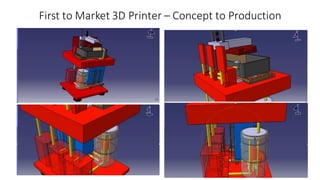

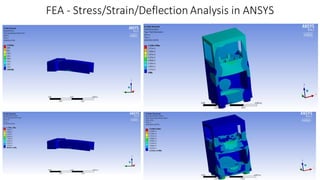

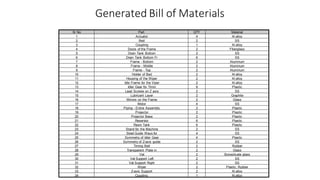

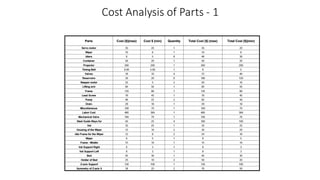

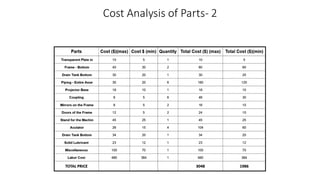

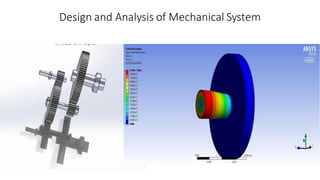

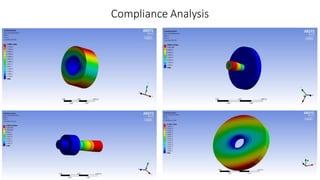

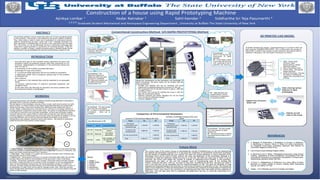

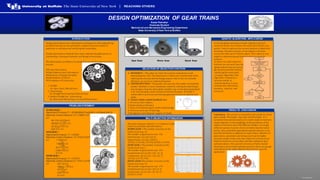

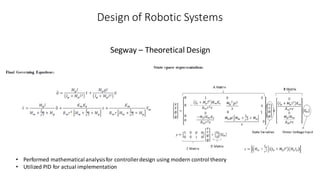

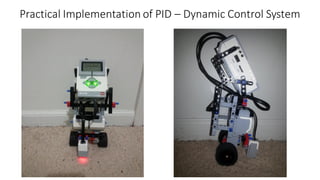

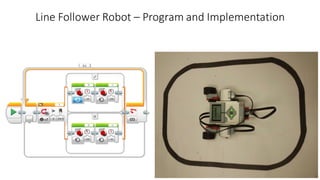

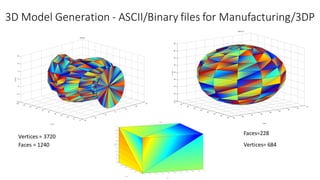

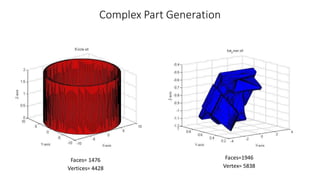

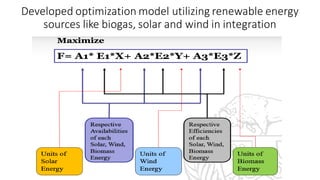

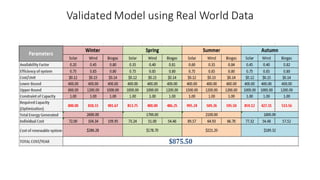

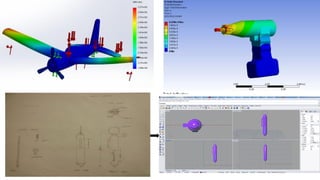

Kedar Ratnakar is a mechanical engineer passionate about product design, controls, and manufacturing. Their portfolio highlights projects including developing an innovative multi-material 3D printer and bringing a 3D printer concept to production. They have experience with CAD software, finite element analysis, bill of materials generation, cost analysis, and computer integrated manufacturing. Kedar has also designed robotic systems, generated 3D models for manufacturing, and developed Arduino applications for electro-mechanical systems.