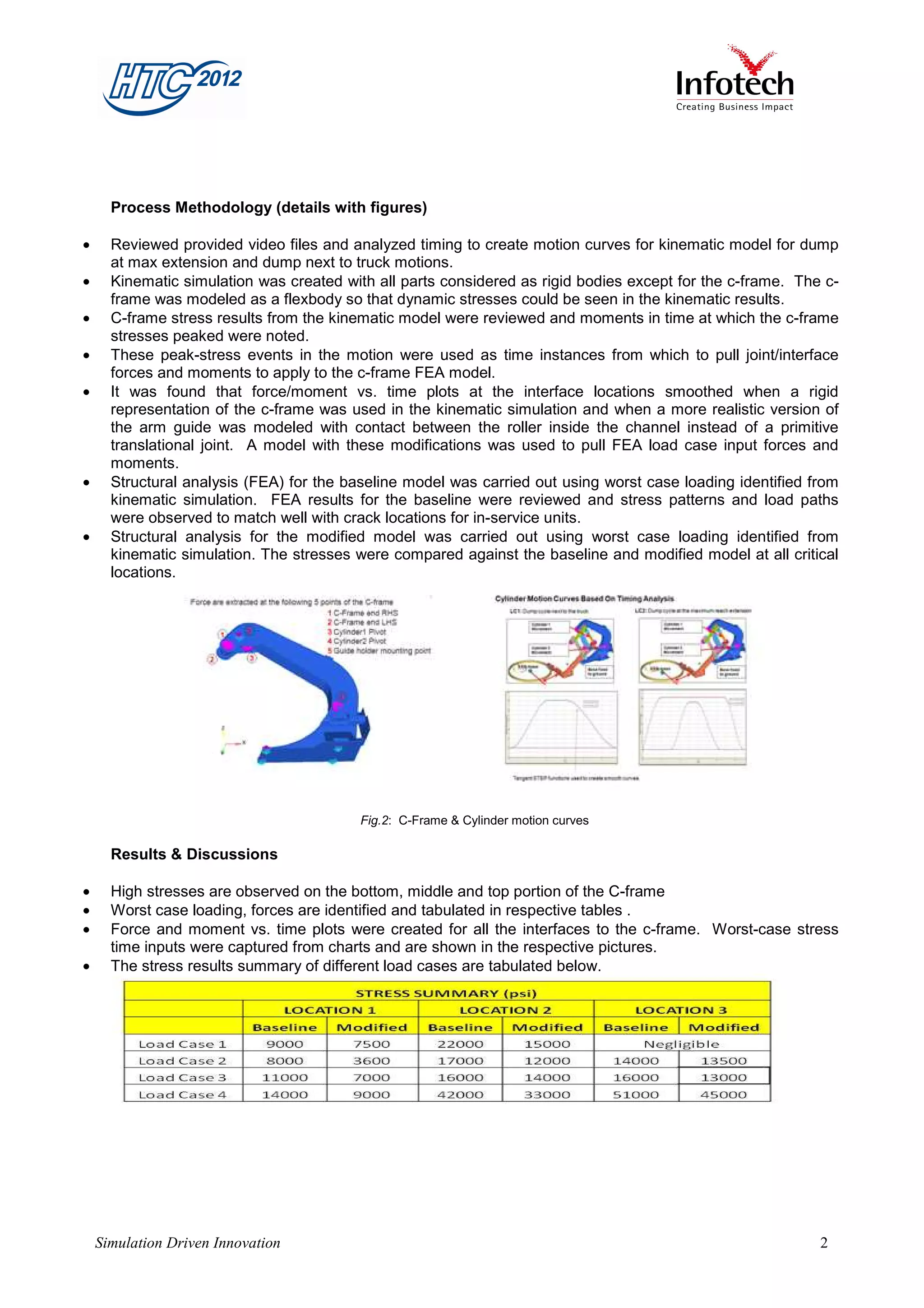

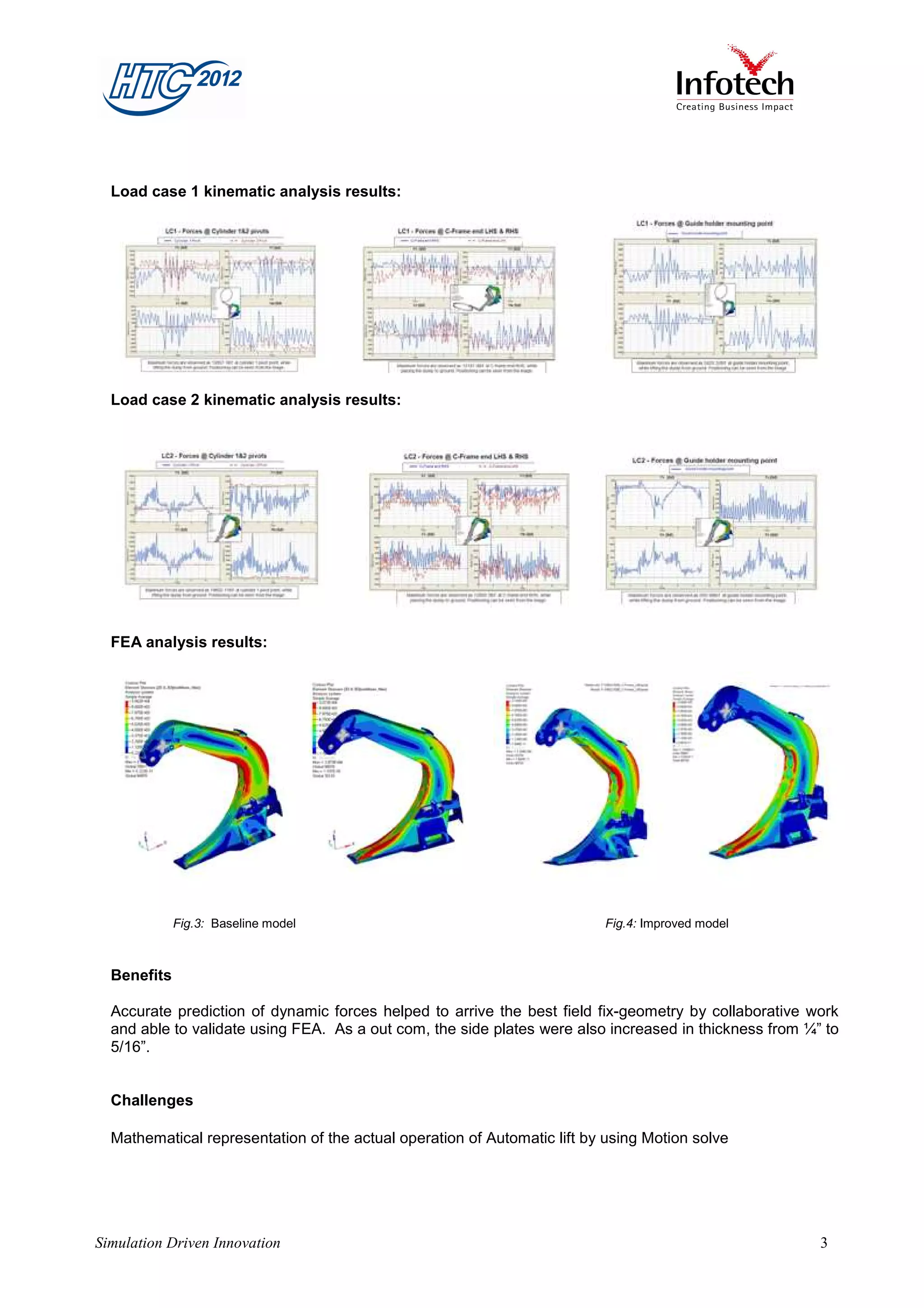

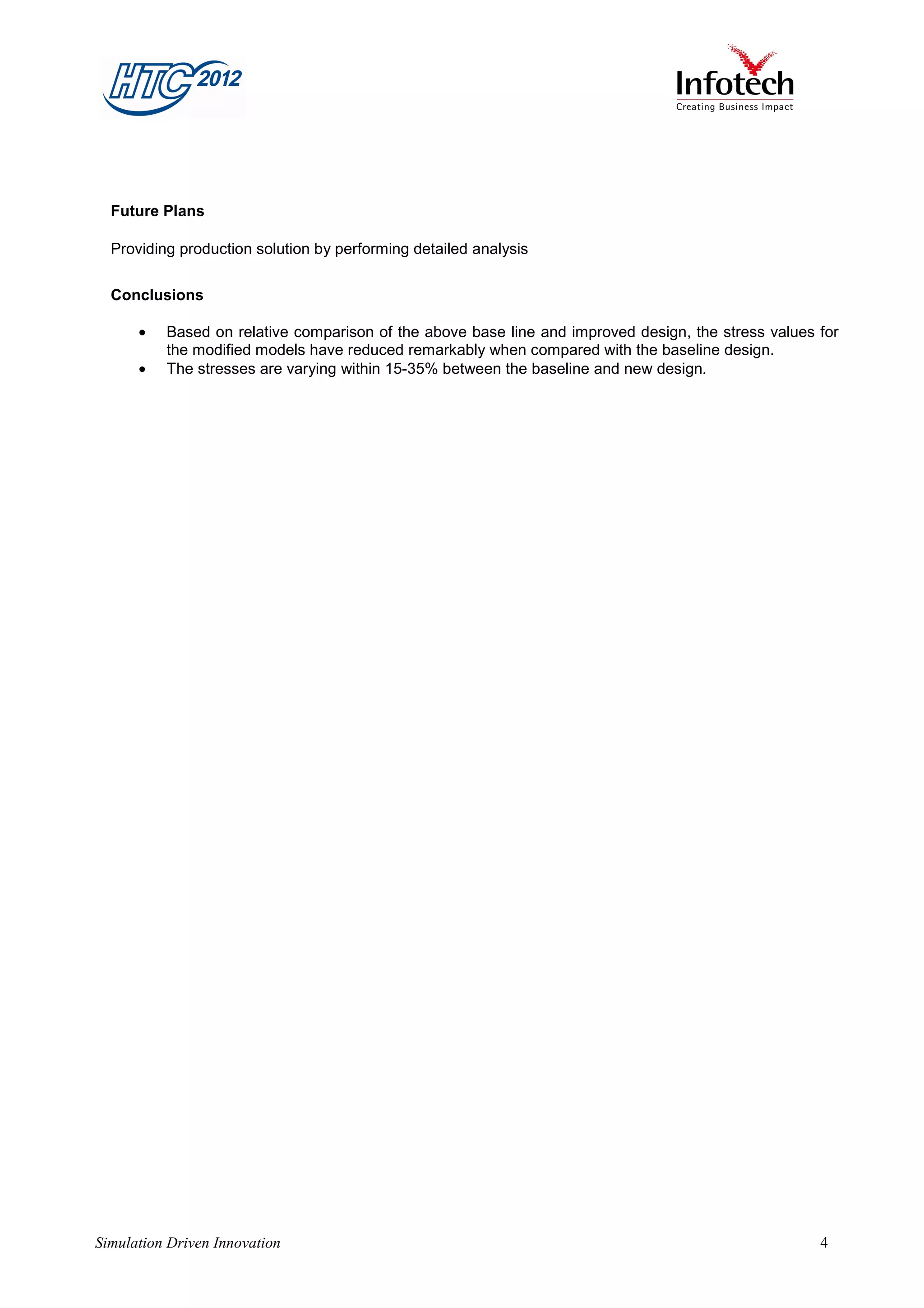

This document discusses the kinematic and structural simulation of an automated lift used in garbage collection trucks. The simulation aimed to address field failures of the lift's C-frame. Kinematic simulation identified worst case loading scenarios. Structural analysis of the baseline model matched stress patterns to known crack locations. A modified model with increased plate thickness showed reduced stresses. The accurate modeling and simulation helped validate an improved field fix design and reduce stresses by 15-35% compared to the baseline.