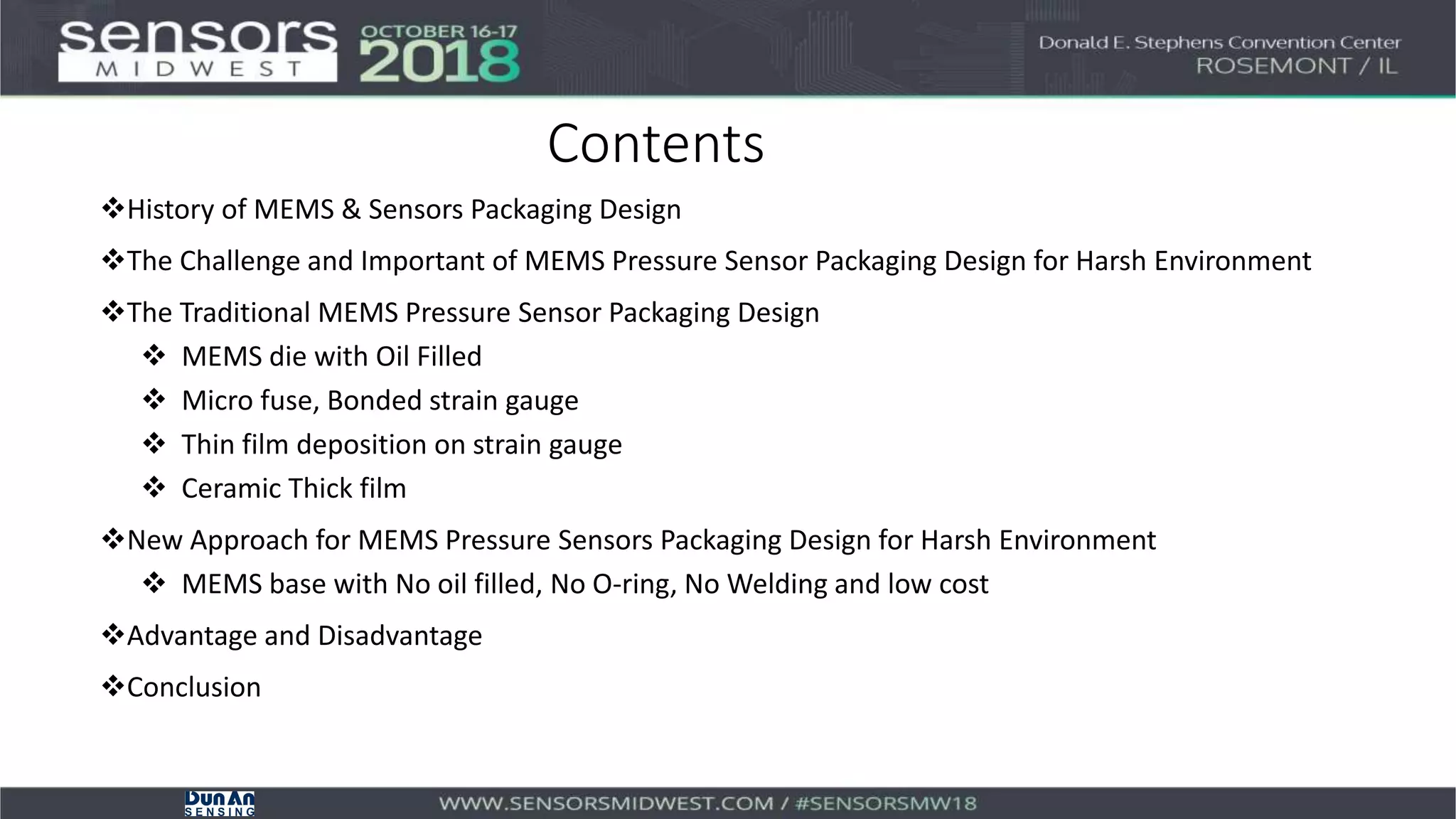

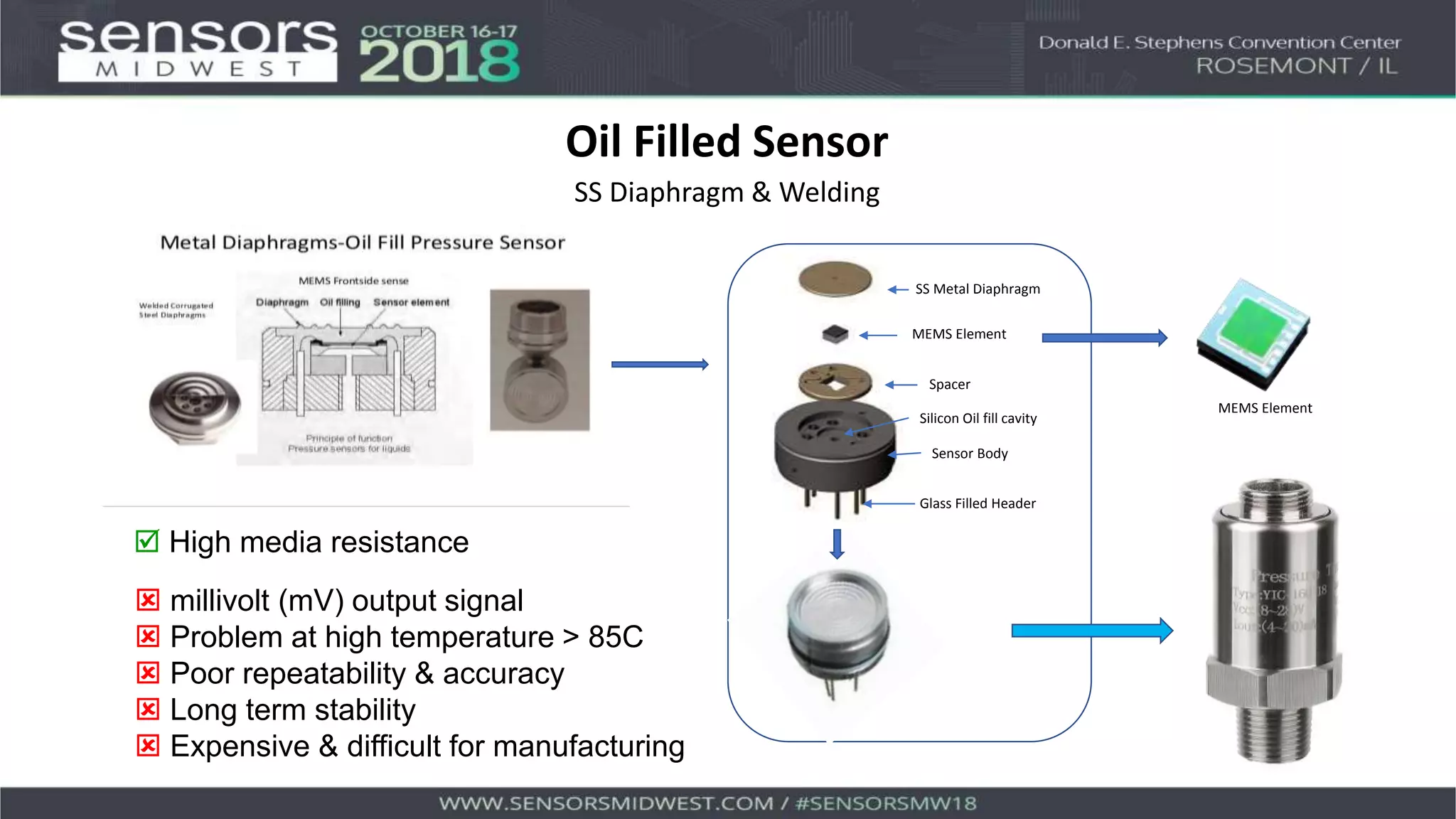

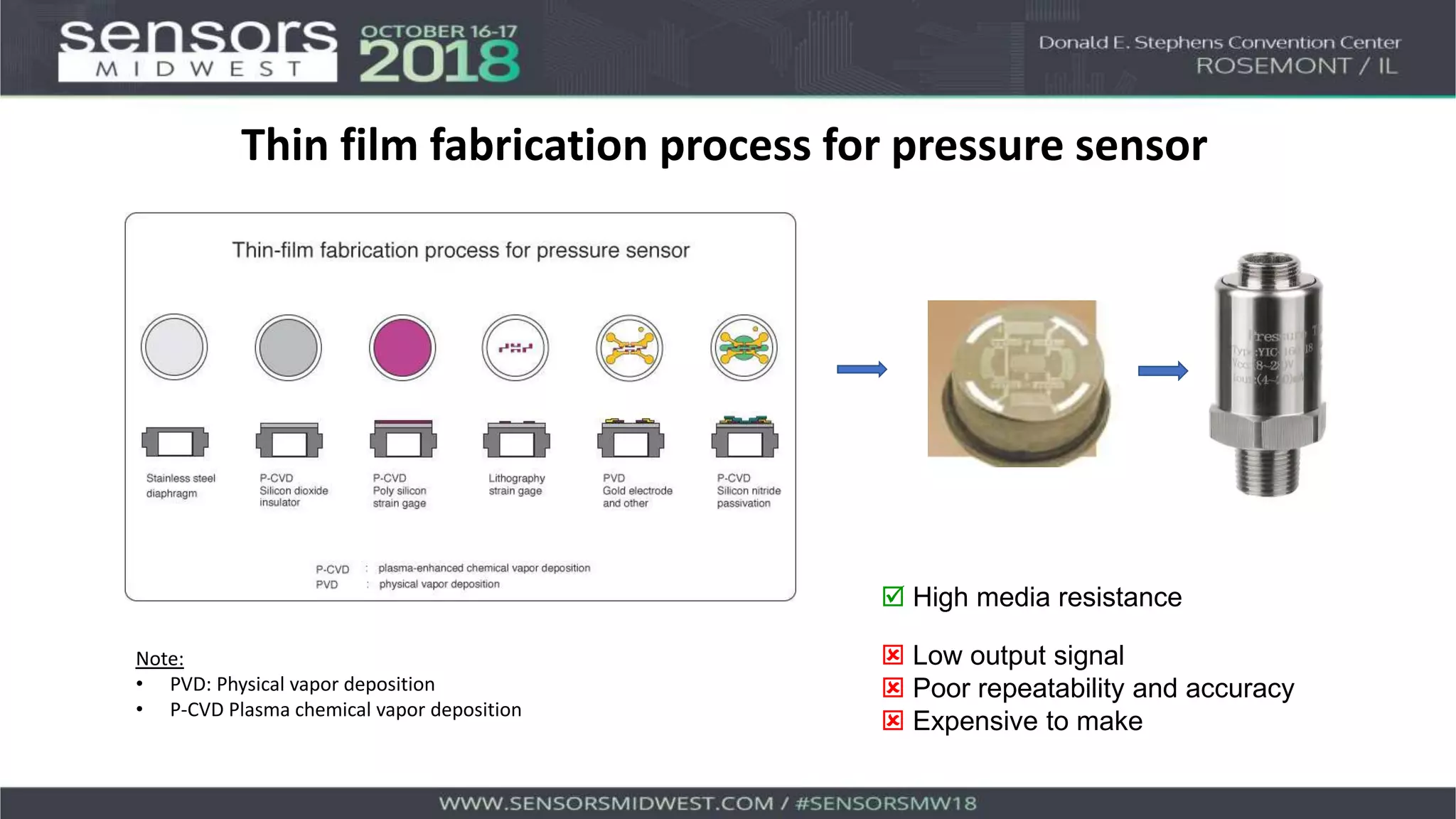

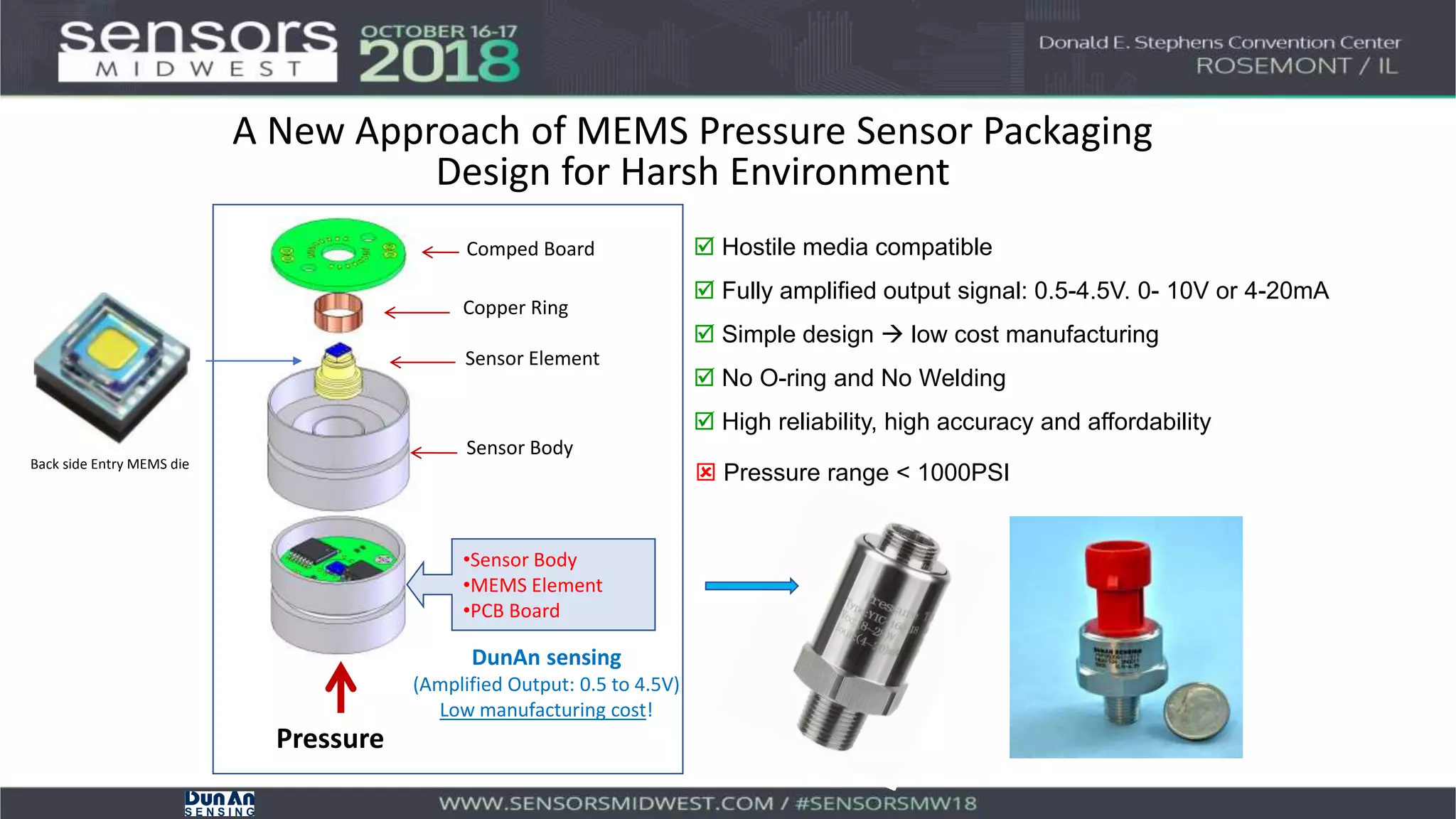

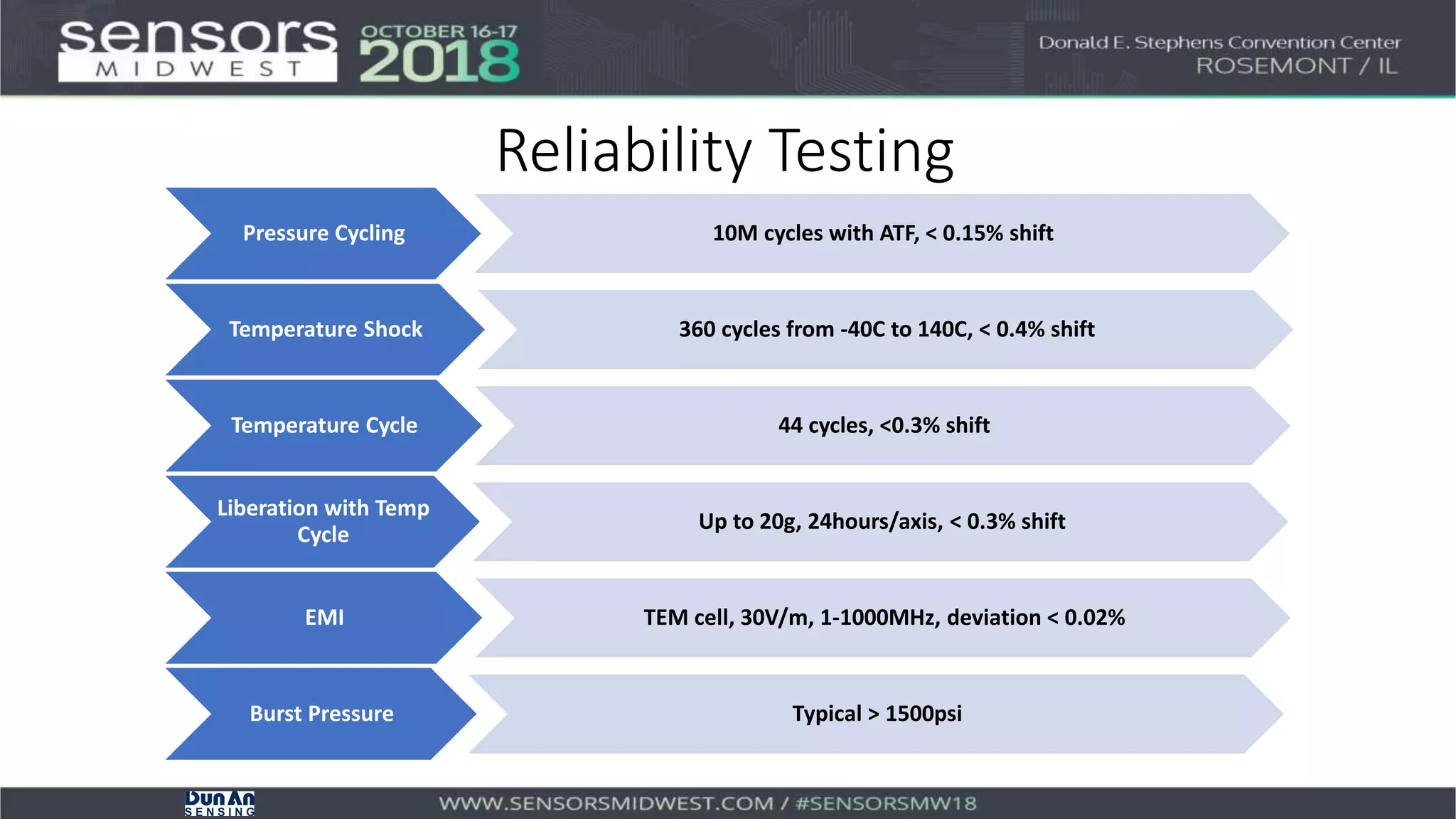

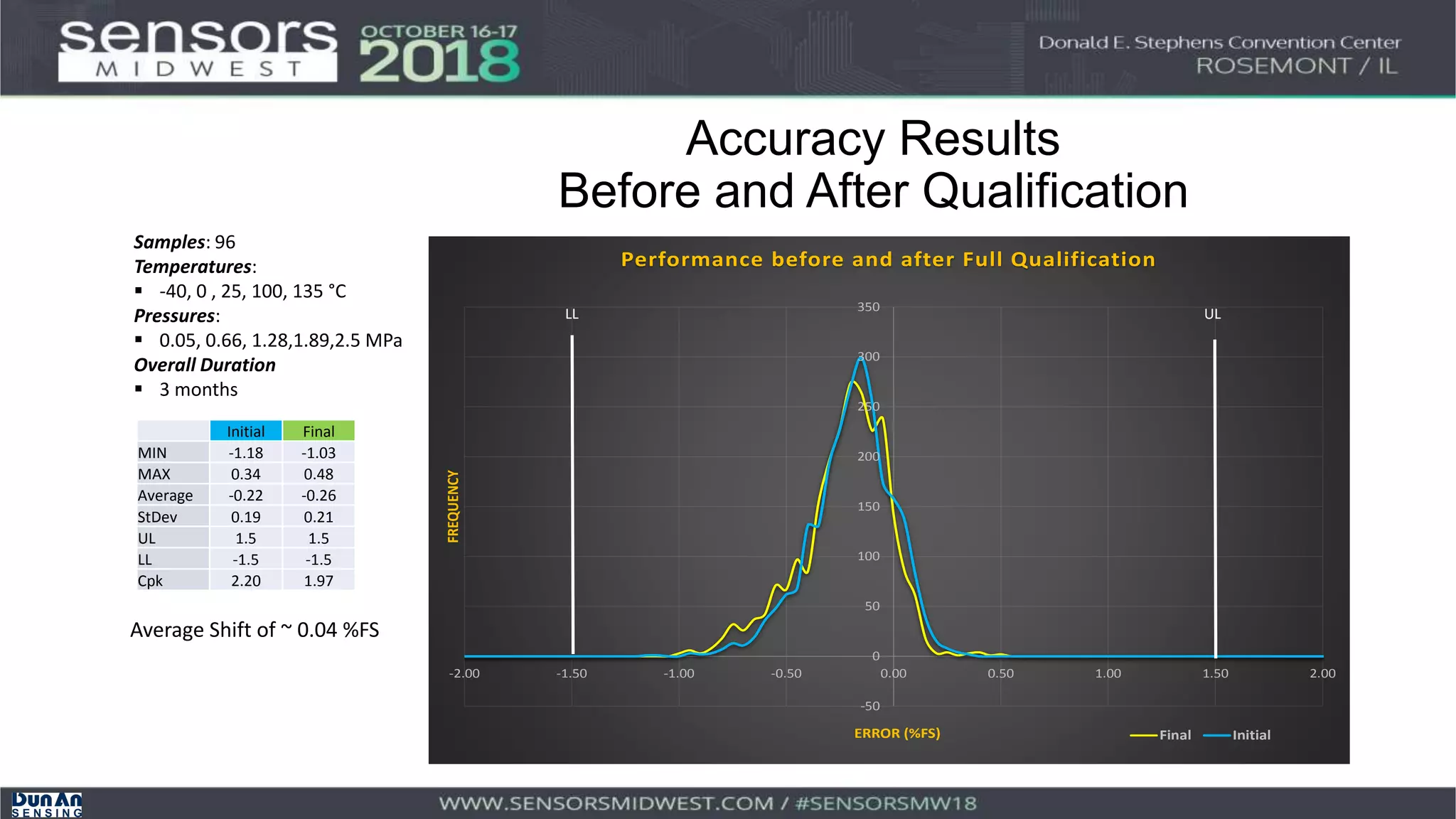

The document discusses the challenges of designing MEMS pressure sensor packaging for harsh environments, emphasizing the critical role packaging plays in sensor performance and cost. Tom Nguyen, the founder of Dunan Sensing, outlines new approaches to enhance the accuracy, reliability, and affordability of these sensors while addressing issues related to media compatibility, thermal and mechanical stress, and environmental testing. The conclusion highlights the need for innovative packaging solutions to ensure successful large-scale production in the MEMS and sensor industry.