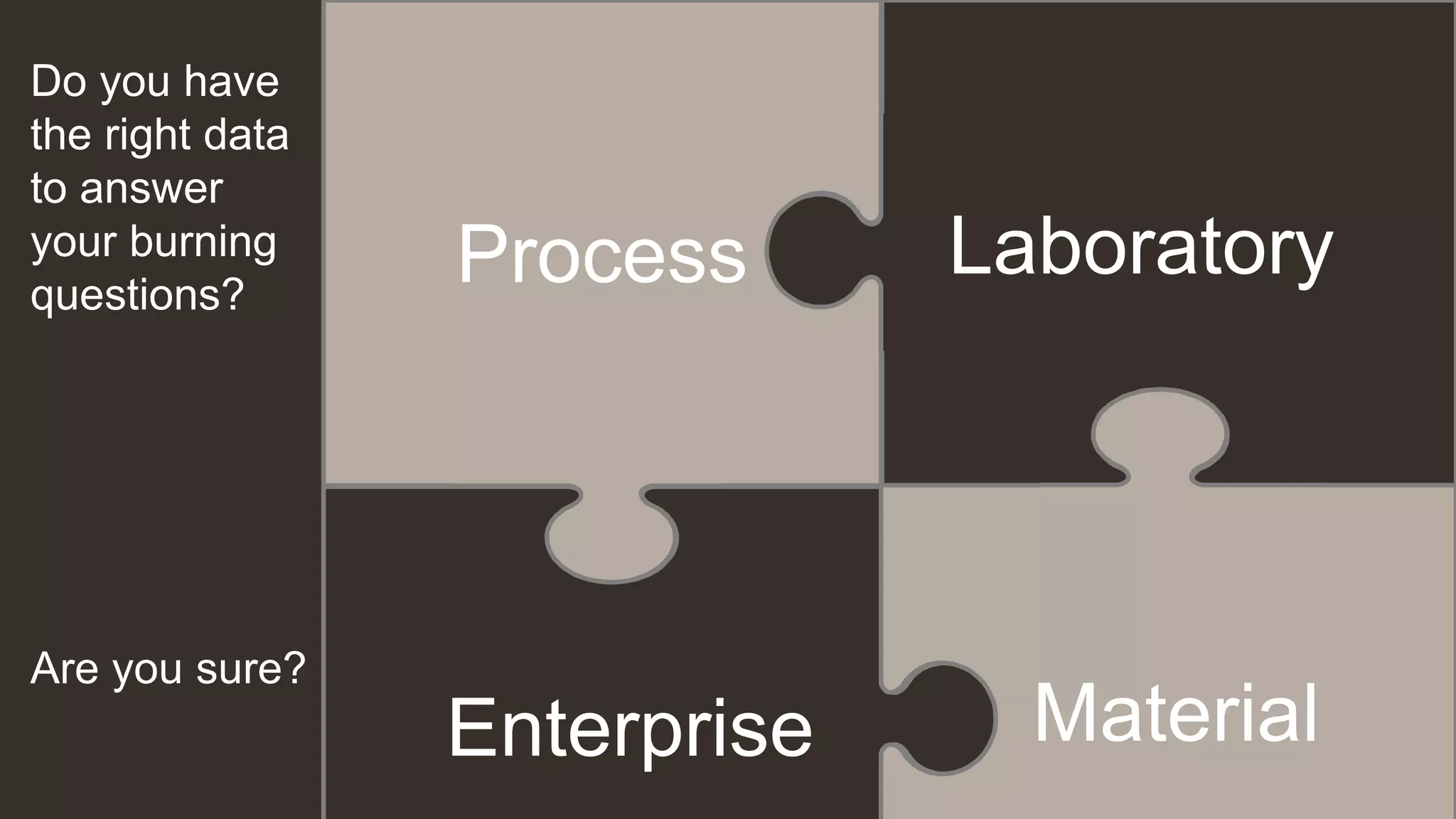

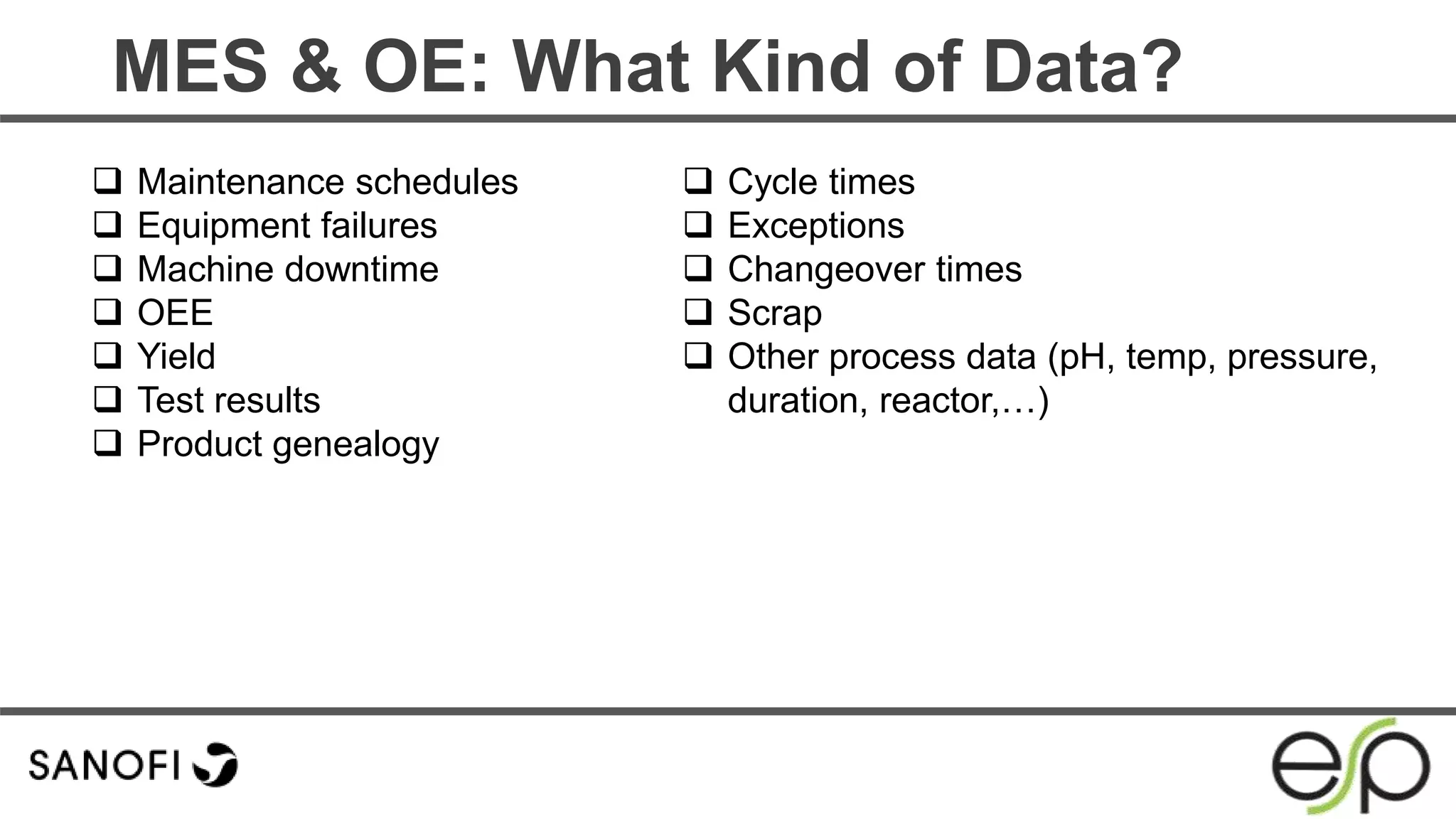

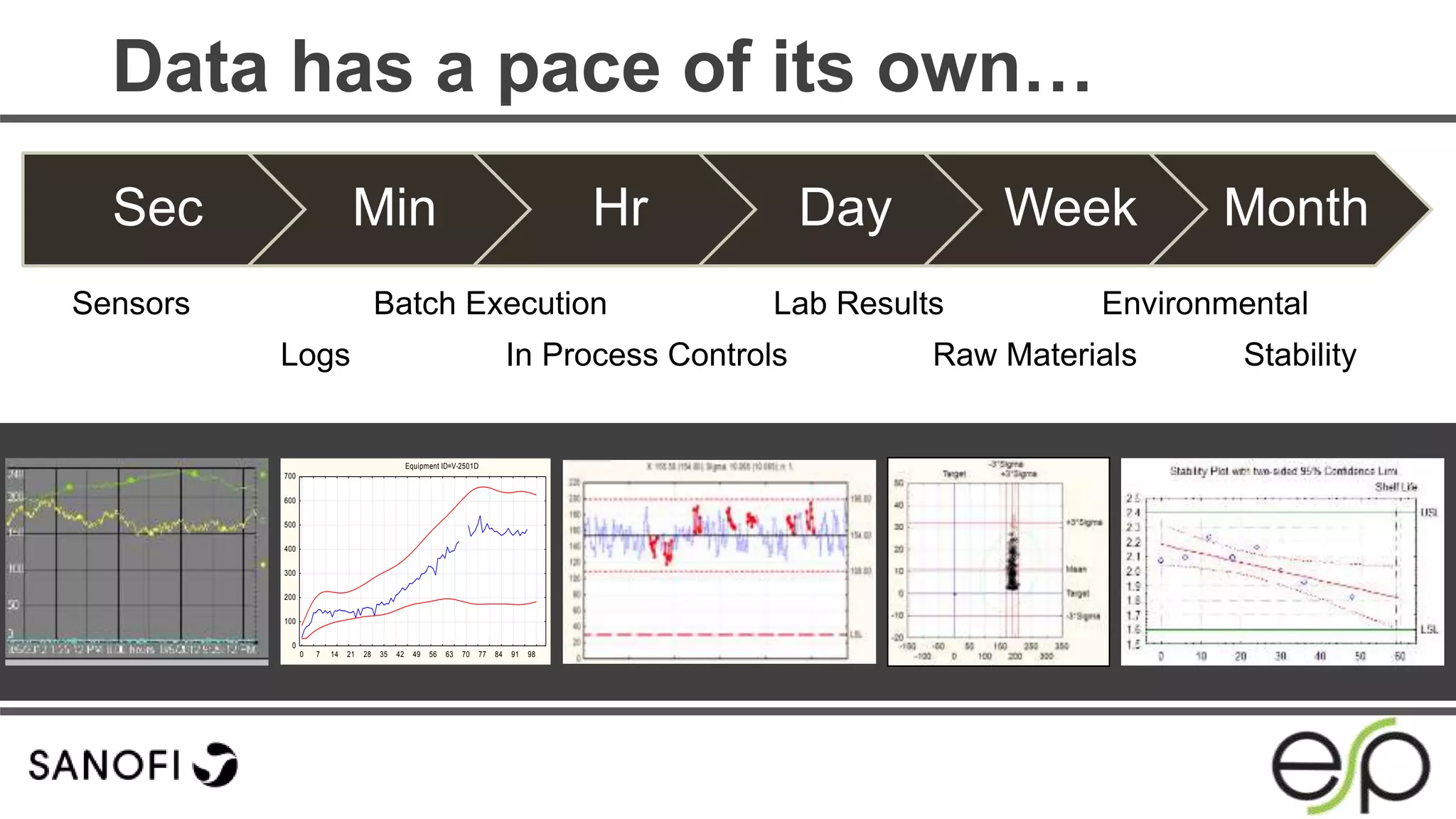

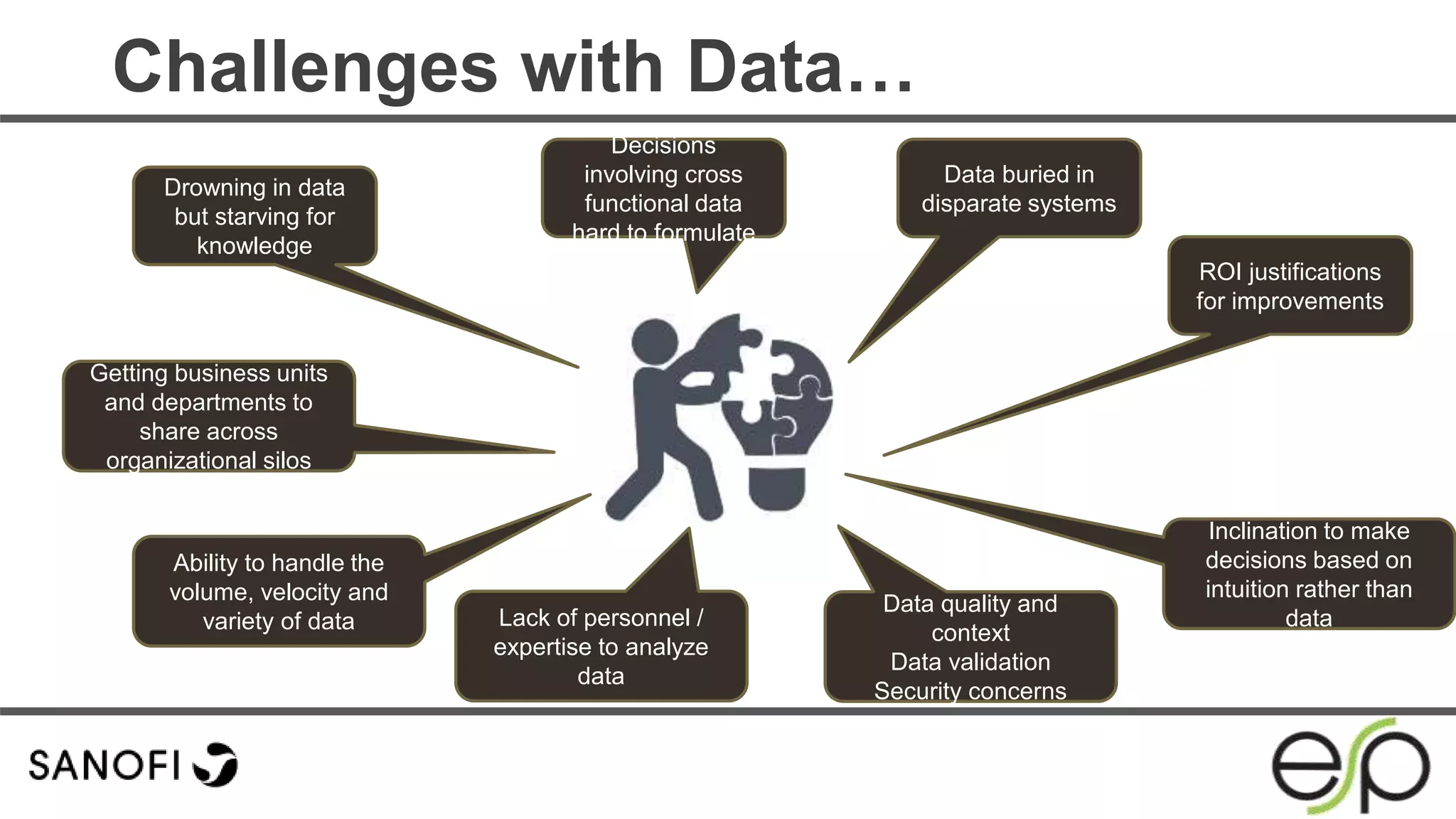

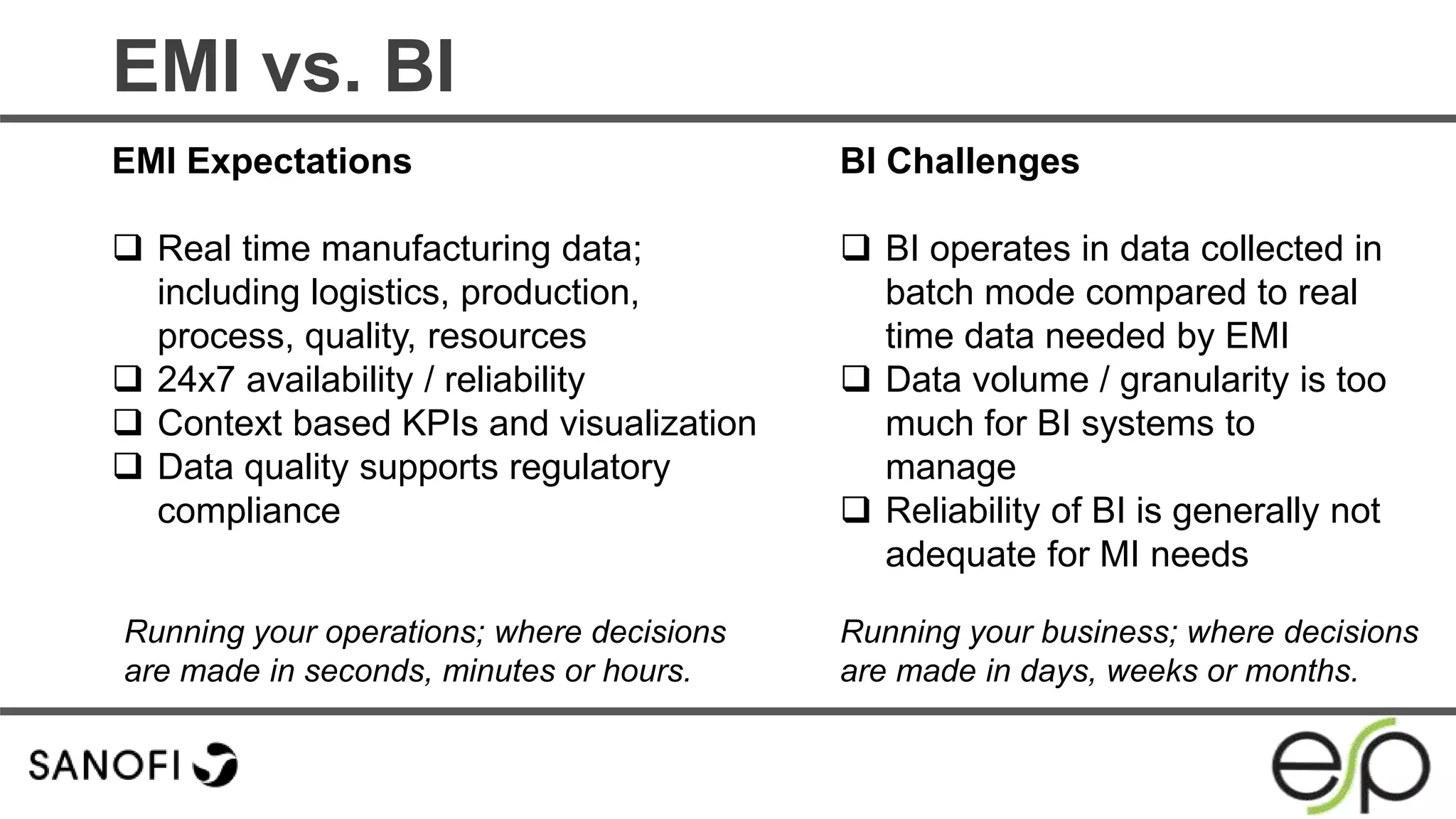

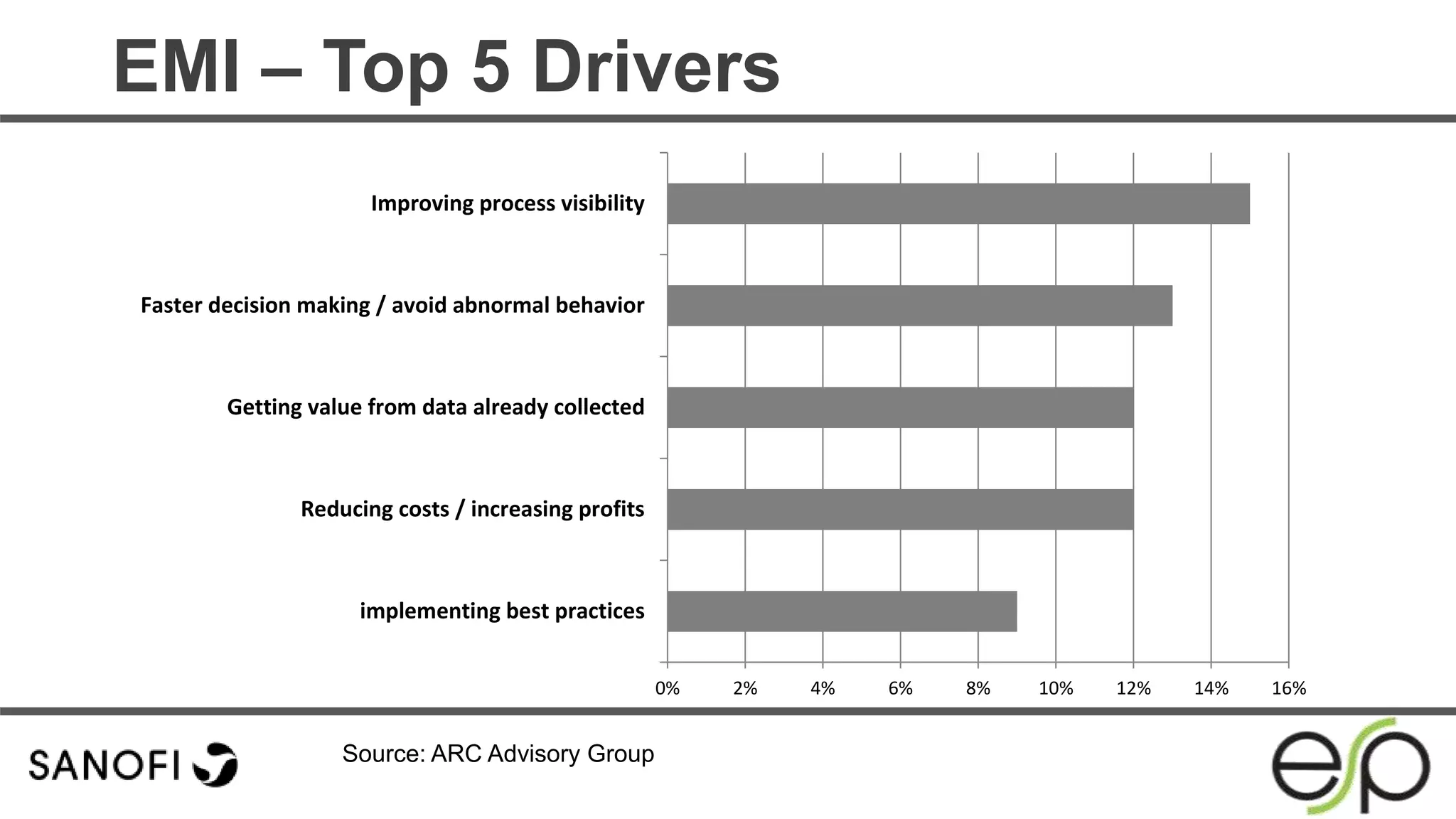

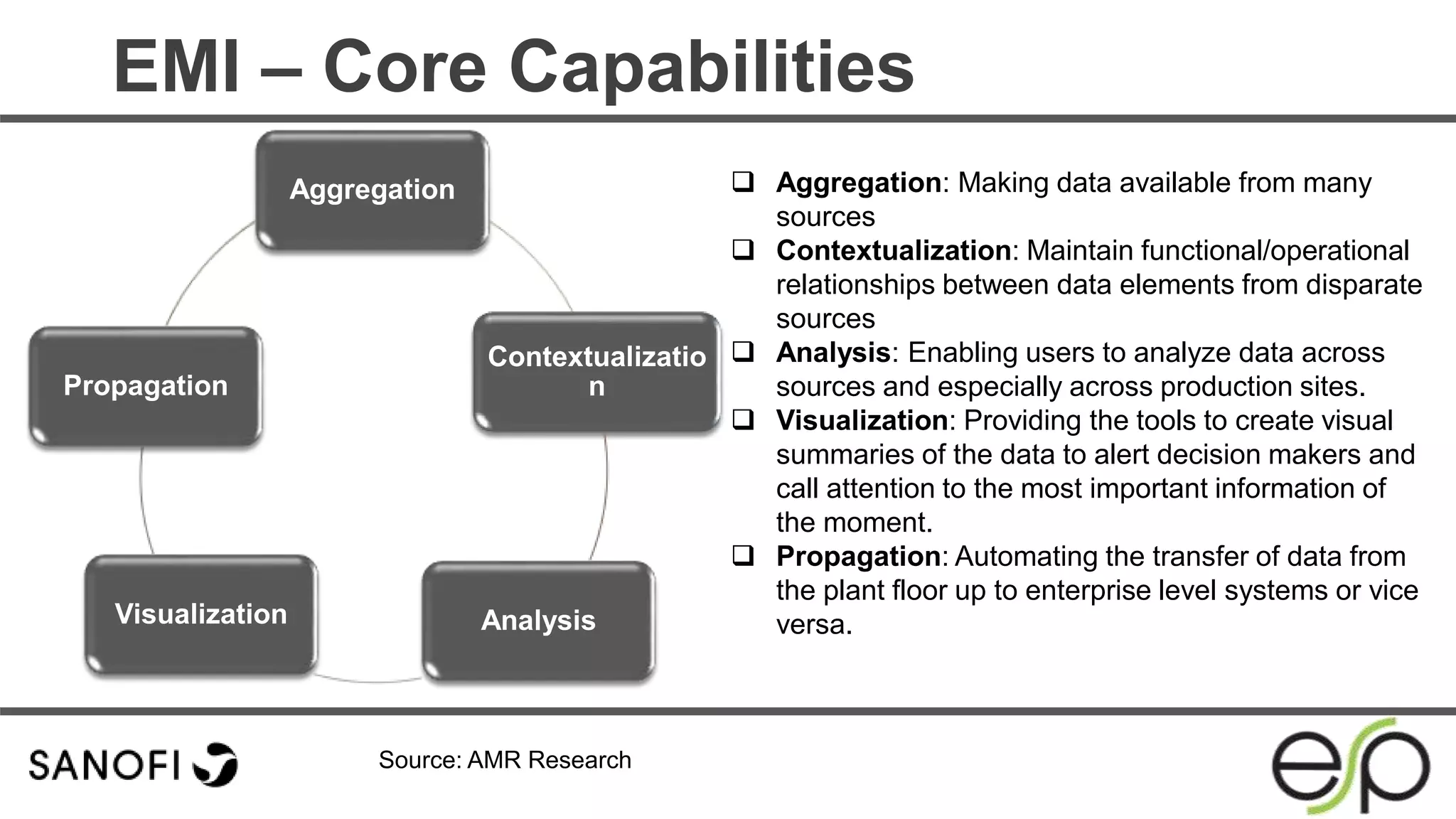

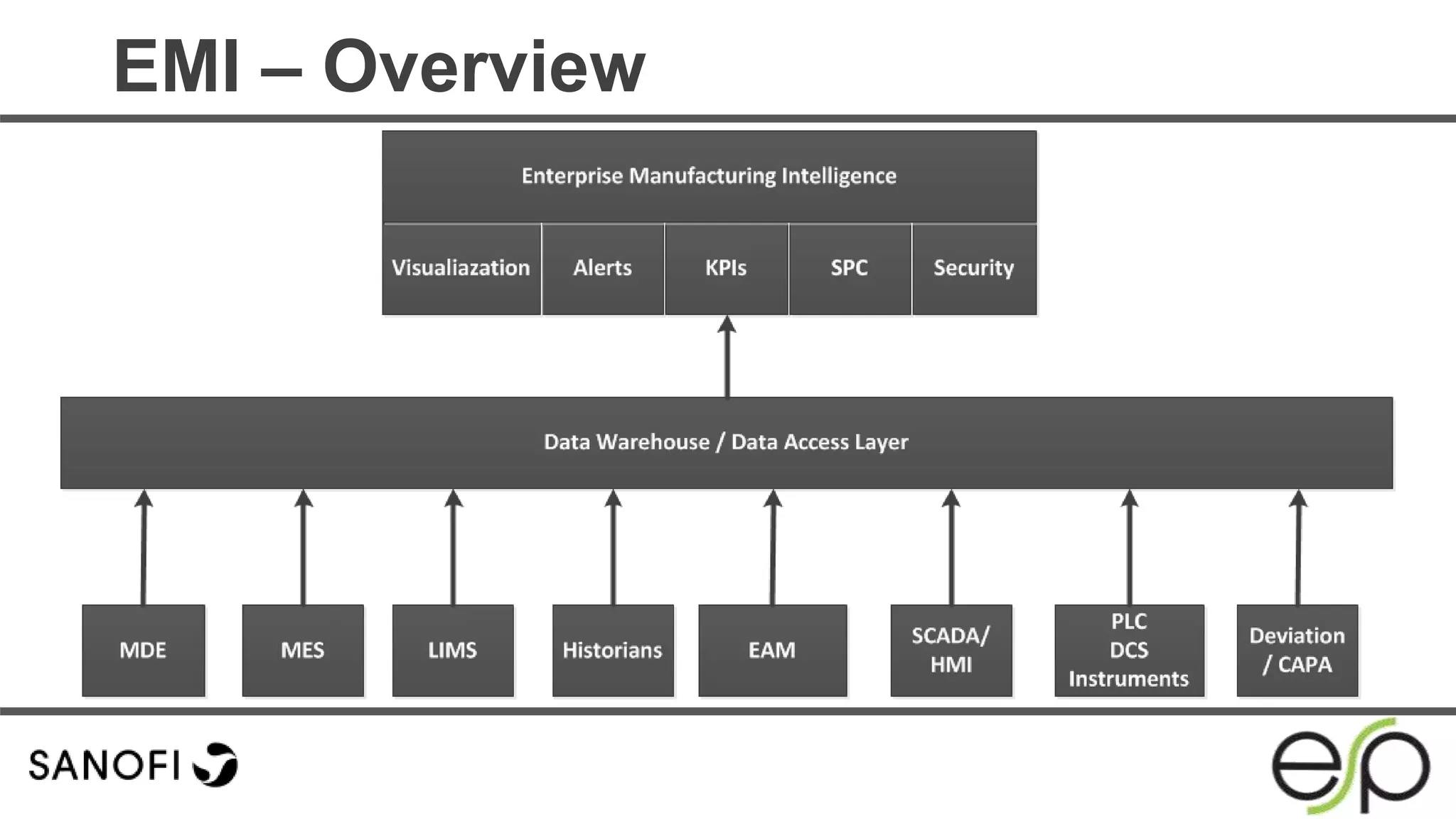

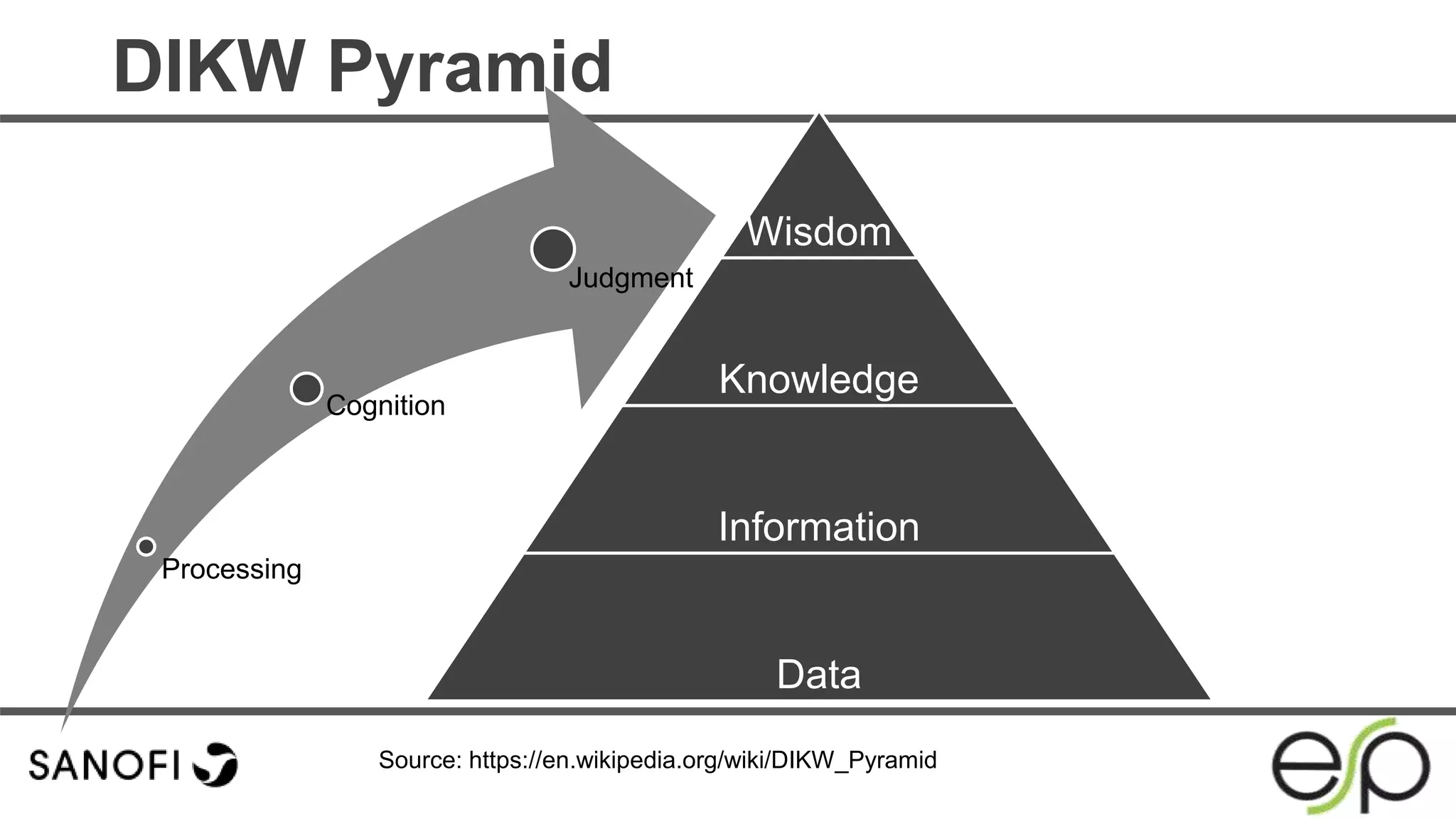

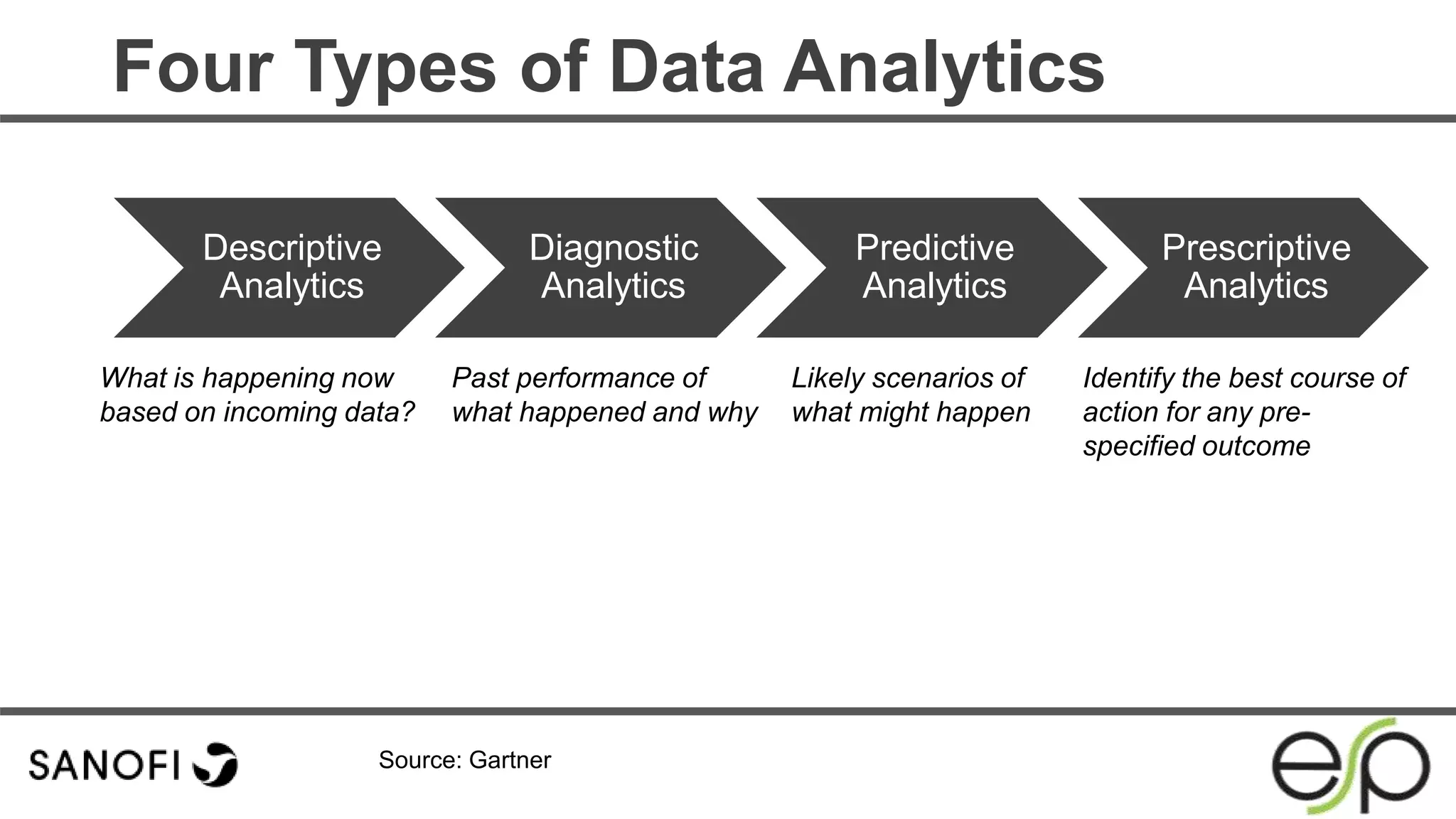

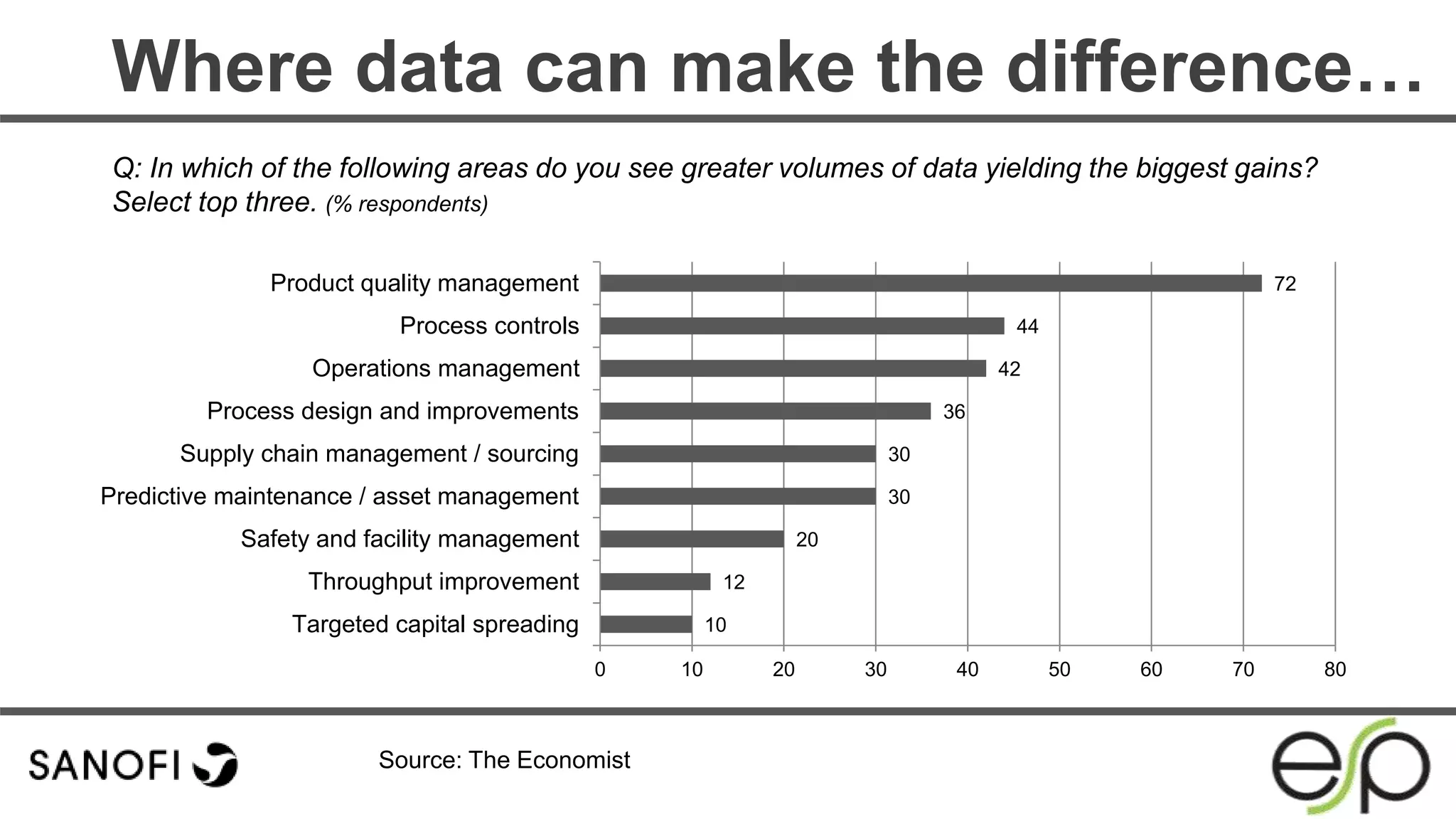

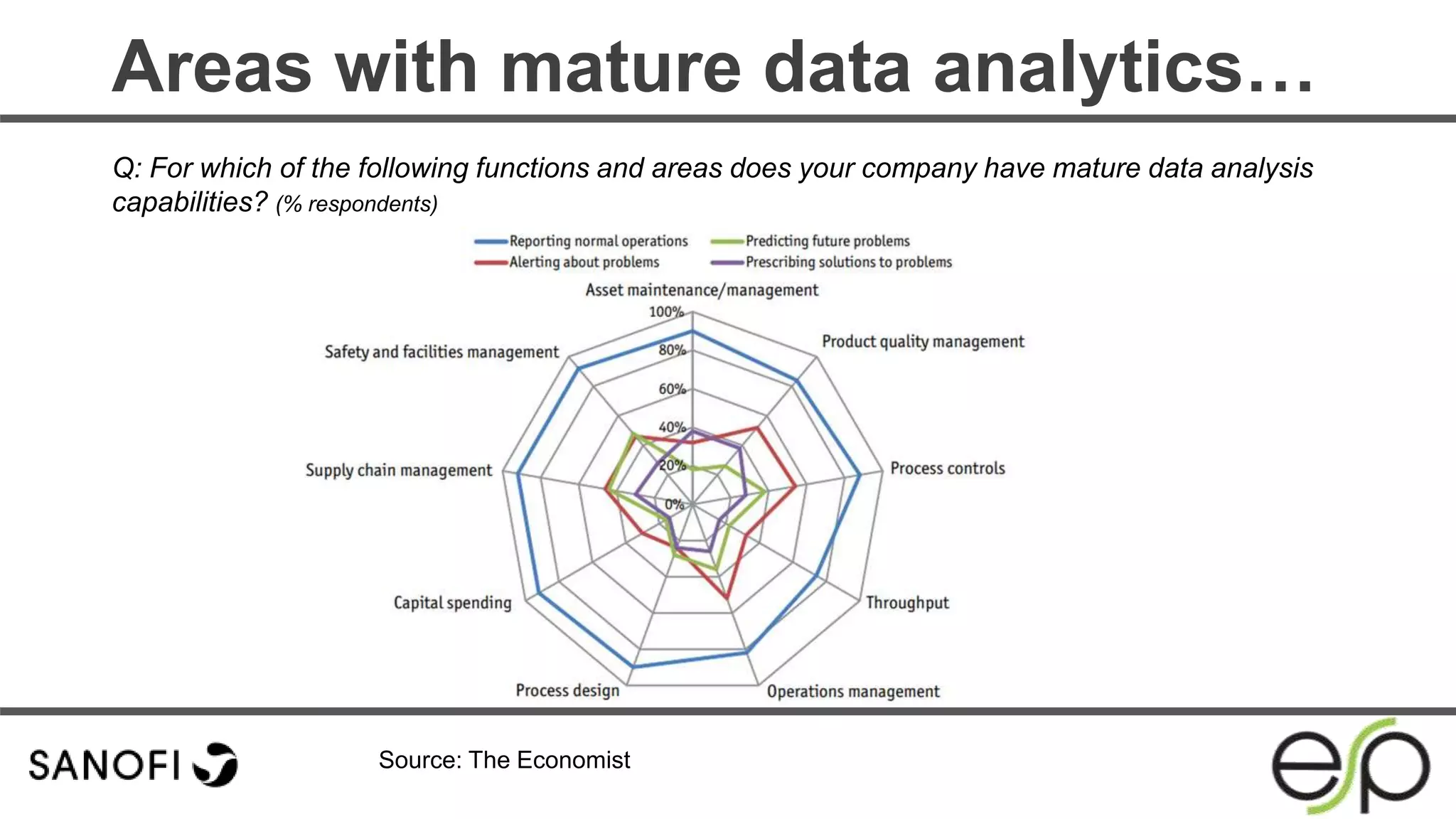

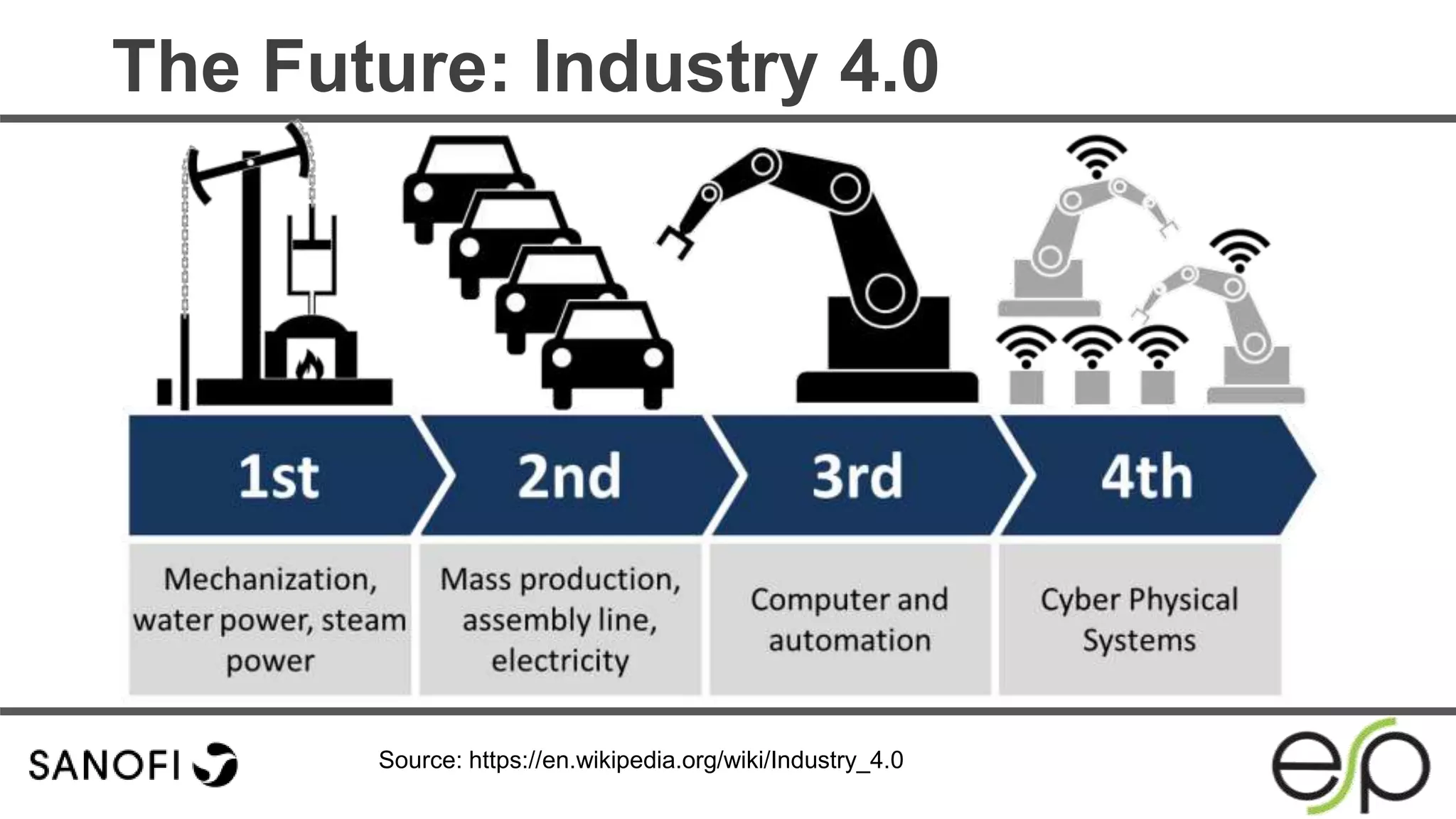

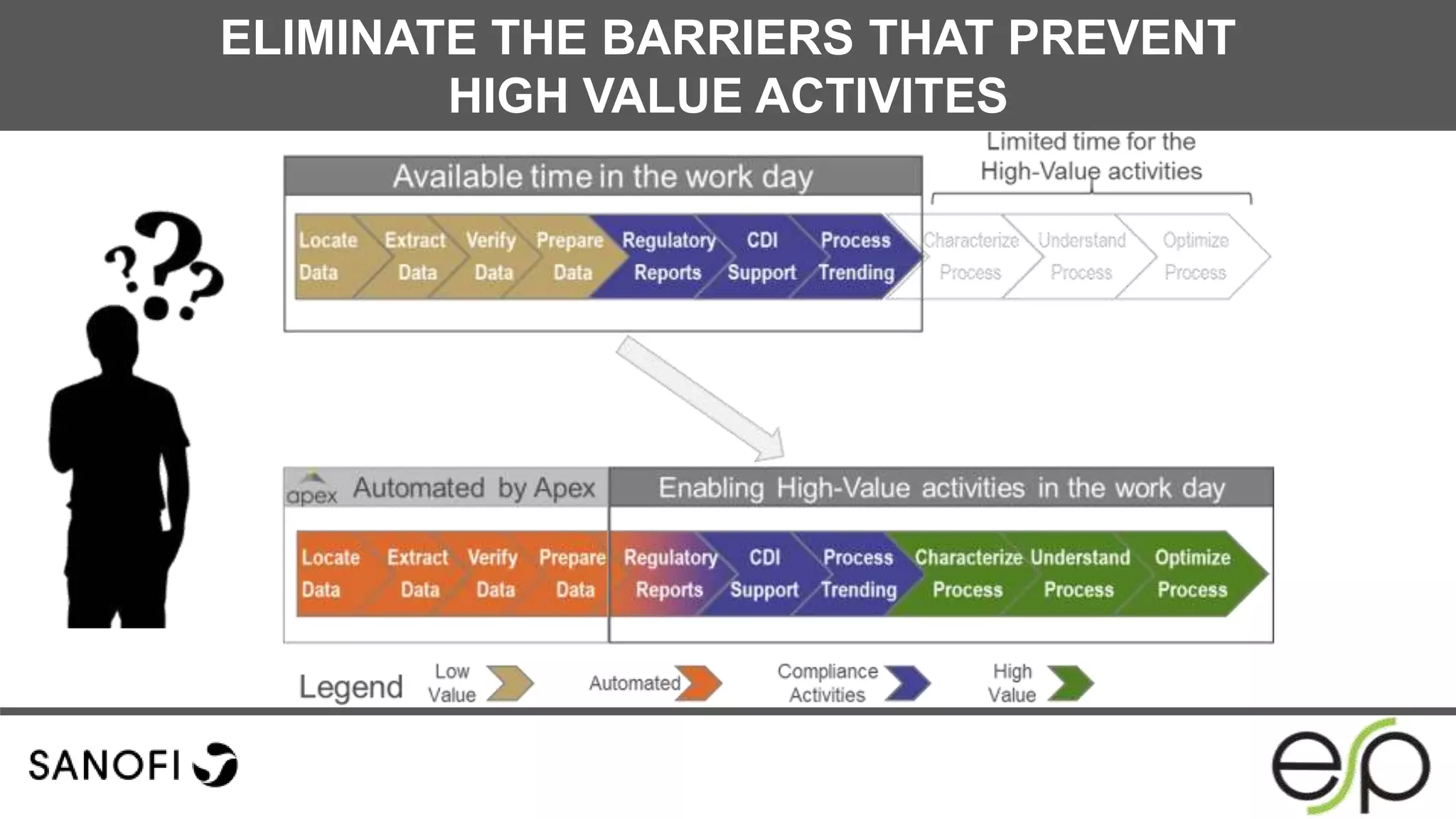

The document discusses leveraging manufacturing data from Manufacturing Execution Systems (MES) to improve operational excellence. It describes how MES data can be used to increase productivity, quality, and efficiency while reducing costs and waste. However, simply collecting large amounts of data is not sufficient; the key is proactively using data analytics and Enterprise Manufacturing Intelligence to transform into a knowledge-driven organization that can improve processes in real-time.