This document provides information about varnishes, including what they are, their components and manufacturing process. It can be summarized as follows:

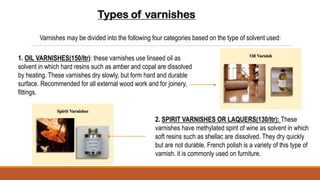

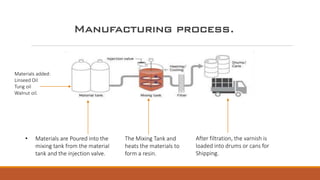

Varnish is a transparent protective coating made of a drying oil, resin, and solvent. Common components include linseed oil, resins like amber and copal, and solvents like turpentine. The manufacturing process involves heating materials in a mixing tank to form a resin, then filtering and packaging the varnish. Varnishes enhance wood grain while protecting surfaces from damage by water, abrasion and other environmental factors.

![Classification of varnishes

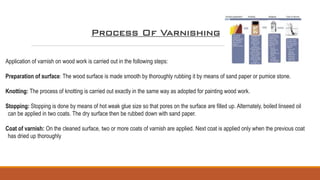

Natural resin varnishes

Modified natural resin varnishes

Synthetic resin varnish

NATURAL RESIN VARNISHES:

>Body consisting of natural resin derived from certain trees. Natural resin from live trees

or fossils[which are superior].

>Resins soluble in an oil mixture warmed to temperature [500-600f] based on the

quantity of gloss needed.

> Oil and mineral resin lacquer

> Dryers used in varnish are organic salts of iron , zinc to accelerate the oxidation and

hardenening of vehicle.

NATURAL RESIN VARNISHES](https://image.slidesharecdn.com/materialstudyvarnishes-220723210751-0f50a64d/85/MATERIAL-STUDY-_-Varnishes-pptx-11-320.jpg)