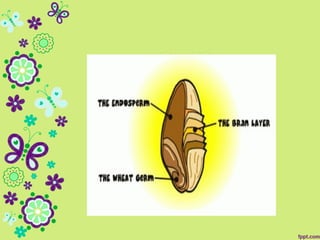

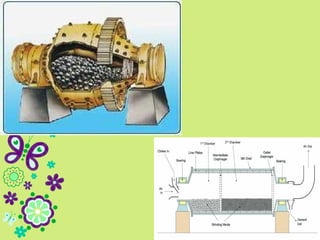

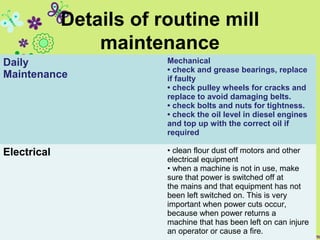

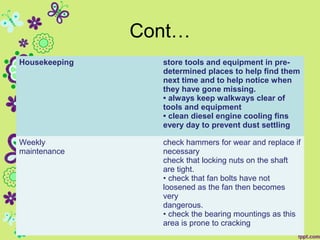

Milling is the process of converting grains into flour. There are different types of mills used for milling like hammer mills, roller mills, and ball mills. Routine maintenance of mills includes daily cleaning and greasing of parts, weekly checks of hammers and nuts, and monthly inspections of welds and foundations. Safety precautions when operating mills include using personal protective equipment, avoiding loose clothing, and applying hand sanitizer. Mill efficiency can be improved by reducing non-processing times and optimizing feed rates and spindle speeds.