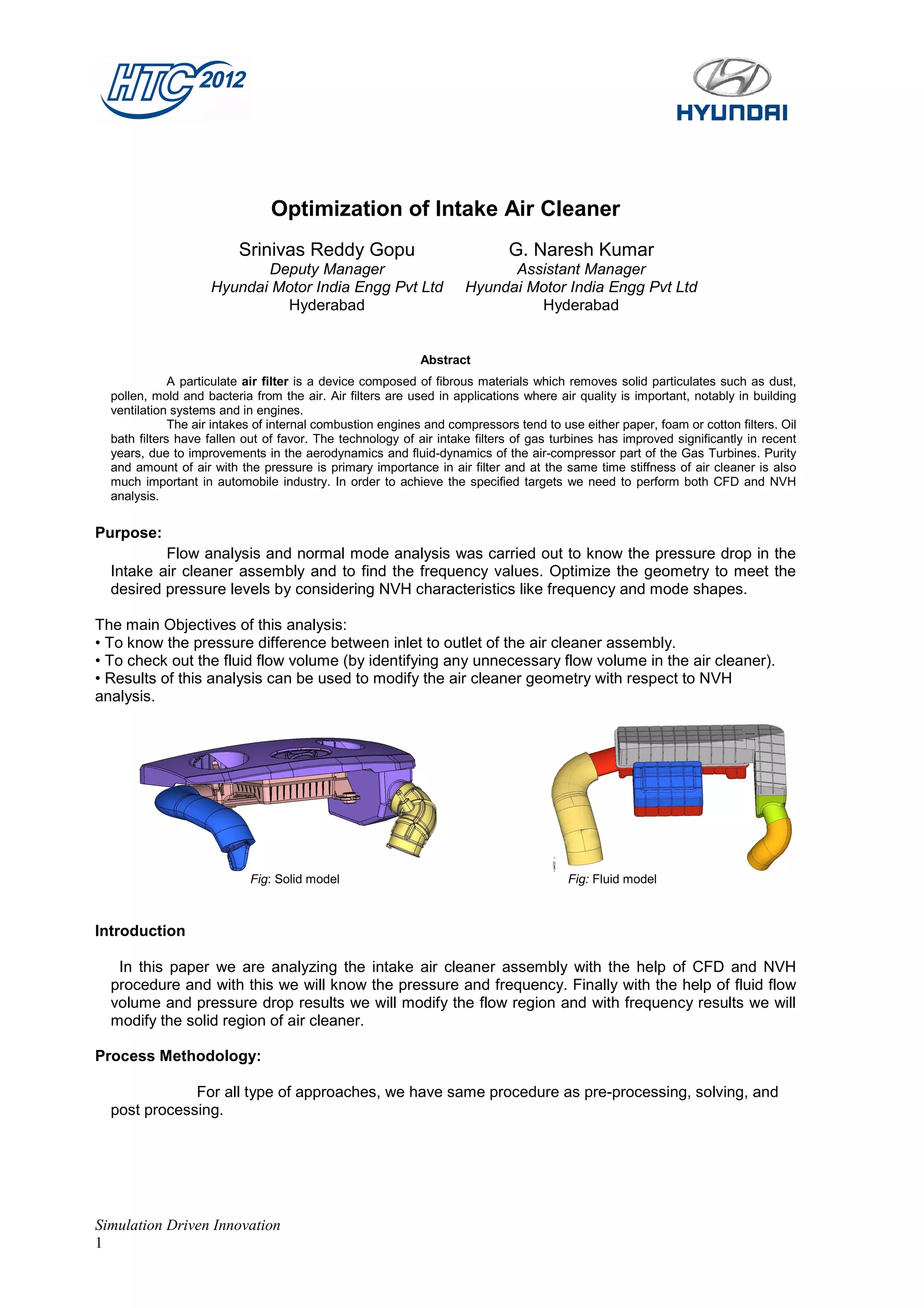

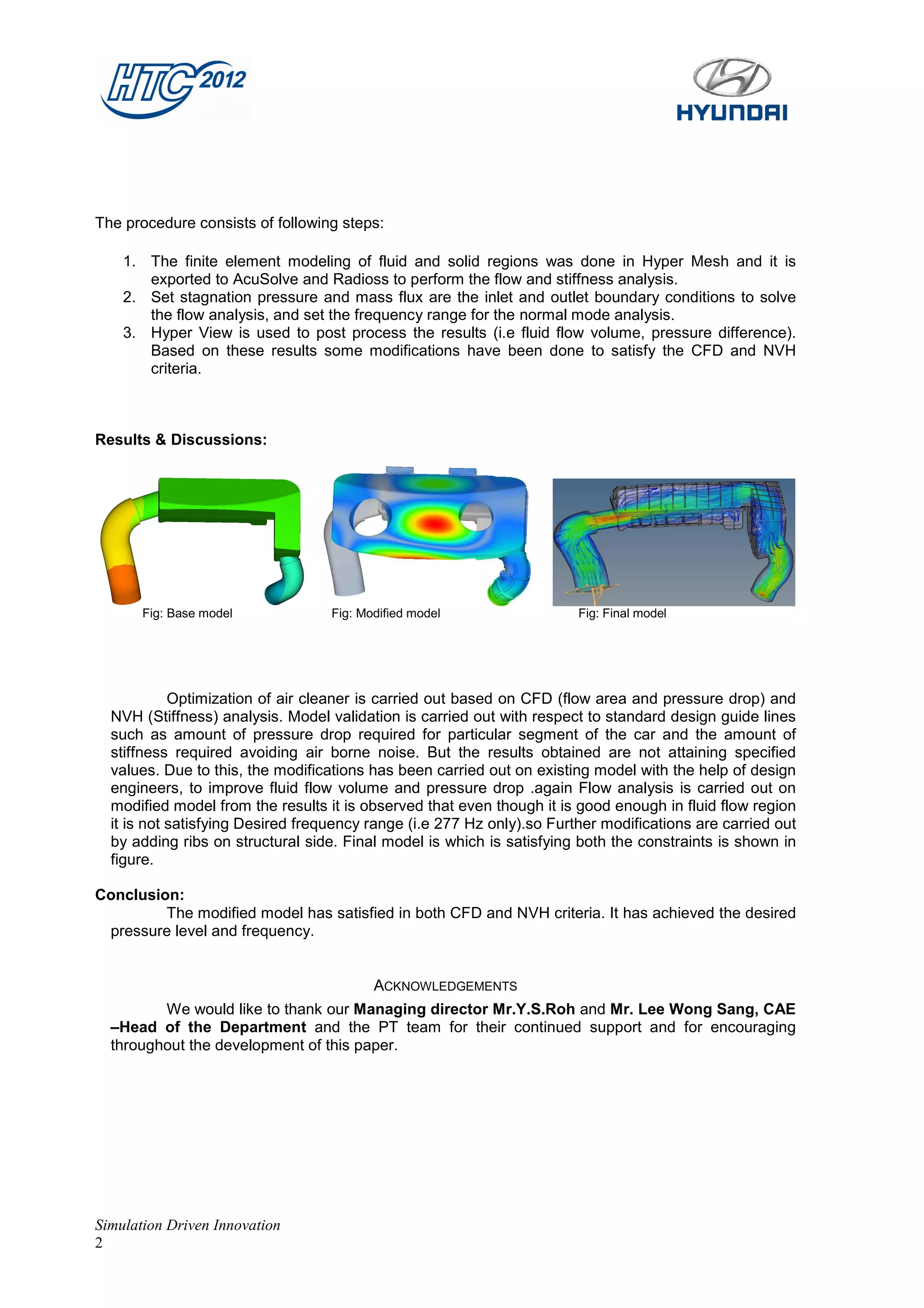

The document summarizes optimization of an intake air cleaner through computational fluid dynamics (CFD) and noise, vibration, and harshness (NVH) analysis. The analysis aims to meet pressure and frequency targets. Modifications are made to the geometry to improve airflow and reduce pressure drop based on CFD results. Additional modifications with ribs are made to satisfy the desired frequency range based on NVH analysis. The final modified model meets both the CFD and NVH criteria by achieving the targeted pressure level and frequency.