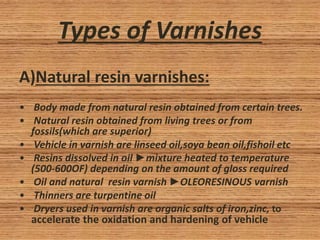

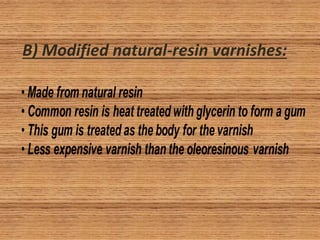

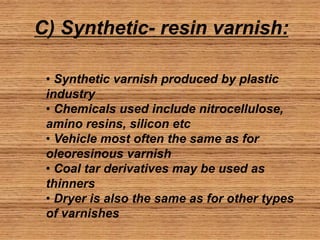

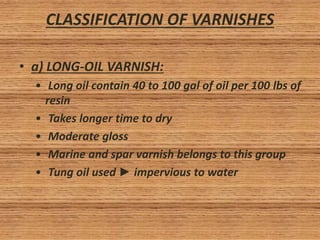

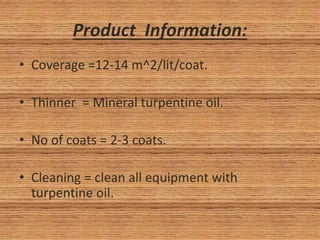

The document provides a detailed overview of varnishes, describing their characteristics, advantages, and various types including natural resin, modified natural resin, and synthetic varnish. It also categorizes varnishes based on oil content—long, medium, and short—and outlines suitable environments and preparation methods for applying varnish. Additionally, it includes product information regarding coverage, thinning, and cleaning procedures.