Embed presentation

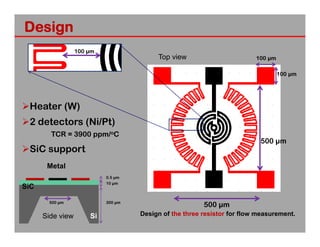

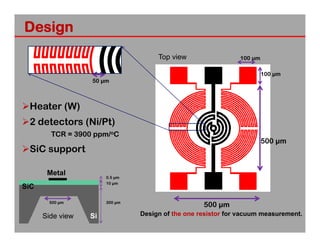

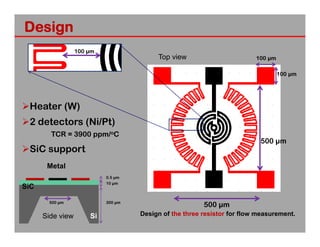

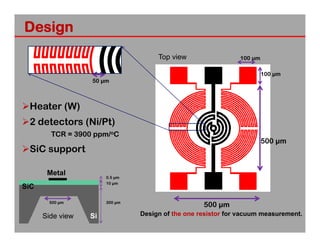

The document describes the design of a MEMS sensor to measure fluid flow parameters such as flow rate, velocity, direction, and pressure using hotwire principles. It involves designing resistive elements on a silicon carbide substrate that can produce heat when current is passed through and allow changes in temperature to be detected. Fabrication of low-cost silicon carbide is also discussed using porous silicon as a template in a chemical vapor deposition process. The sensor aims to provide accurate readings of flow and pressure in applications such as aerospace, medical devices, automotive, and semiconductor manufacturing.