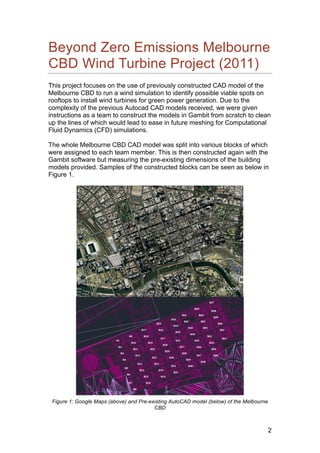

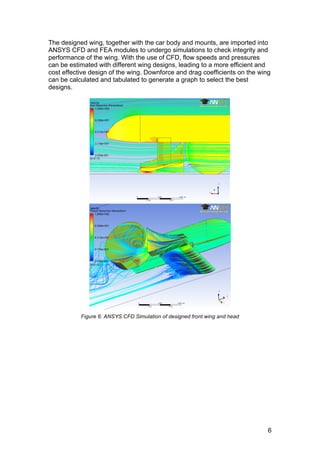

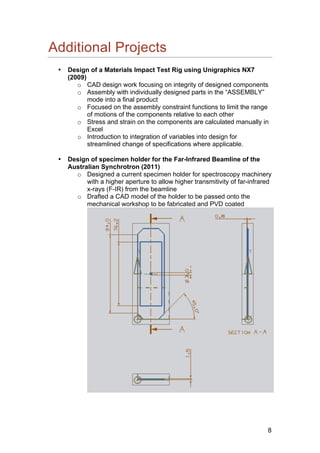

This document summarizes two major CAD and simulation projects completed by the author for their university studies. The first project involved modeling the Melbourne CBD in CAD to identify potential locations for wind turbines, with the author modeling several city blocks. The second was a race car front wing design project where the author designed and simulated a front wing in CAD and FEA/CFD software. Smaller additional projects involving an impact test rig and infrared spectroscopy sample holder are also mentioned.