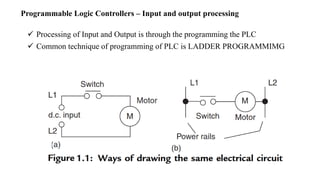

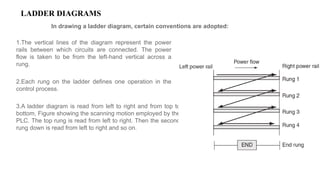

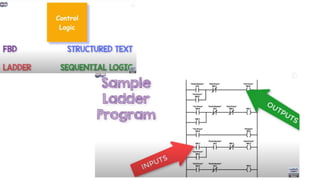

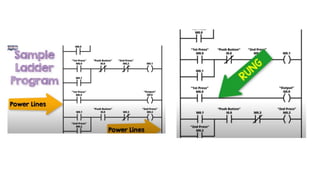

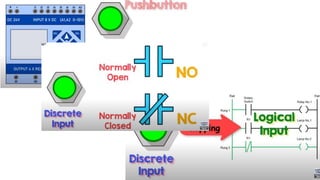

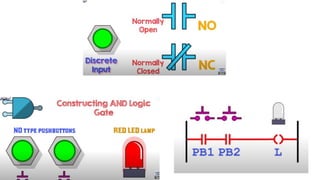

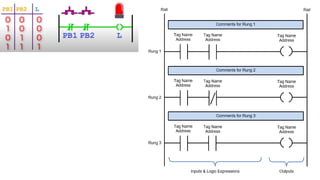

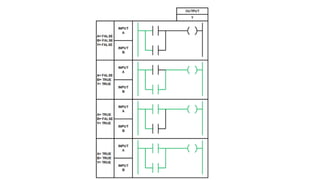

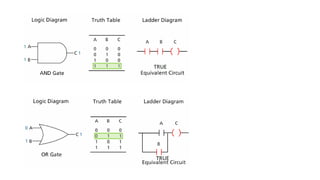

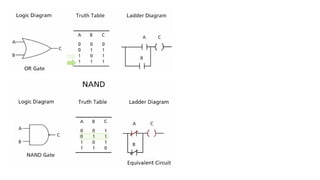

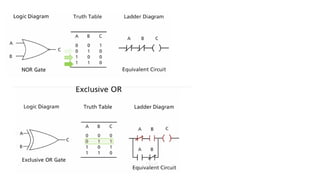

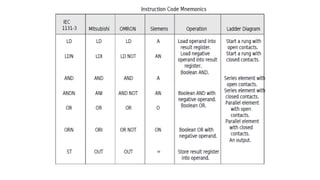

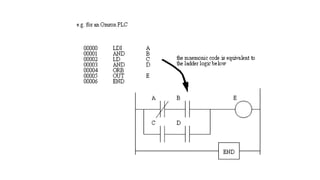

This document discusses programmable logic controllers (PLCs), including their basic structure, input/output processing, and programming. It notes that PLCs process inputs and outputs through programming, with ladder programming being a common technique. Ladder diagrams follow certain conventions, such as each rung defining one operation and starting with an input and ending with an output. Inputs and outputs are identified by their addresses in the PLC's memory.