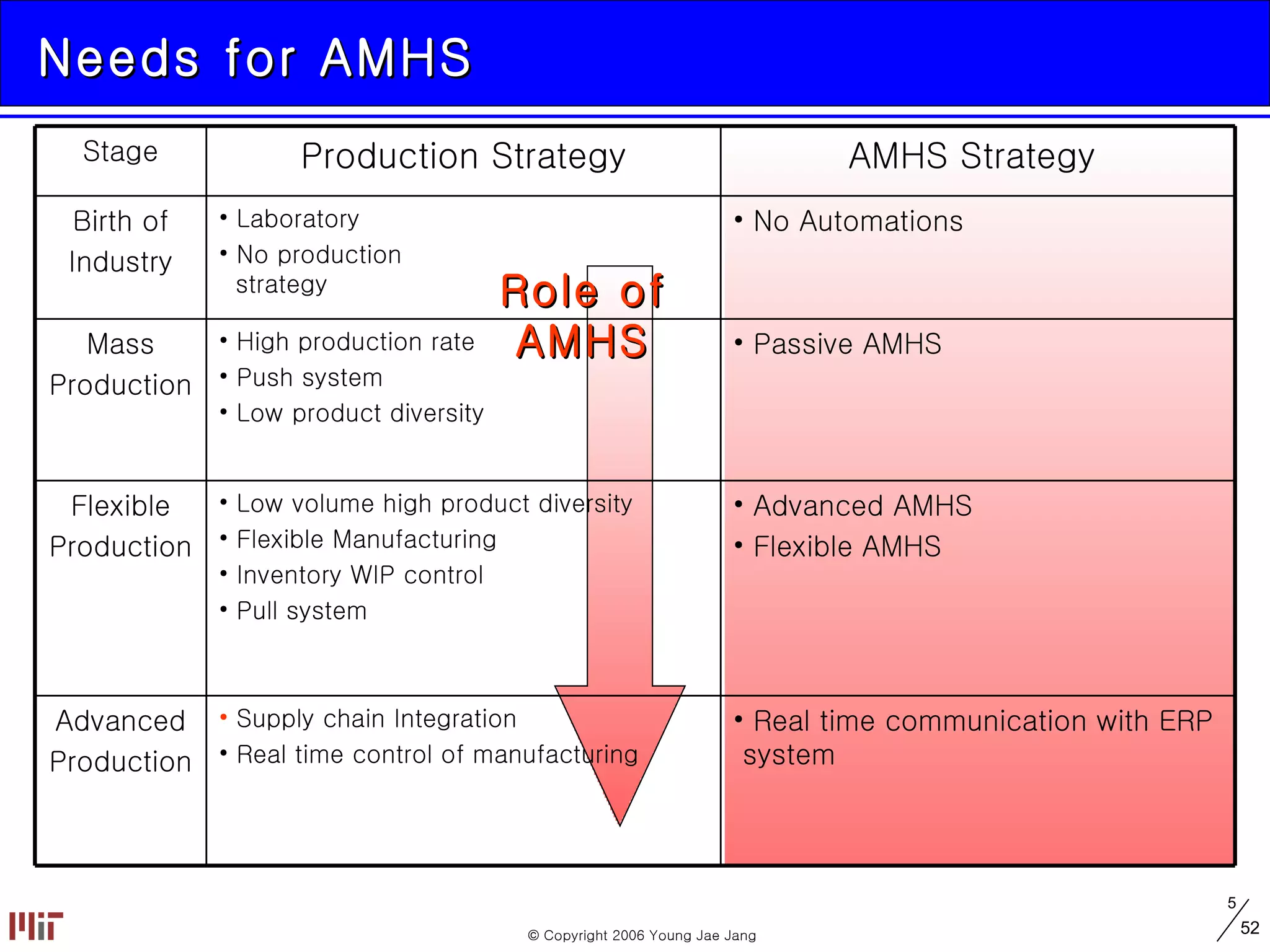

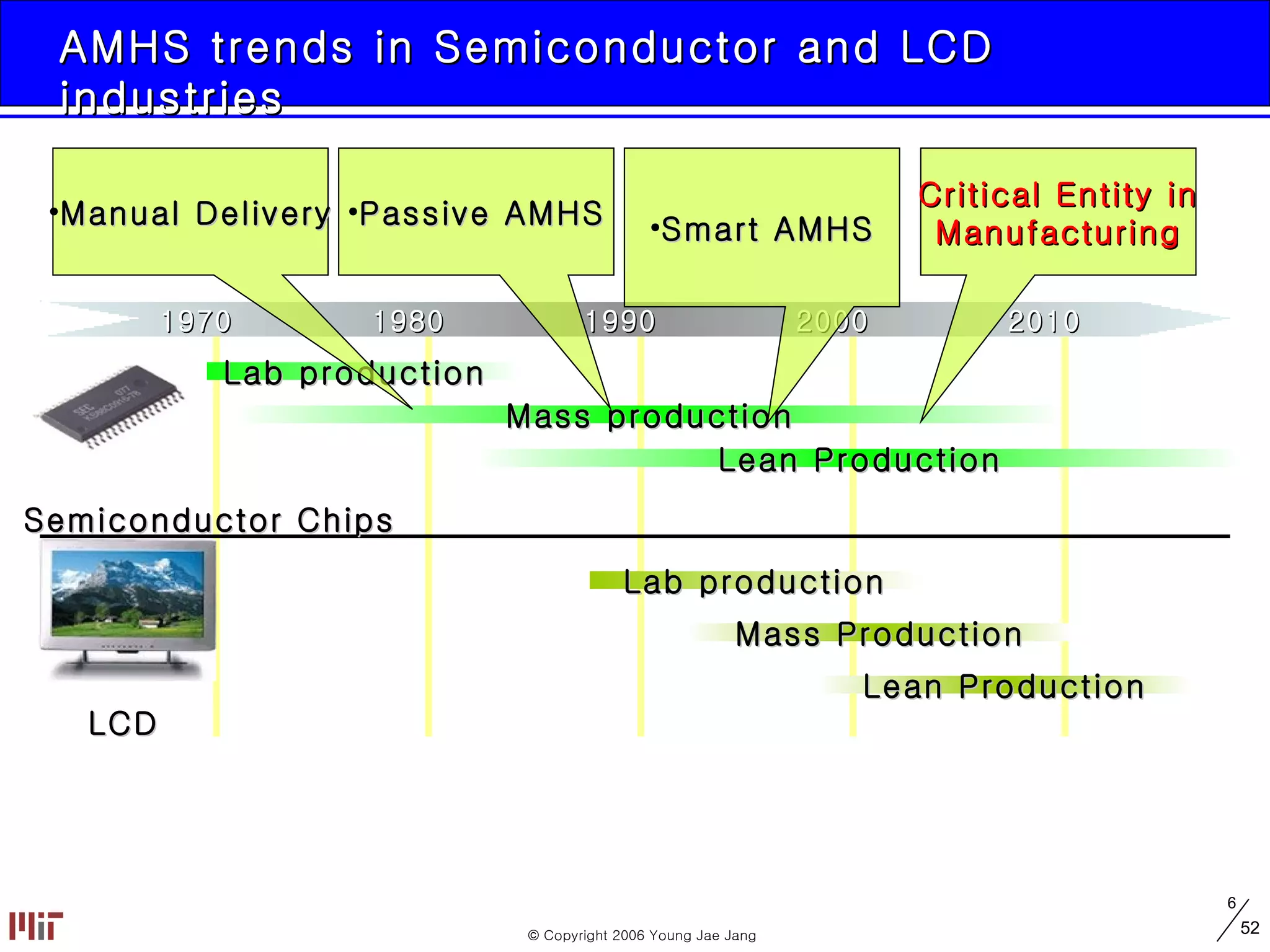

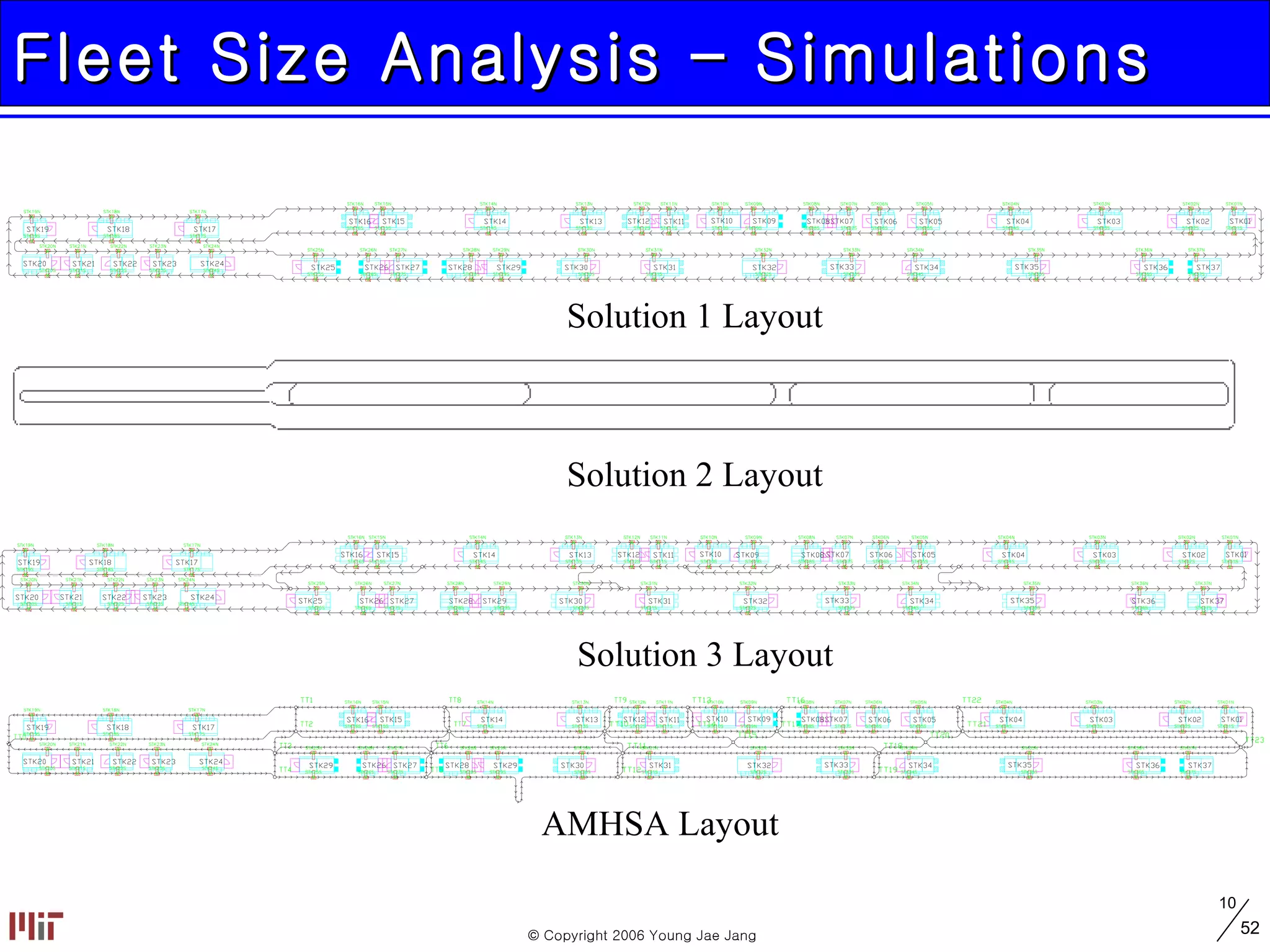

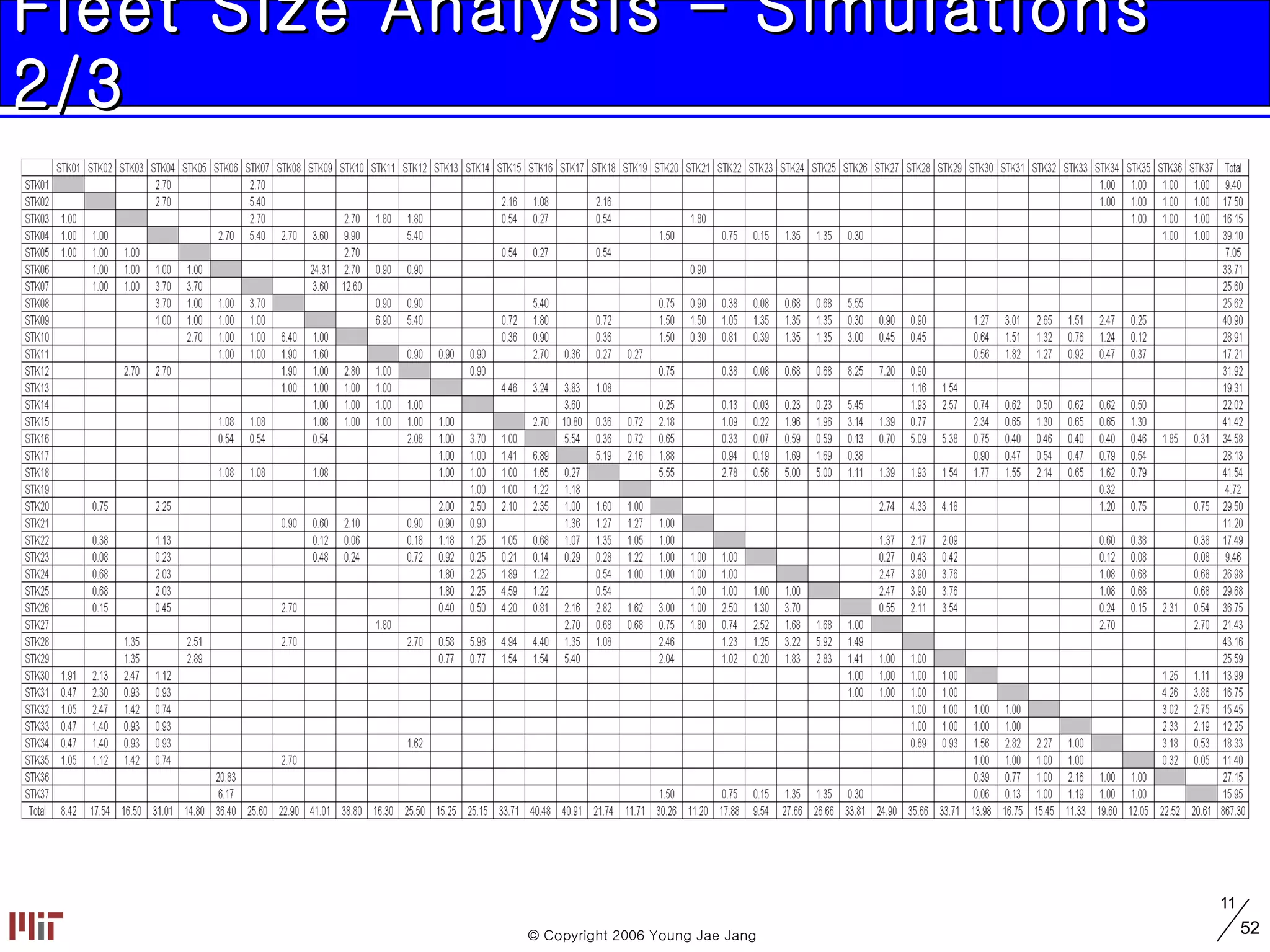

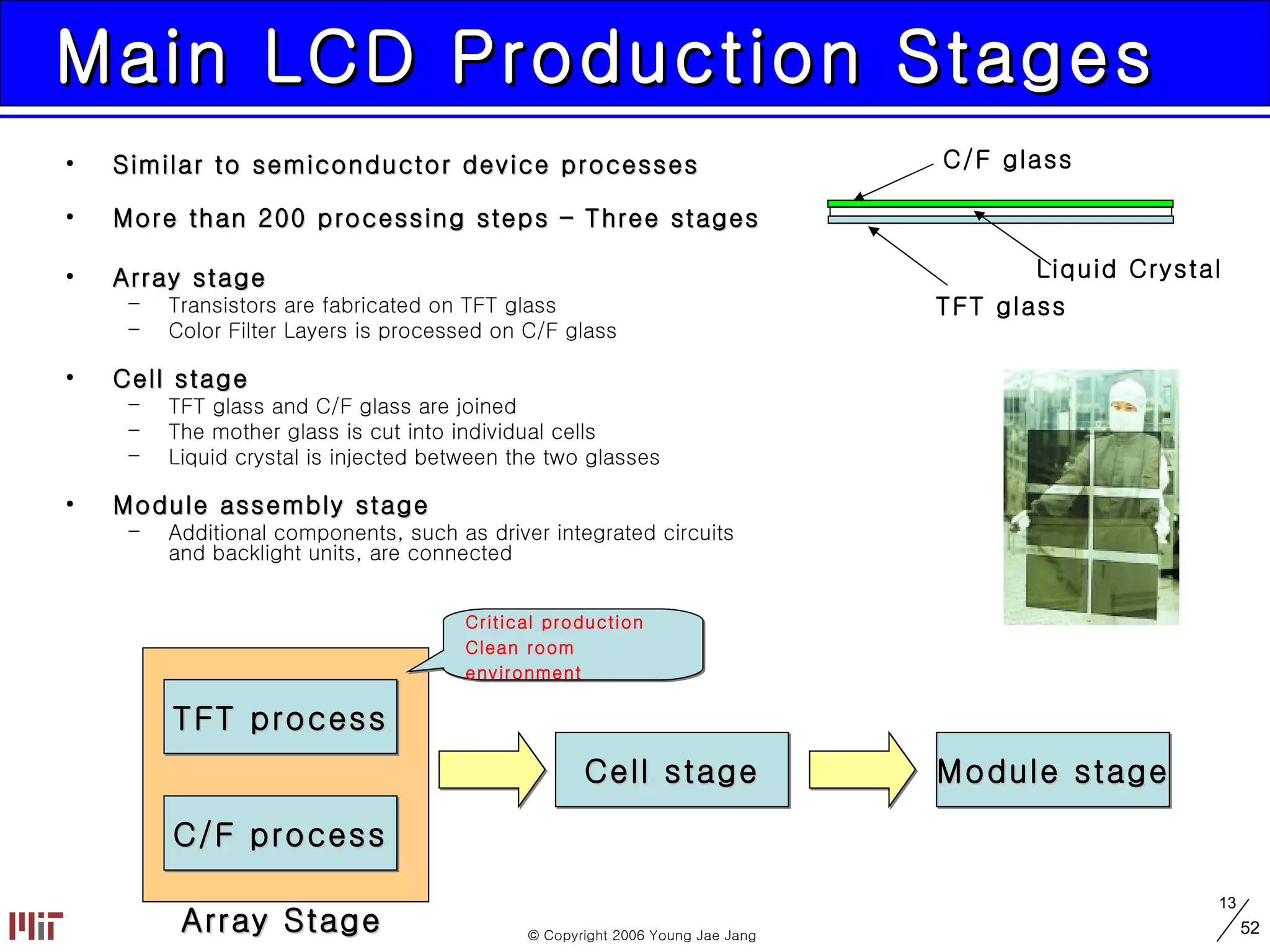

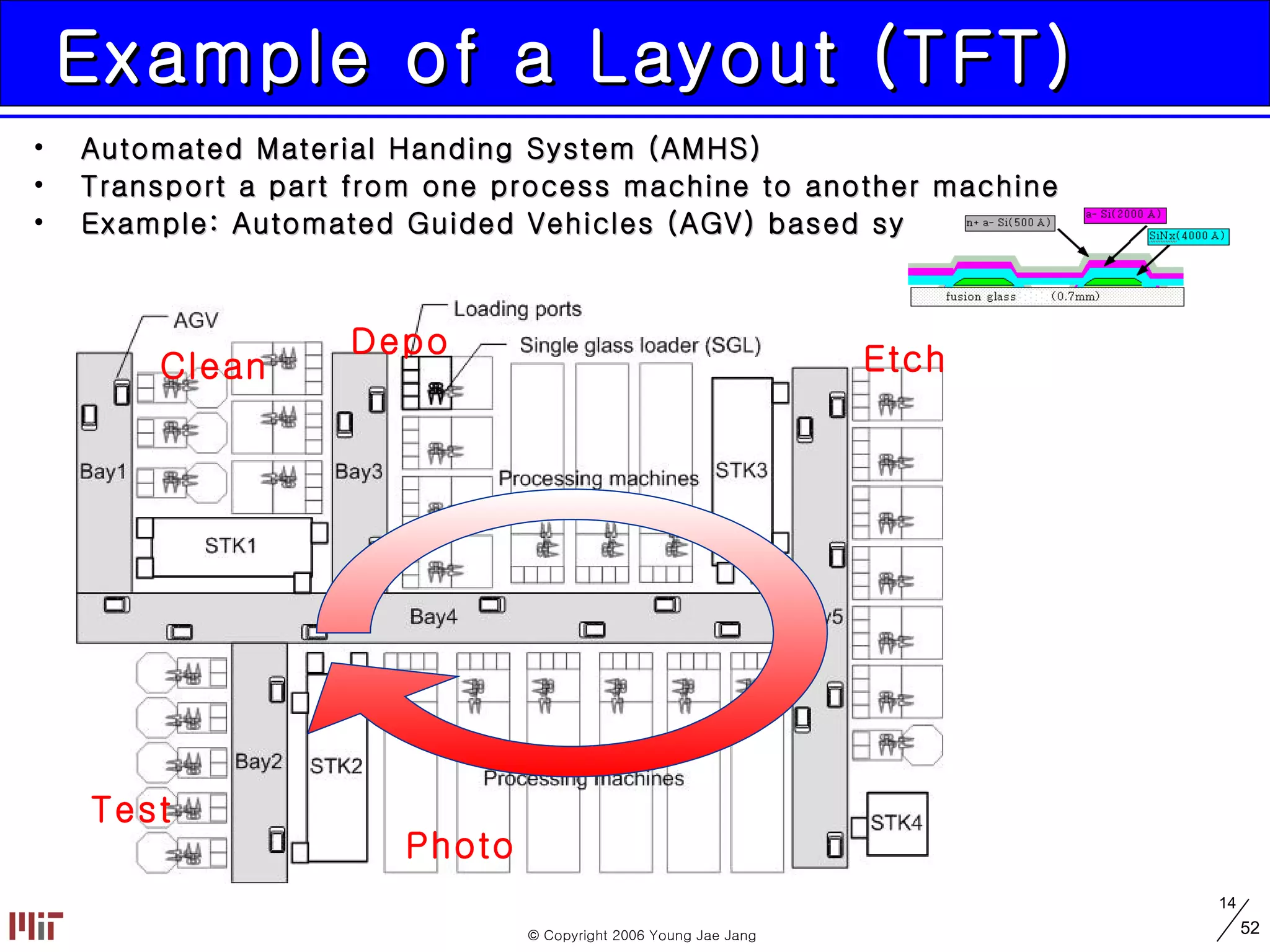

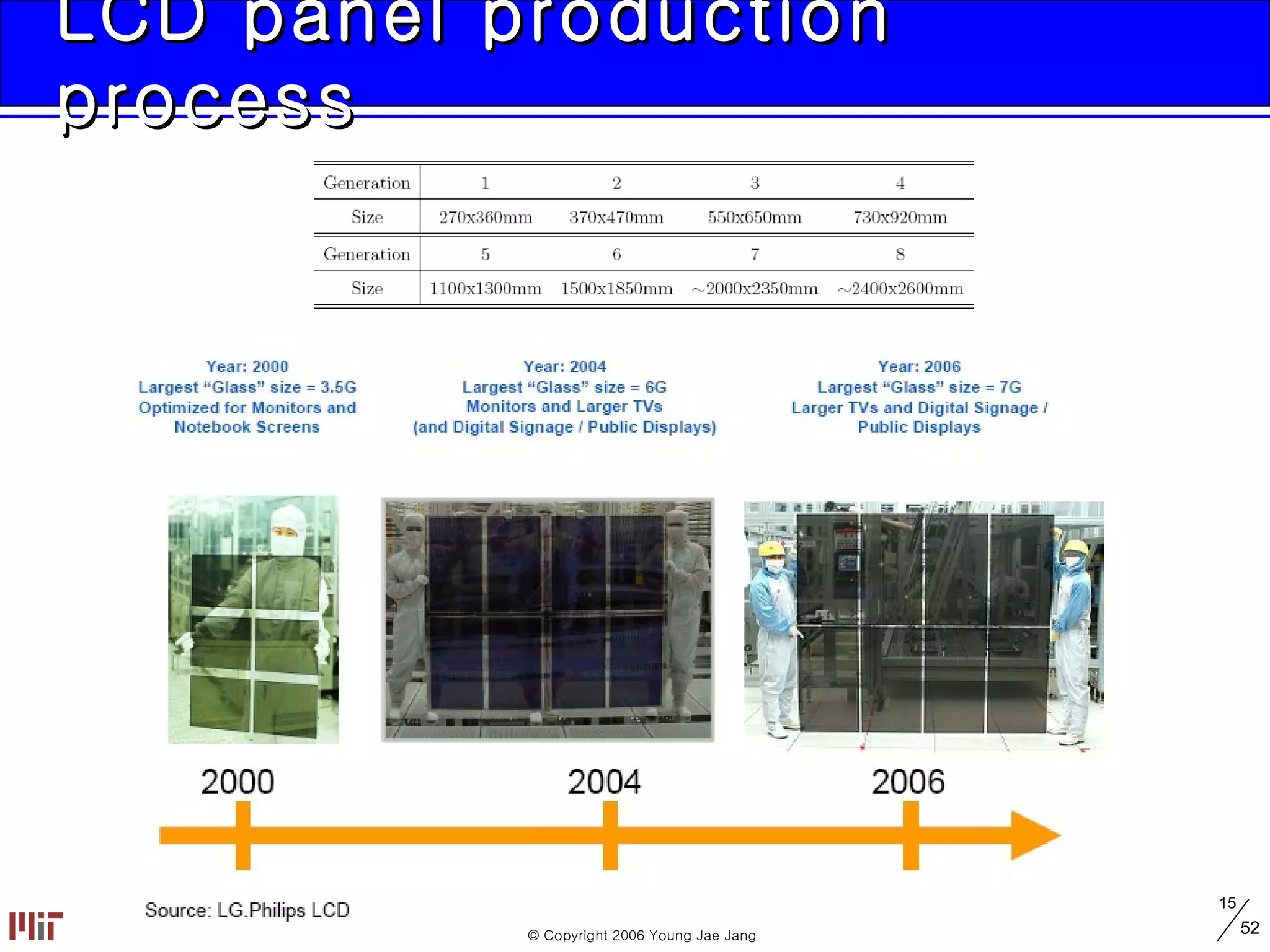

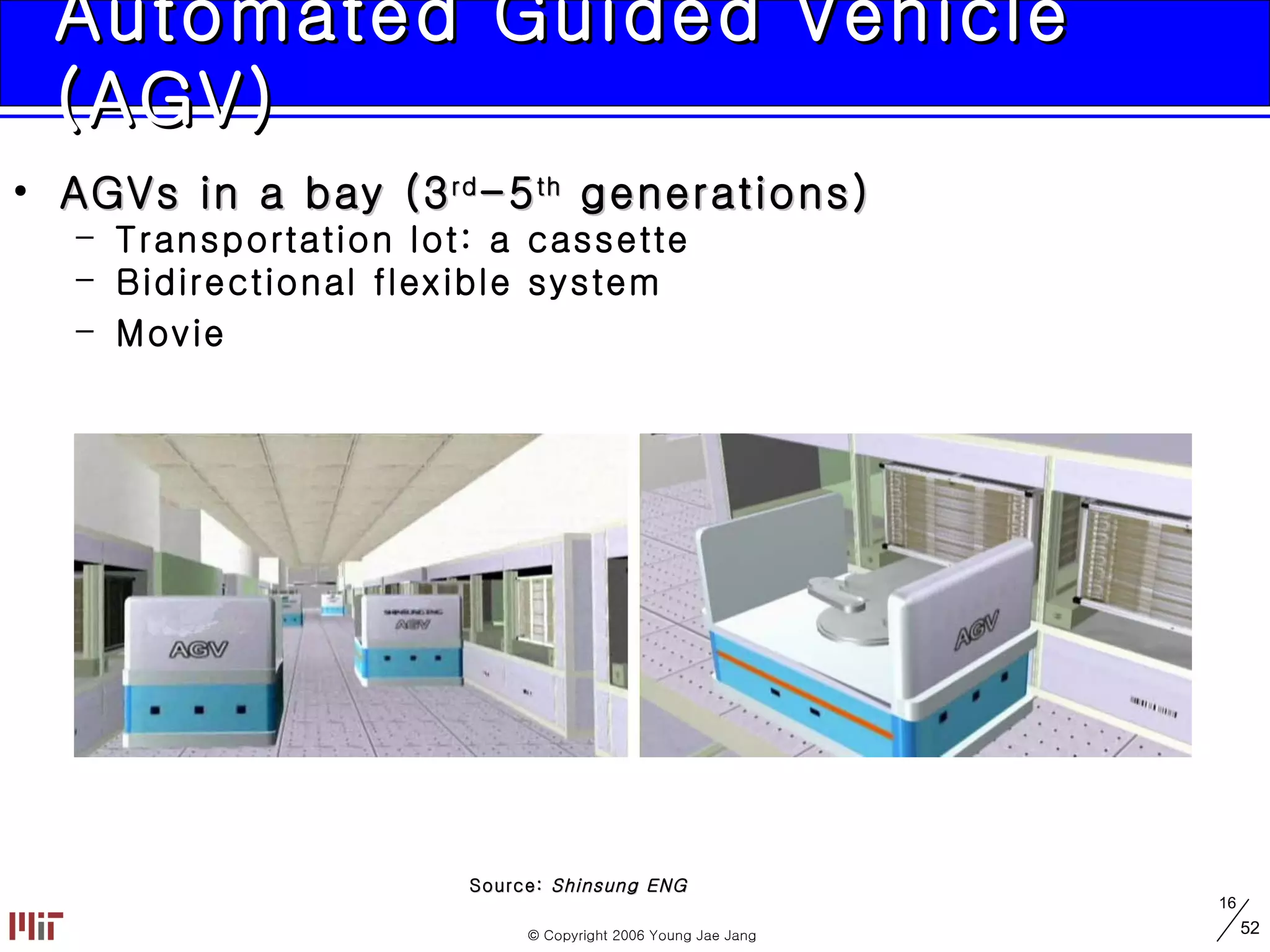

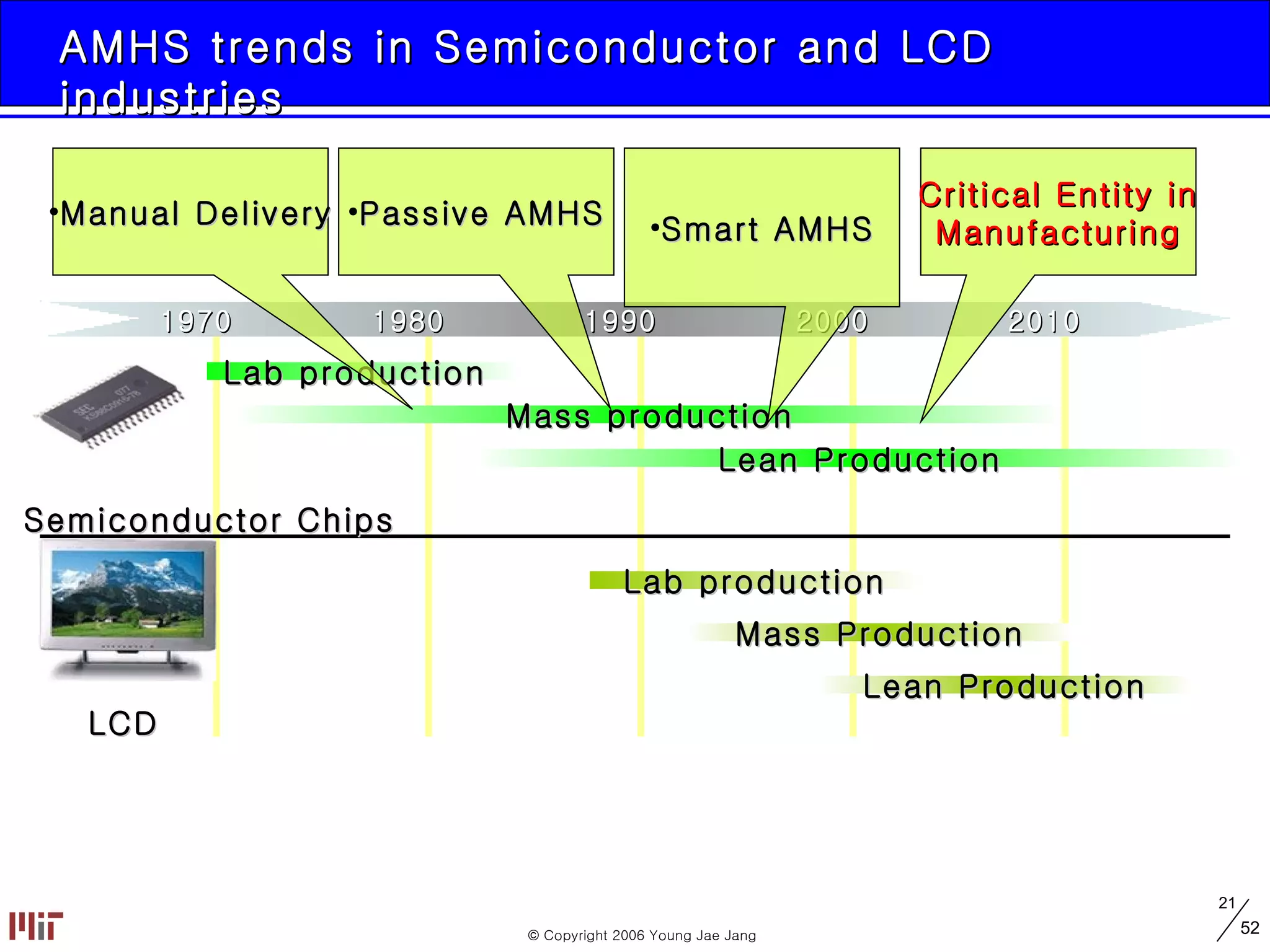

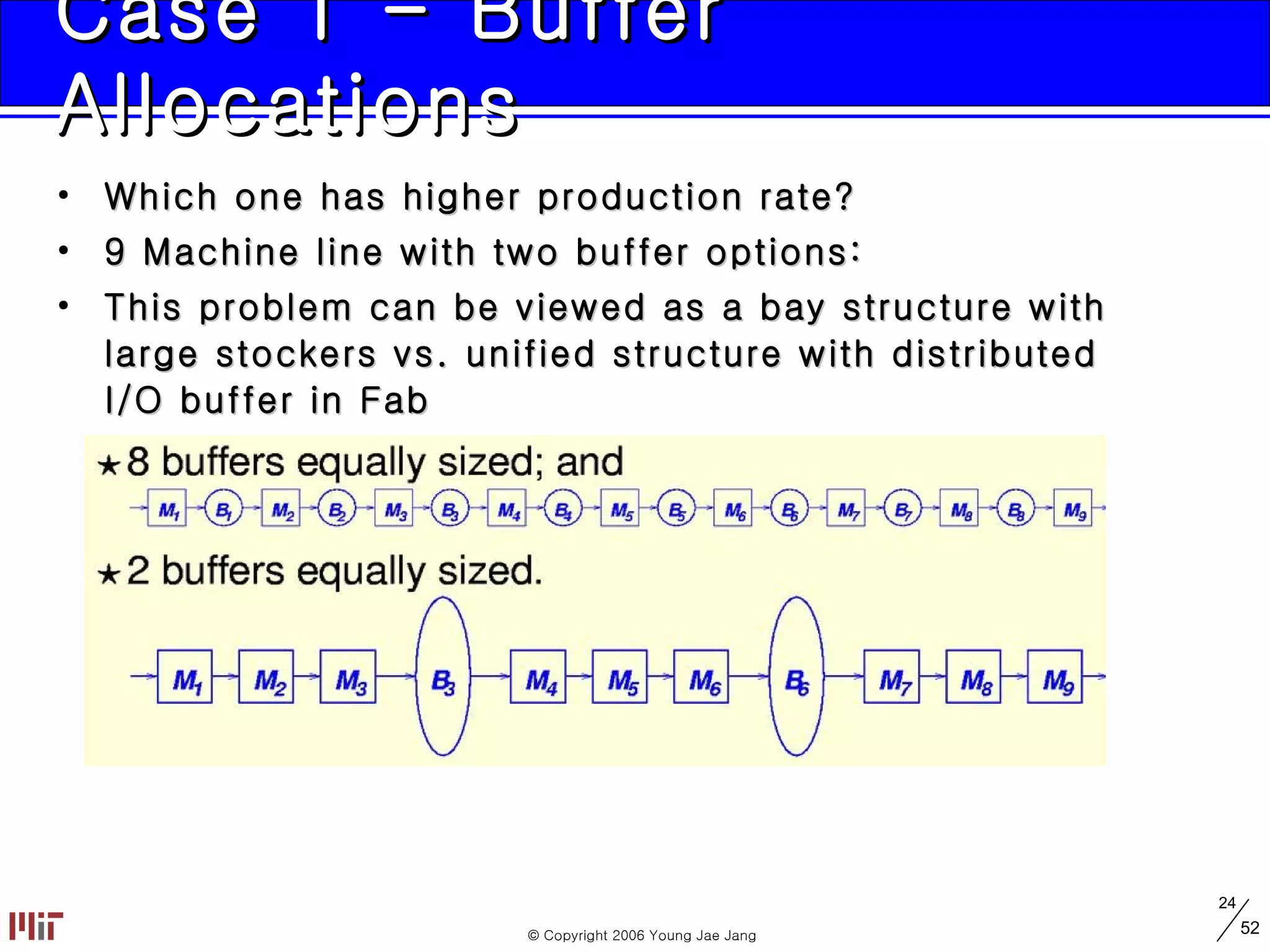

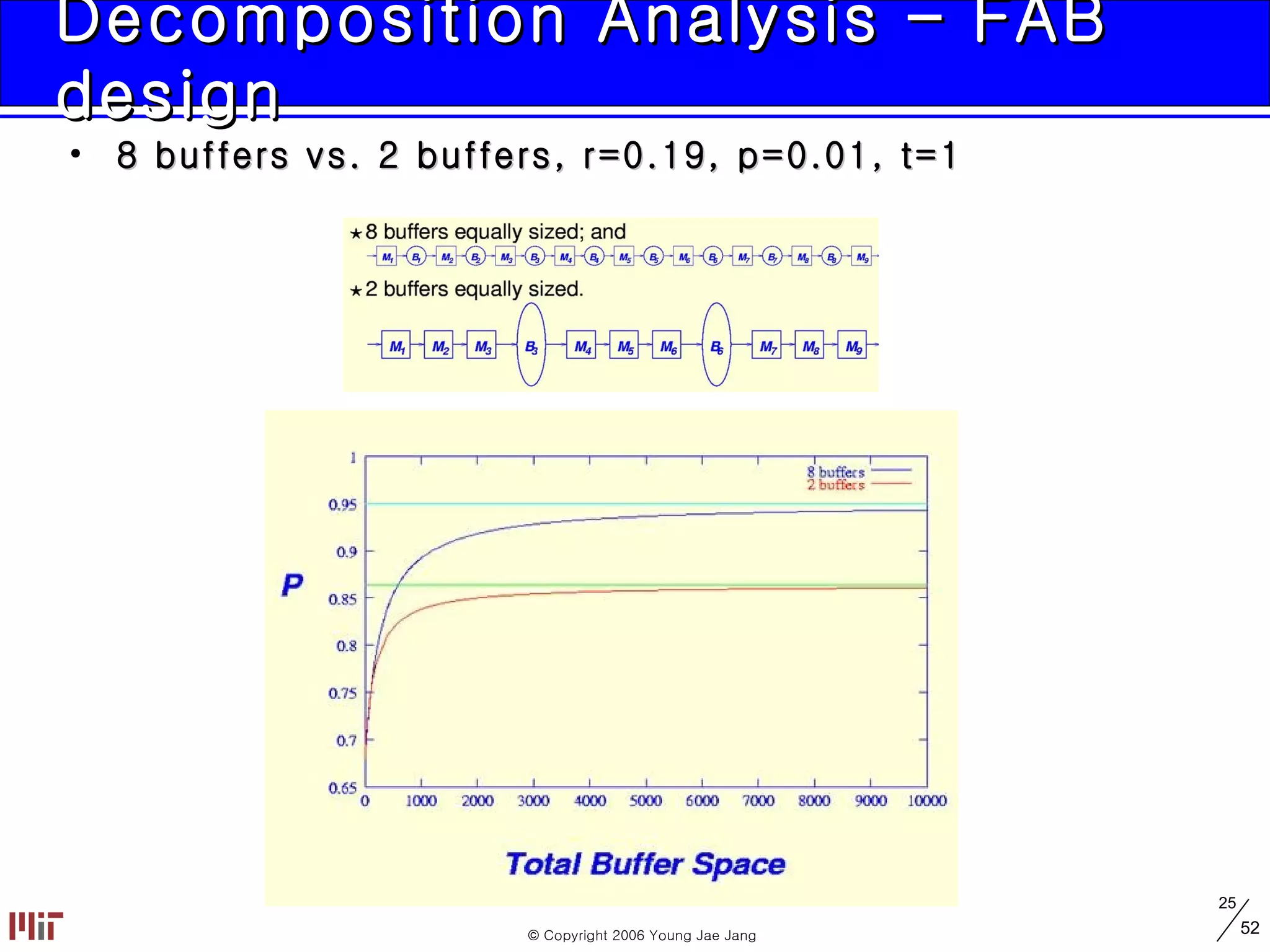

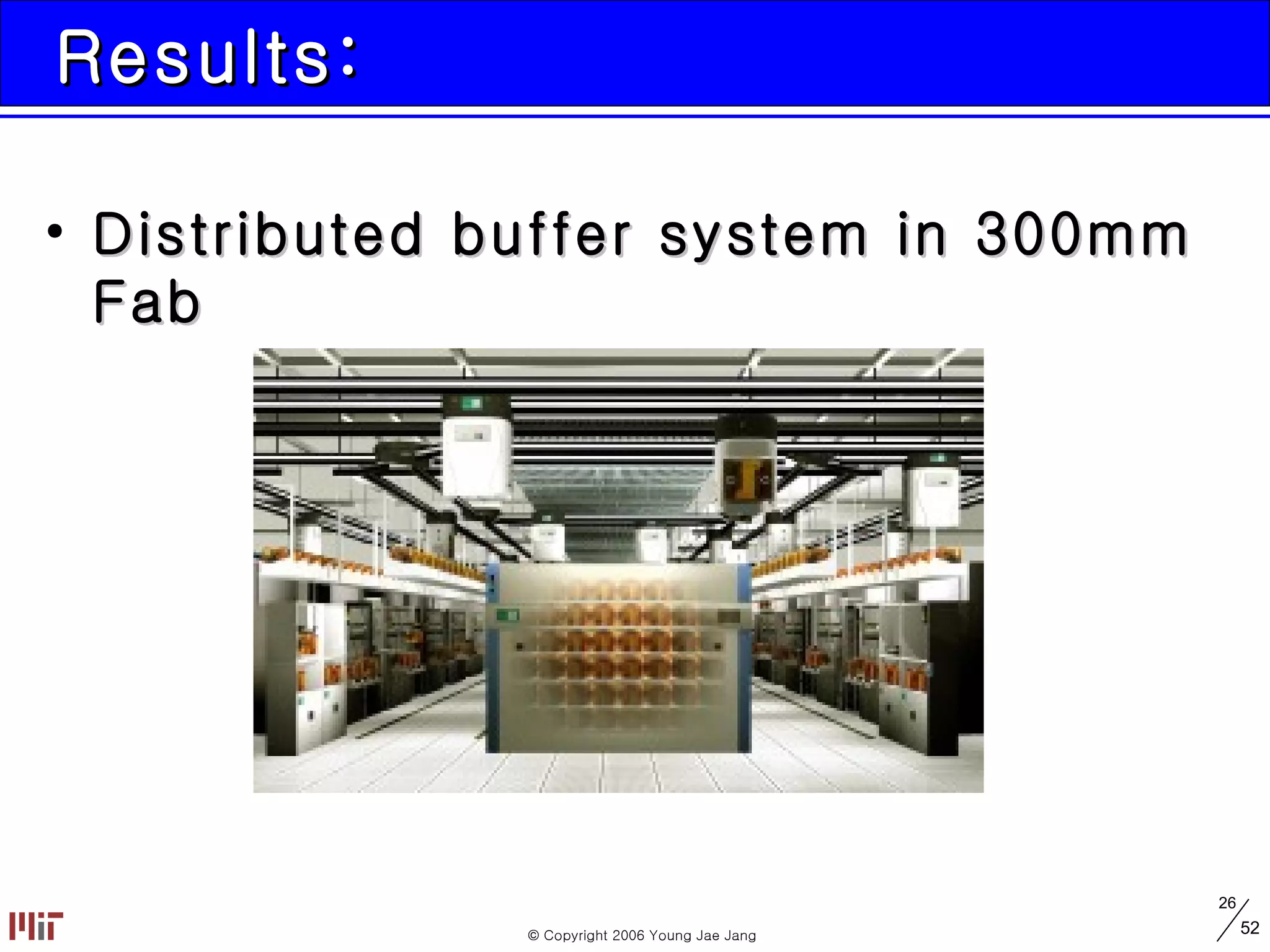

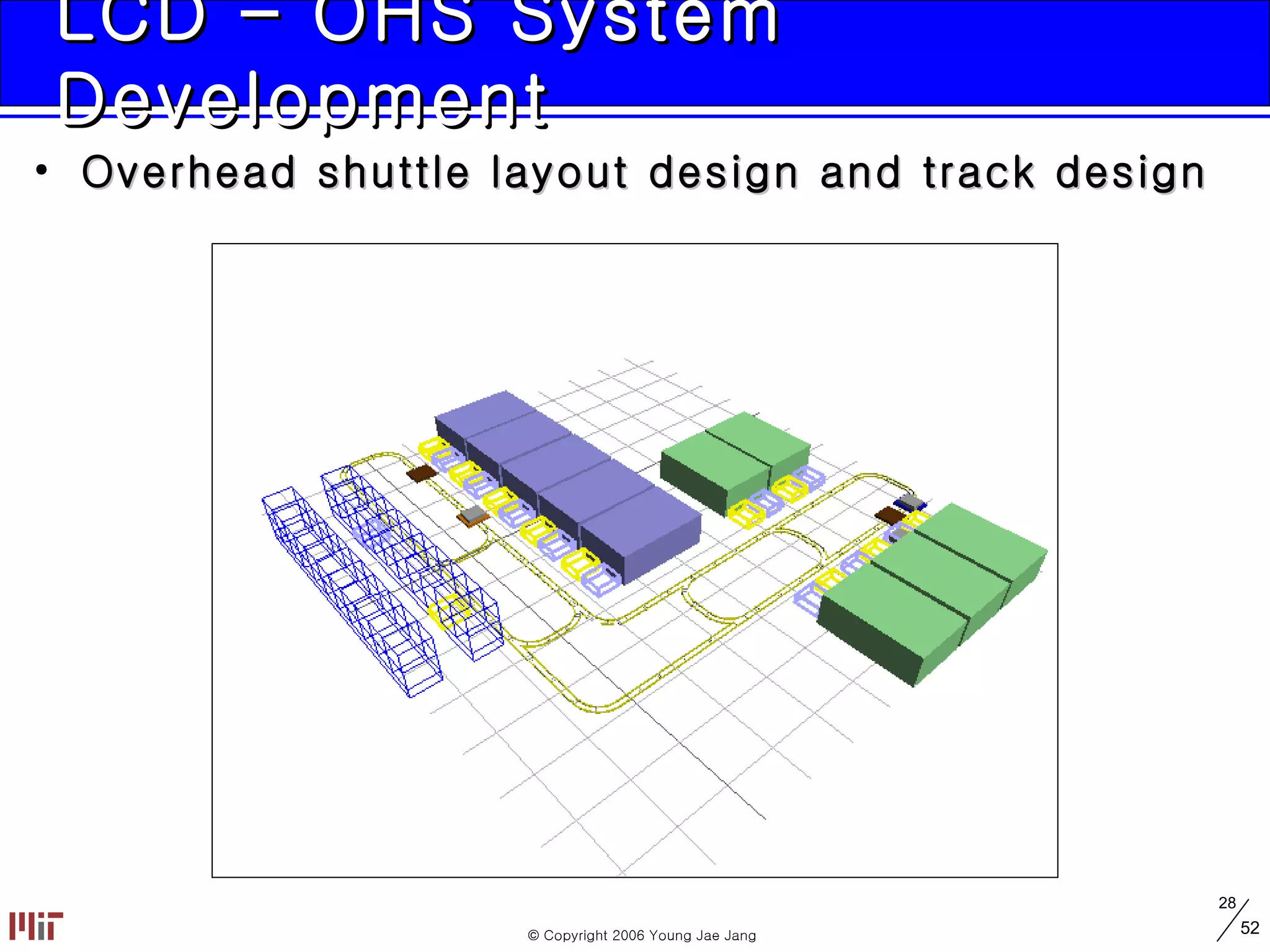

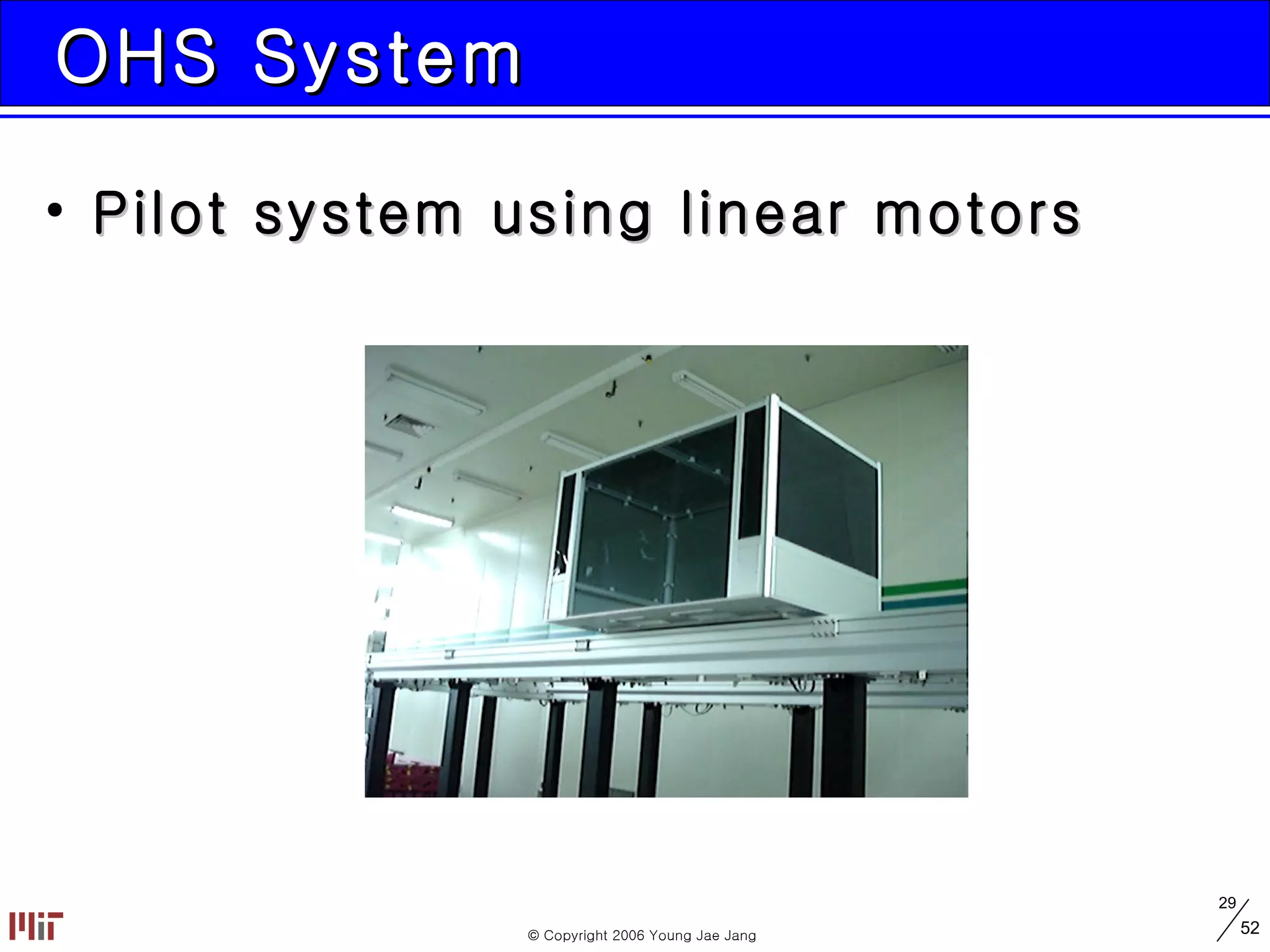

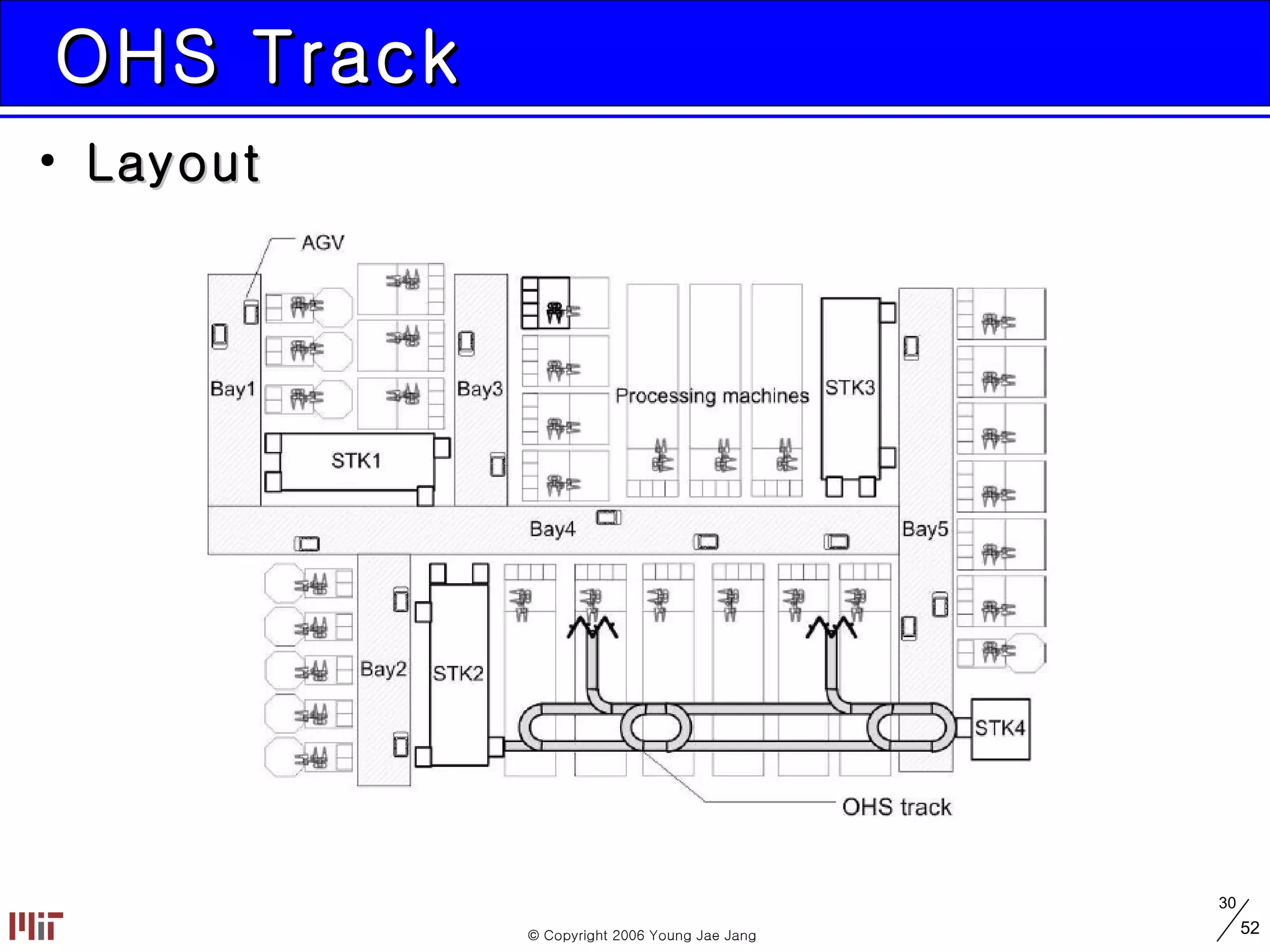

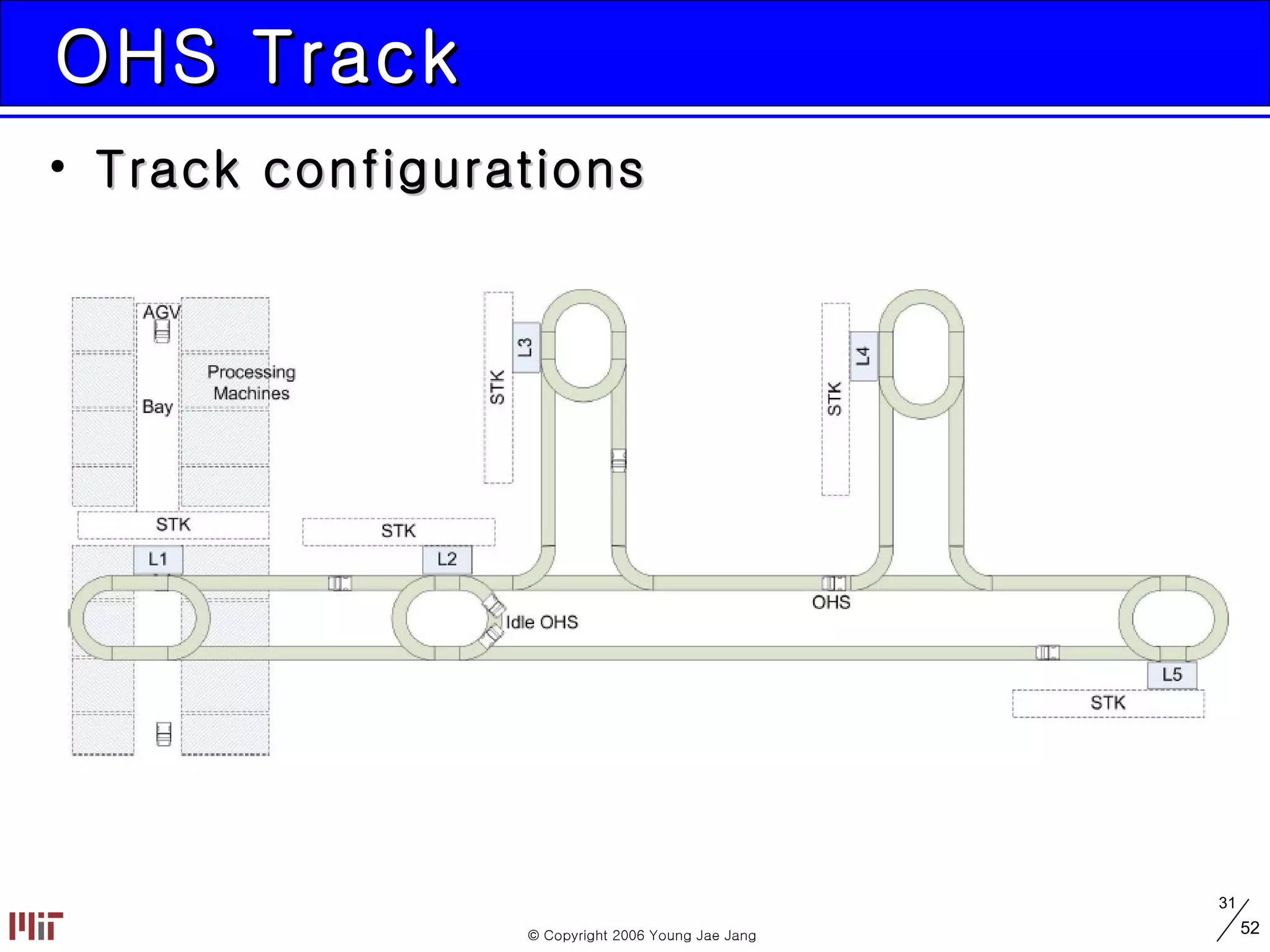

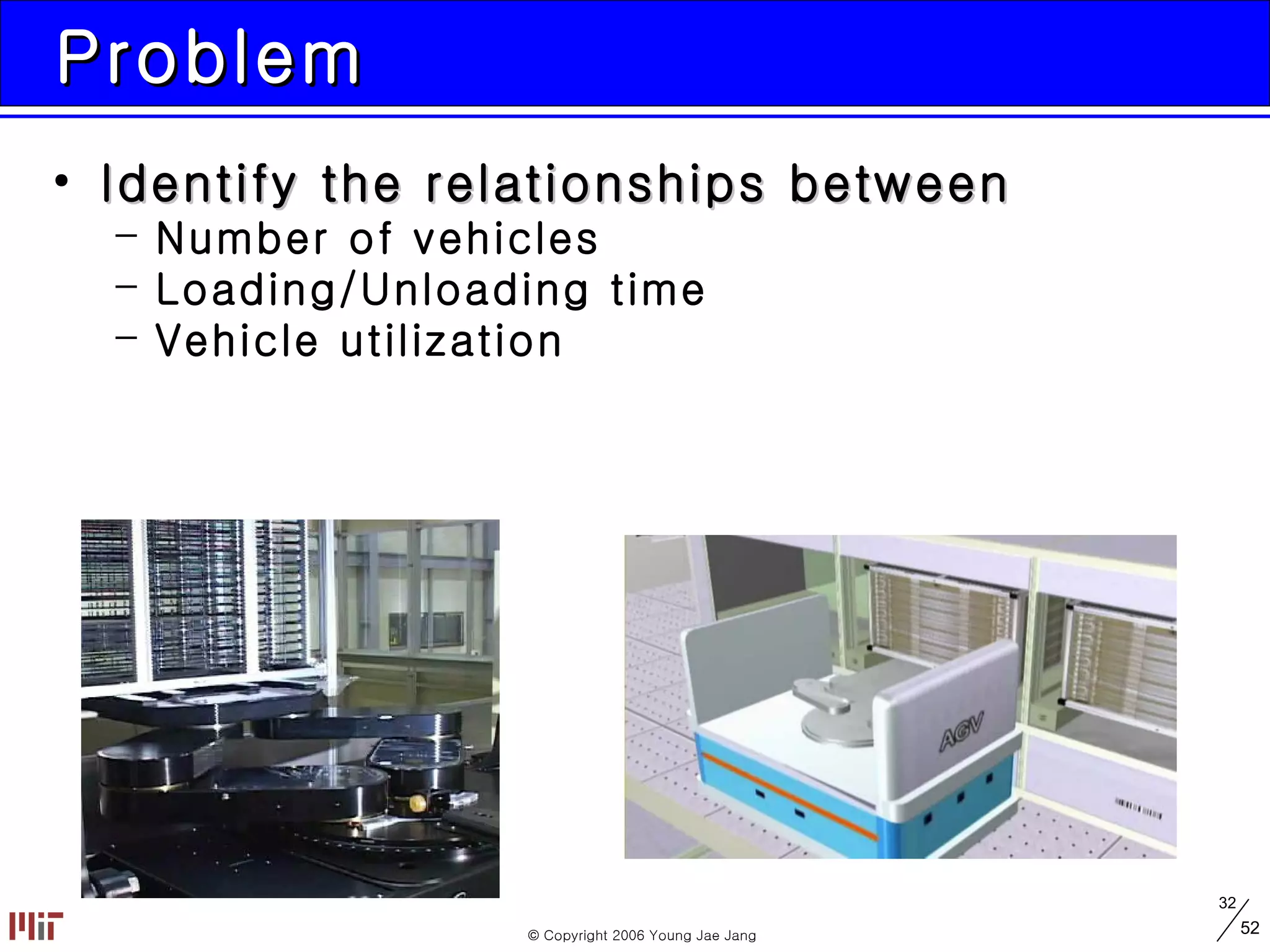

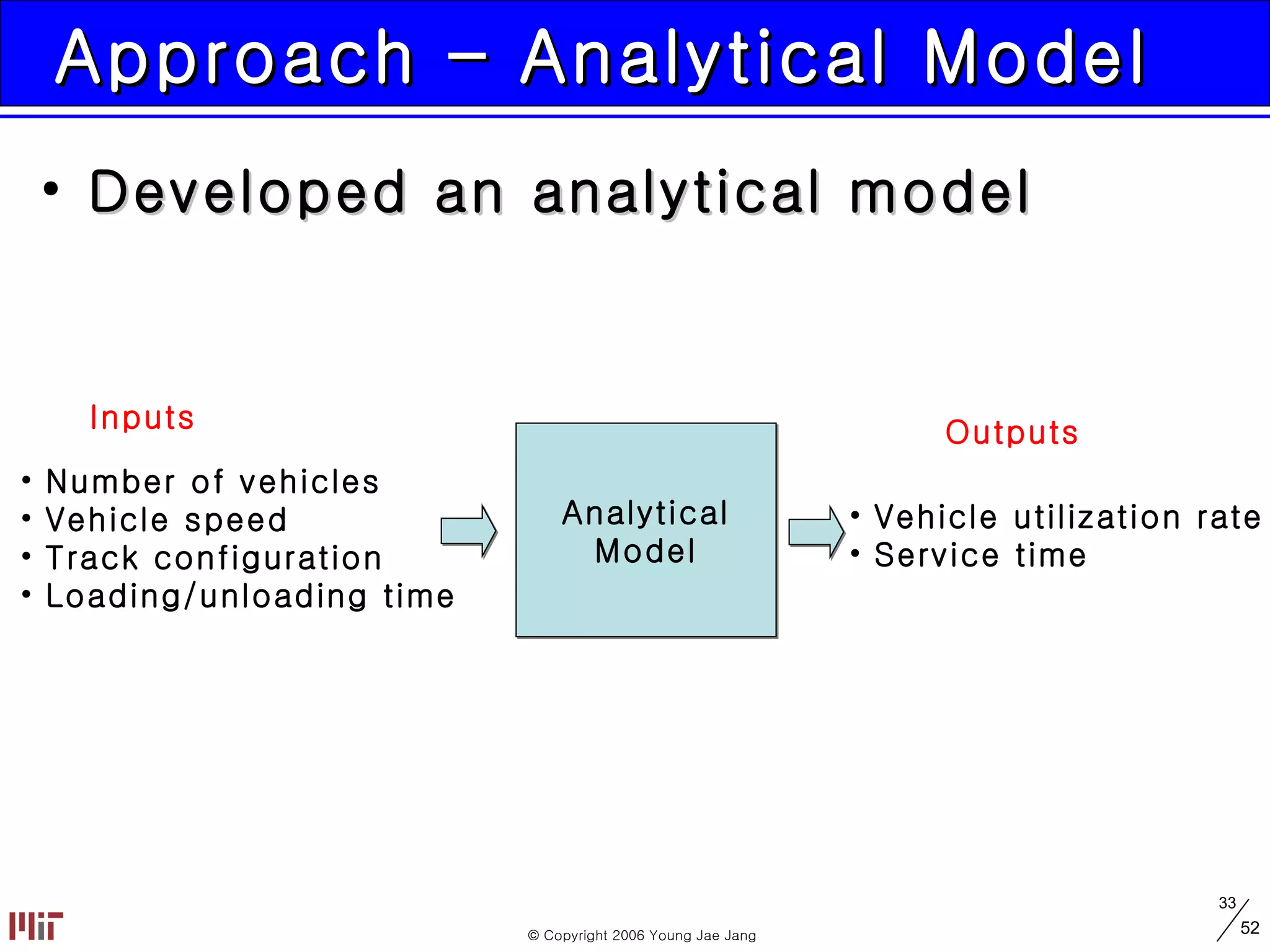

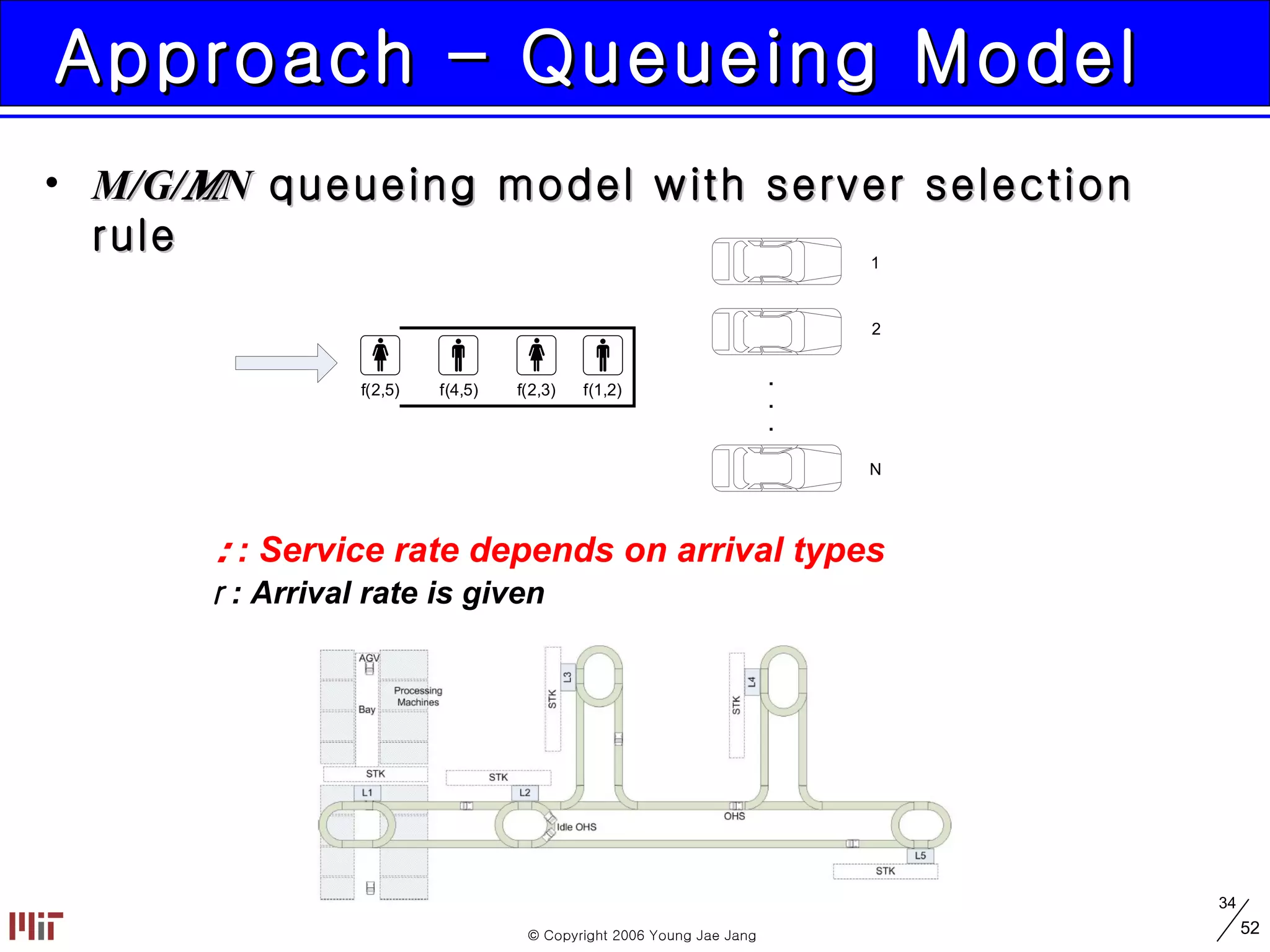

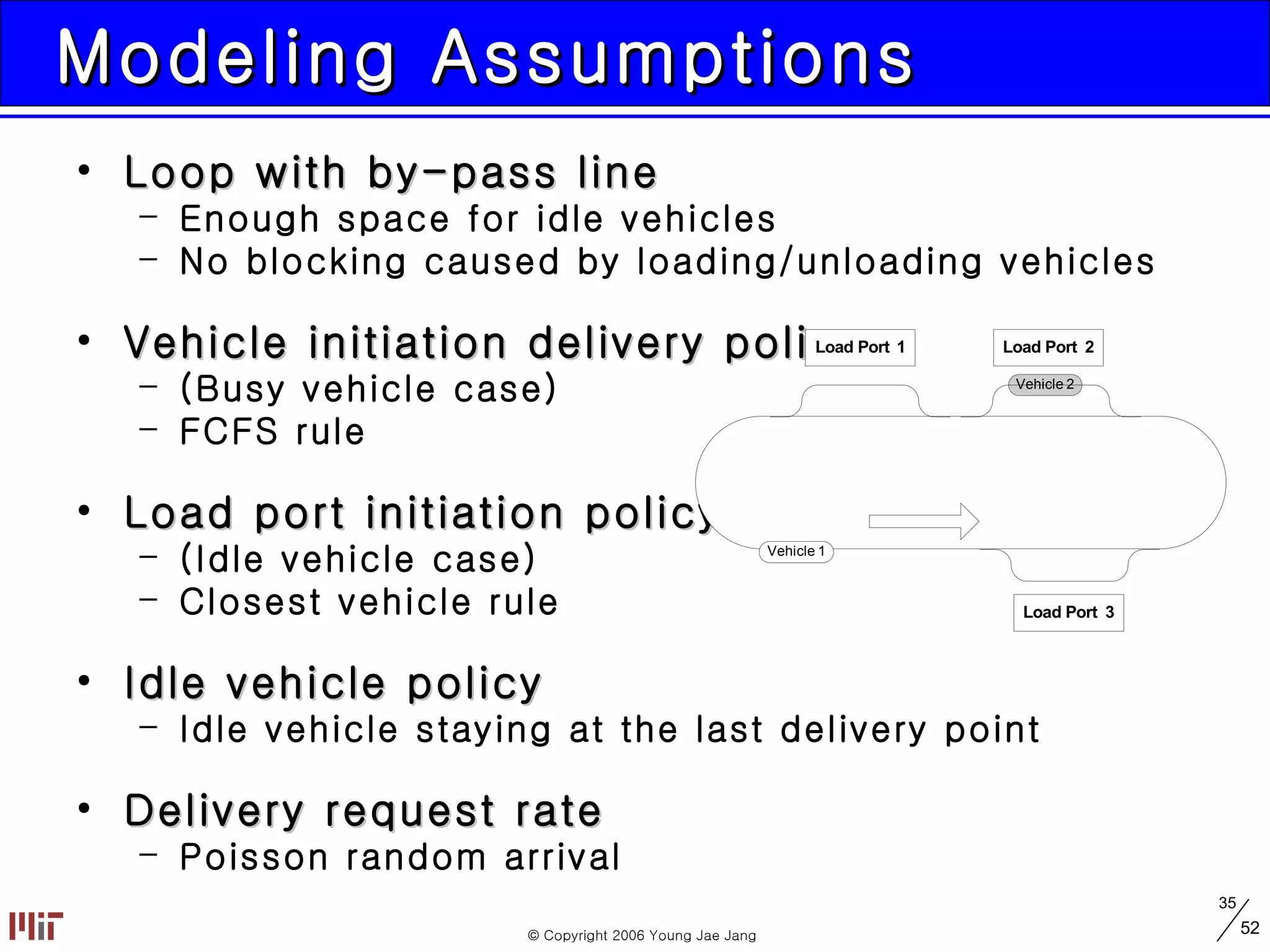

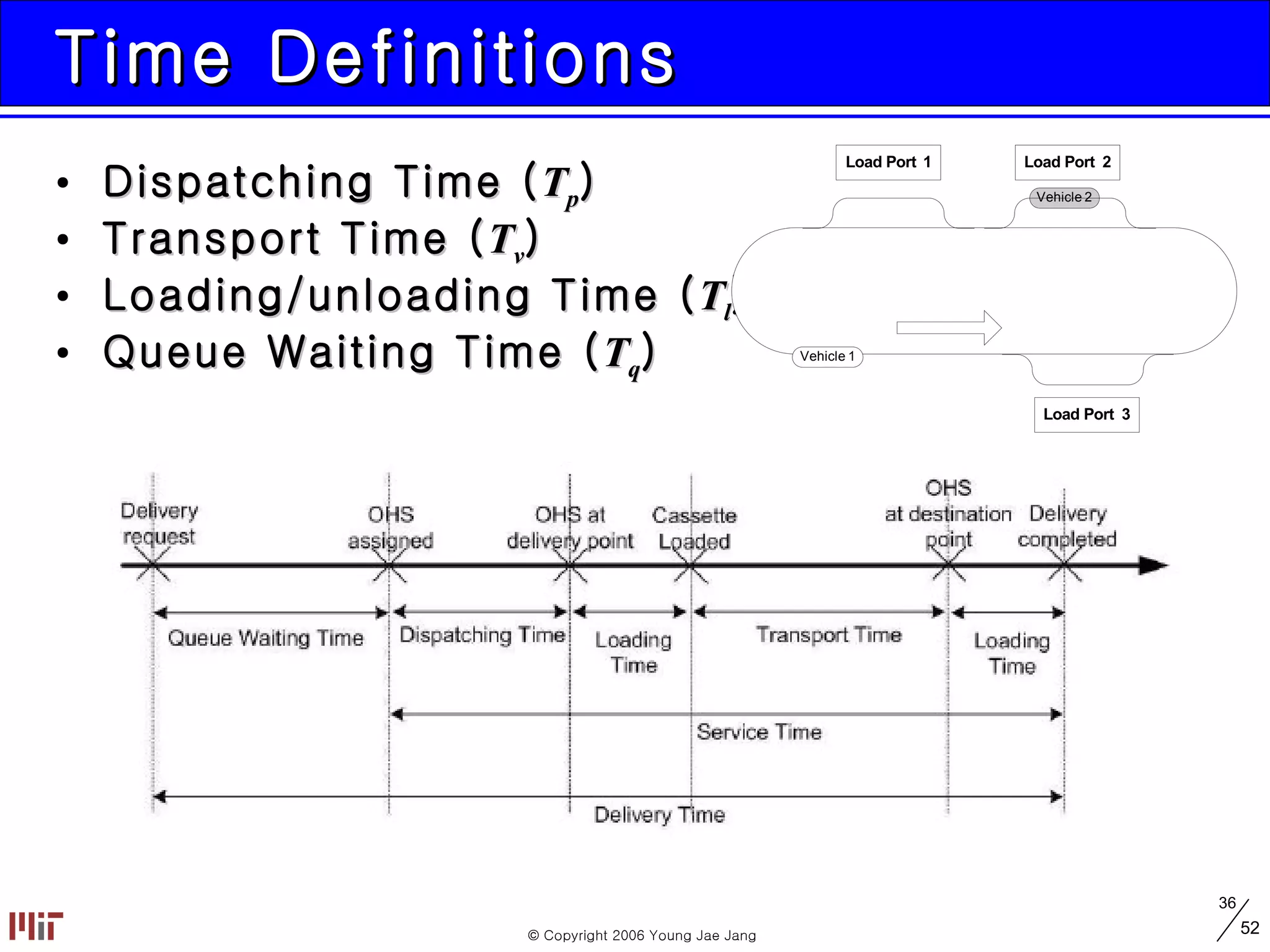

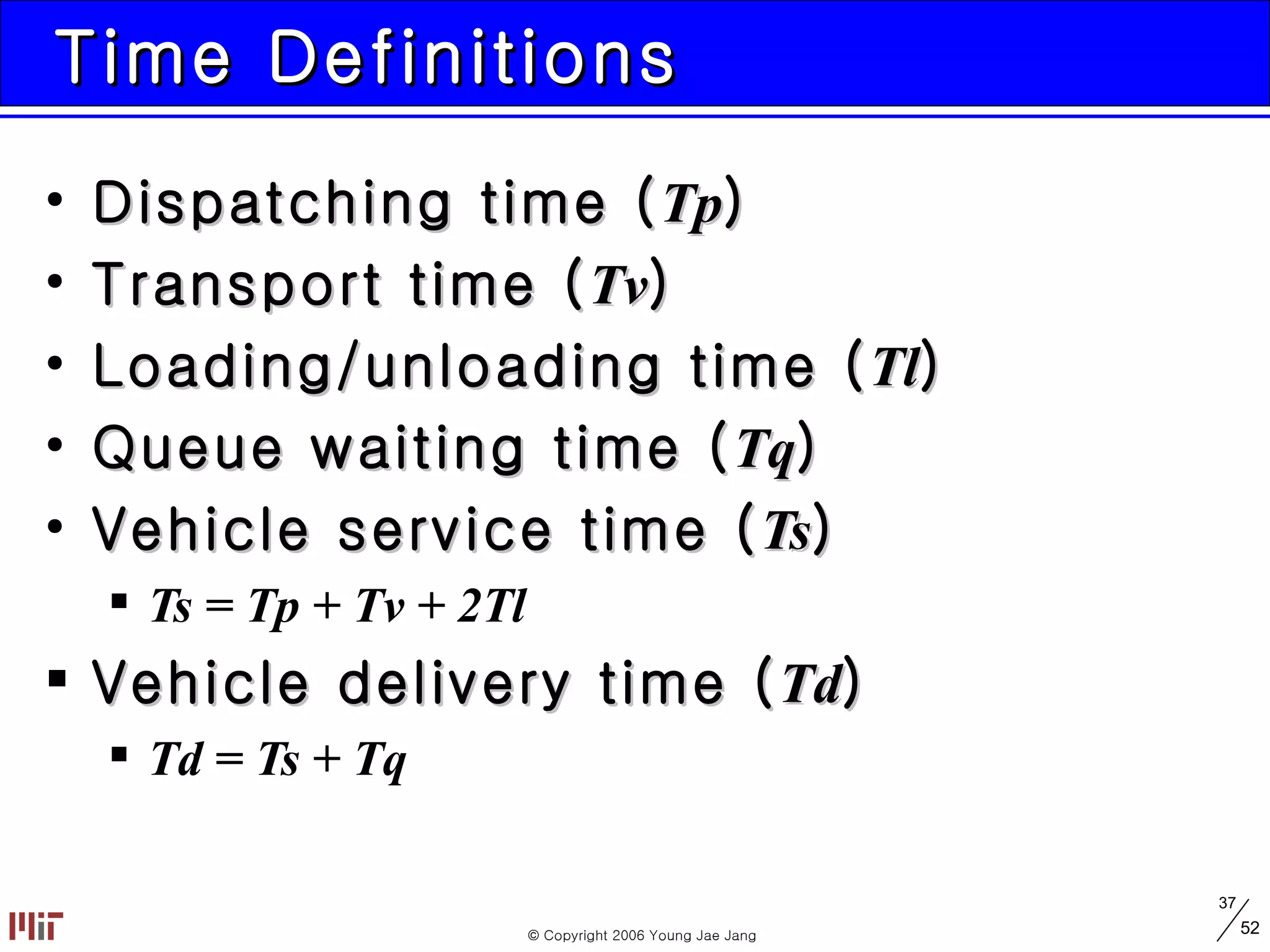

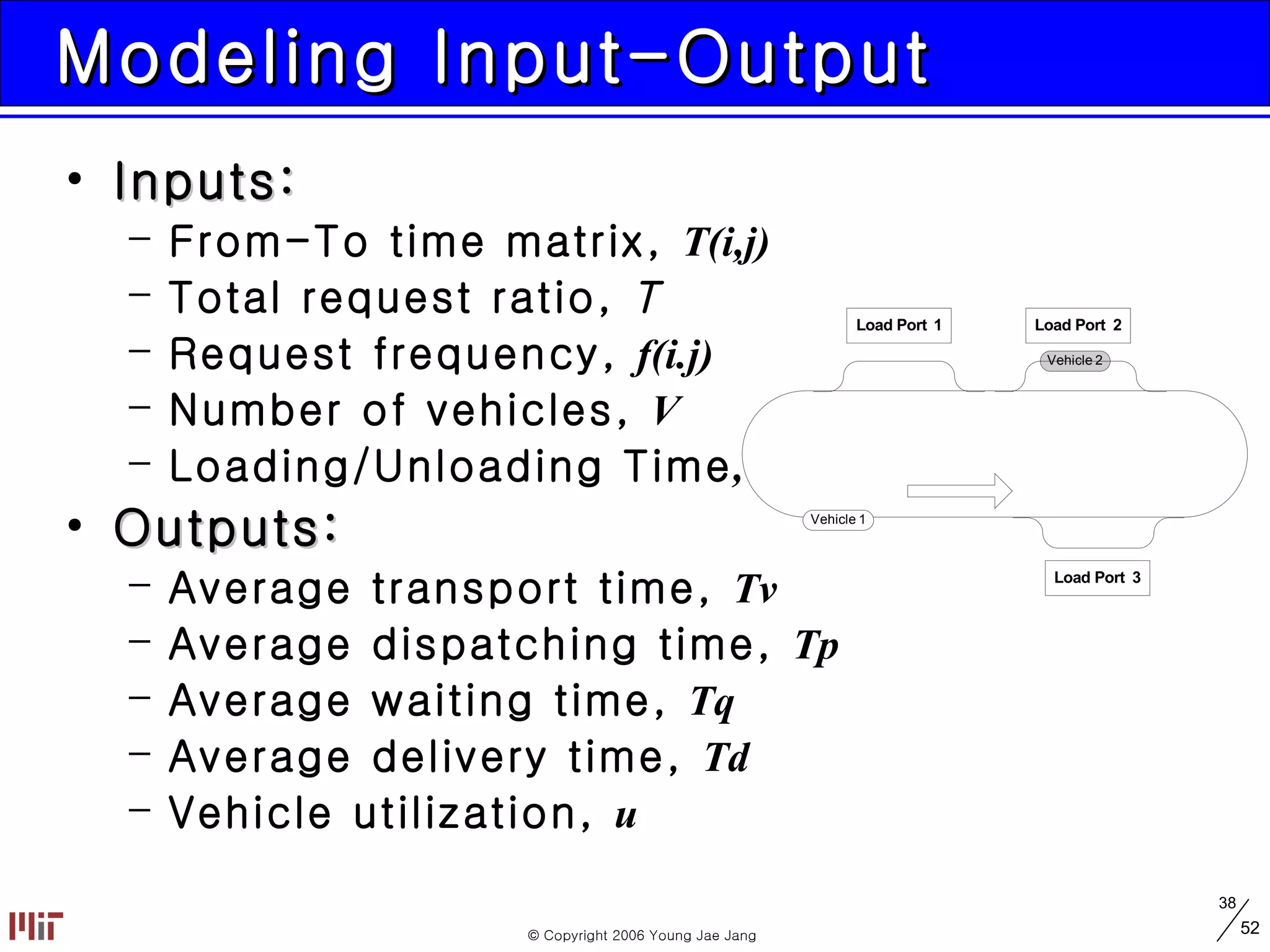

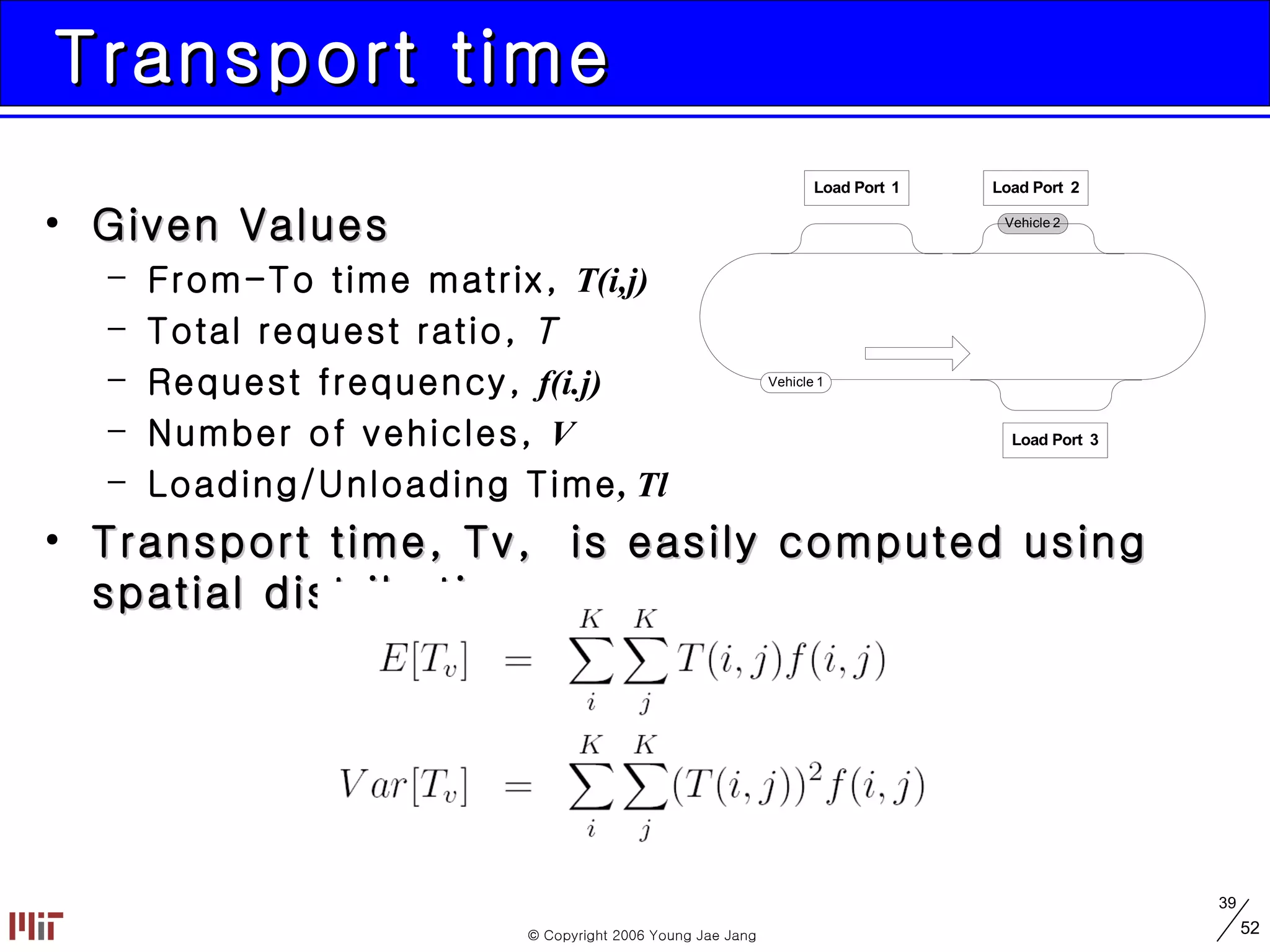

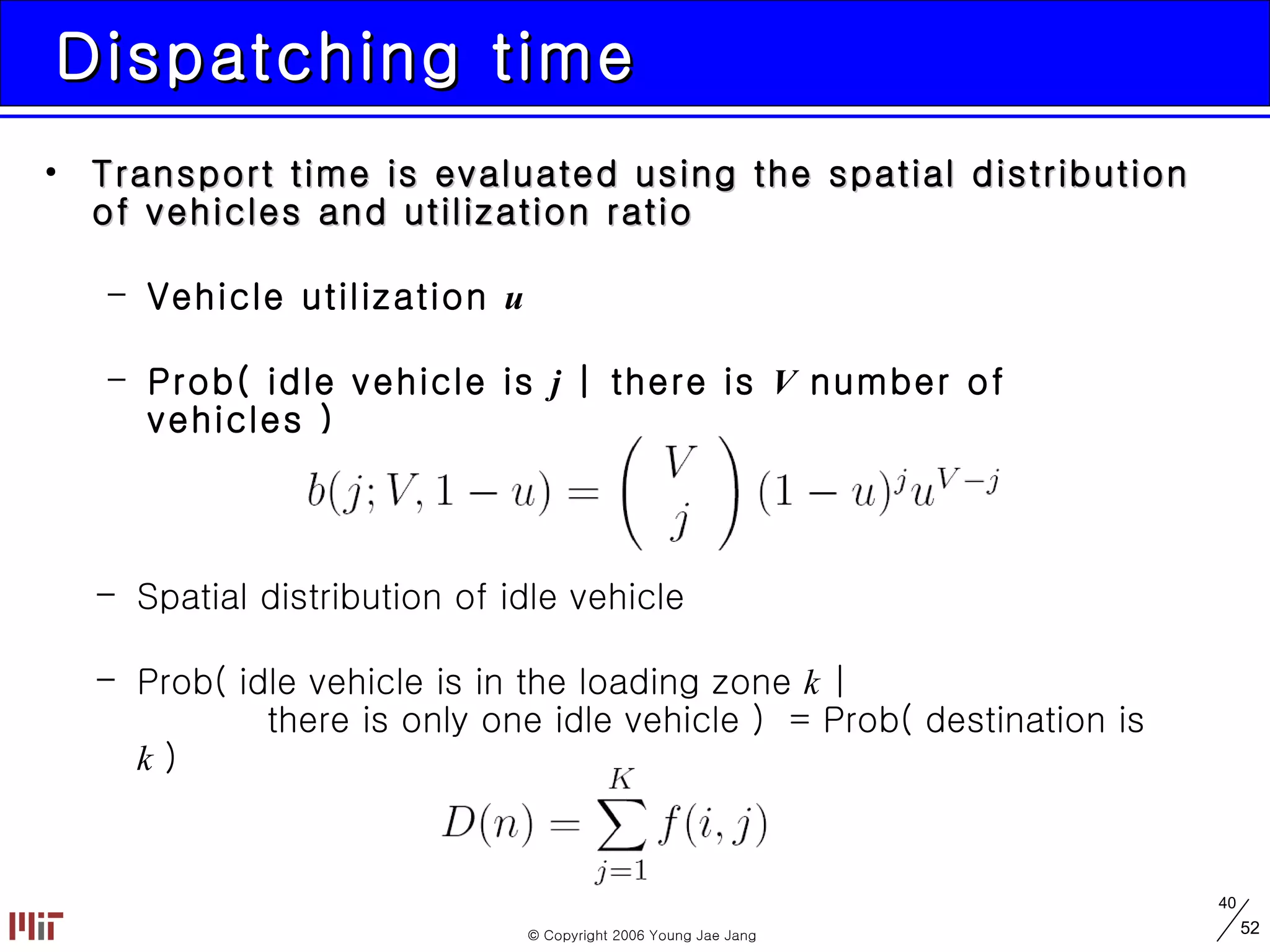

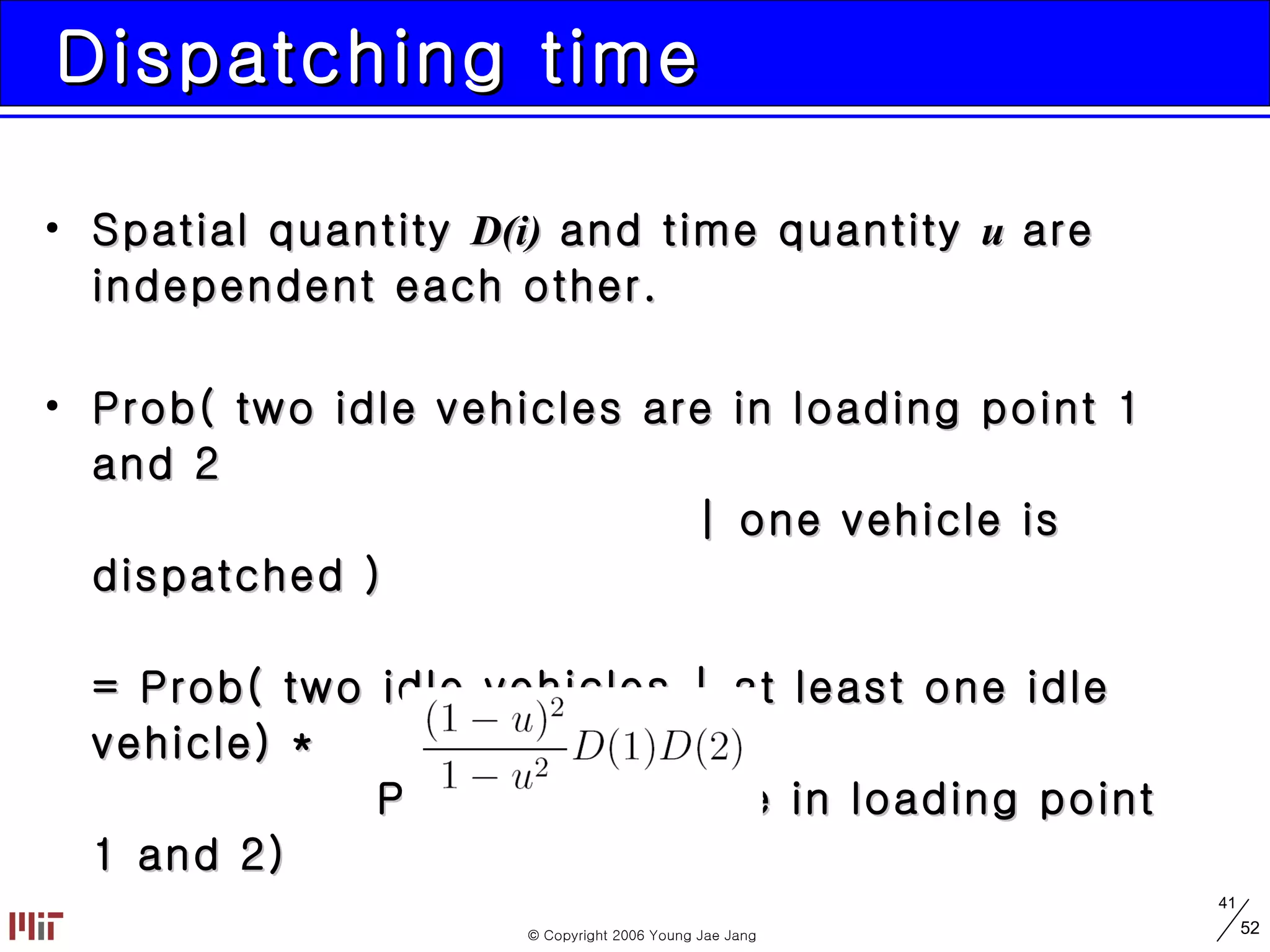

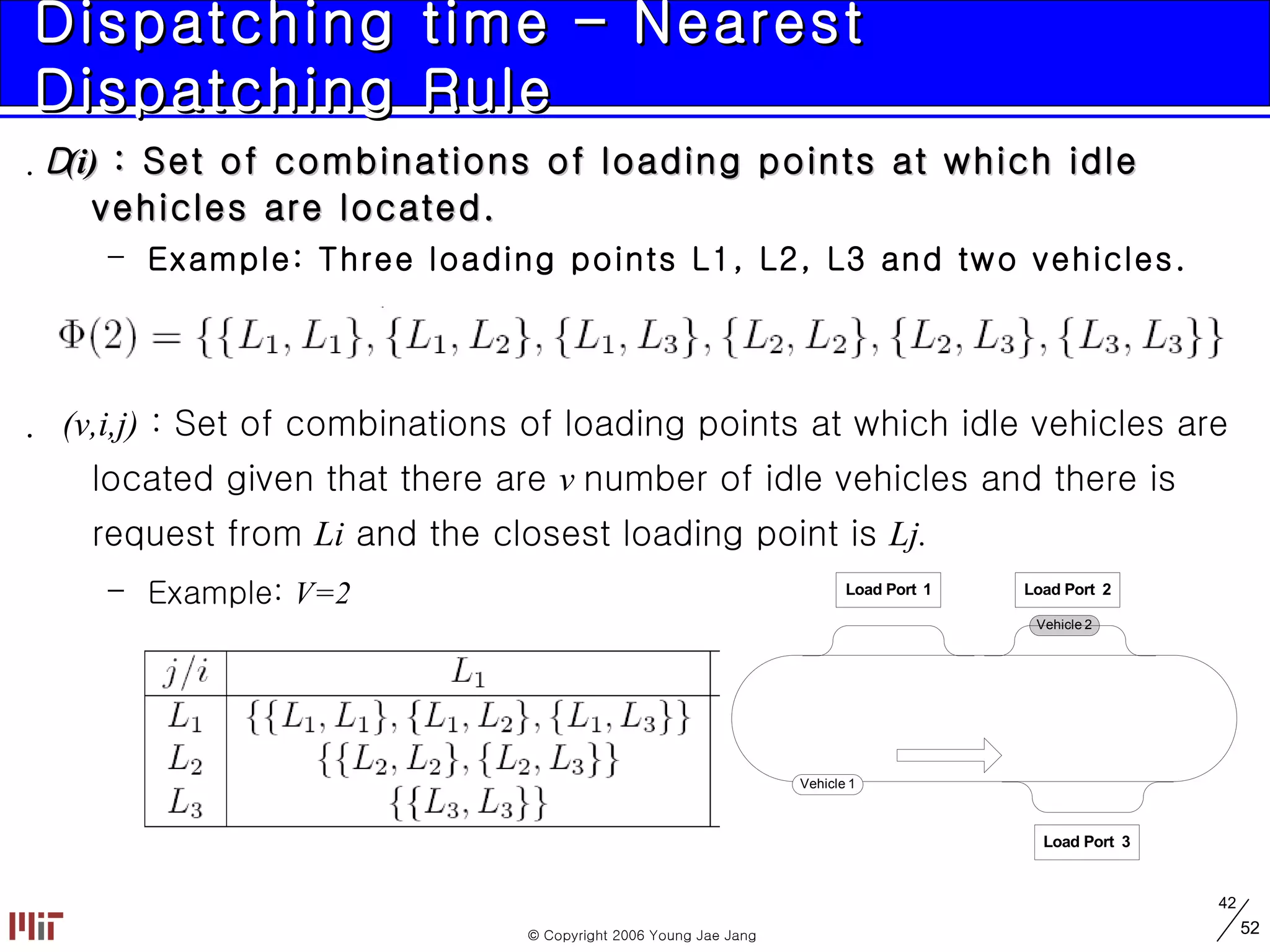

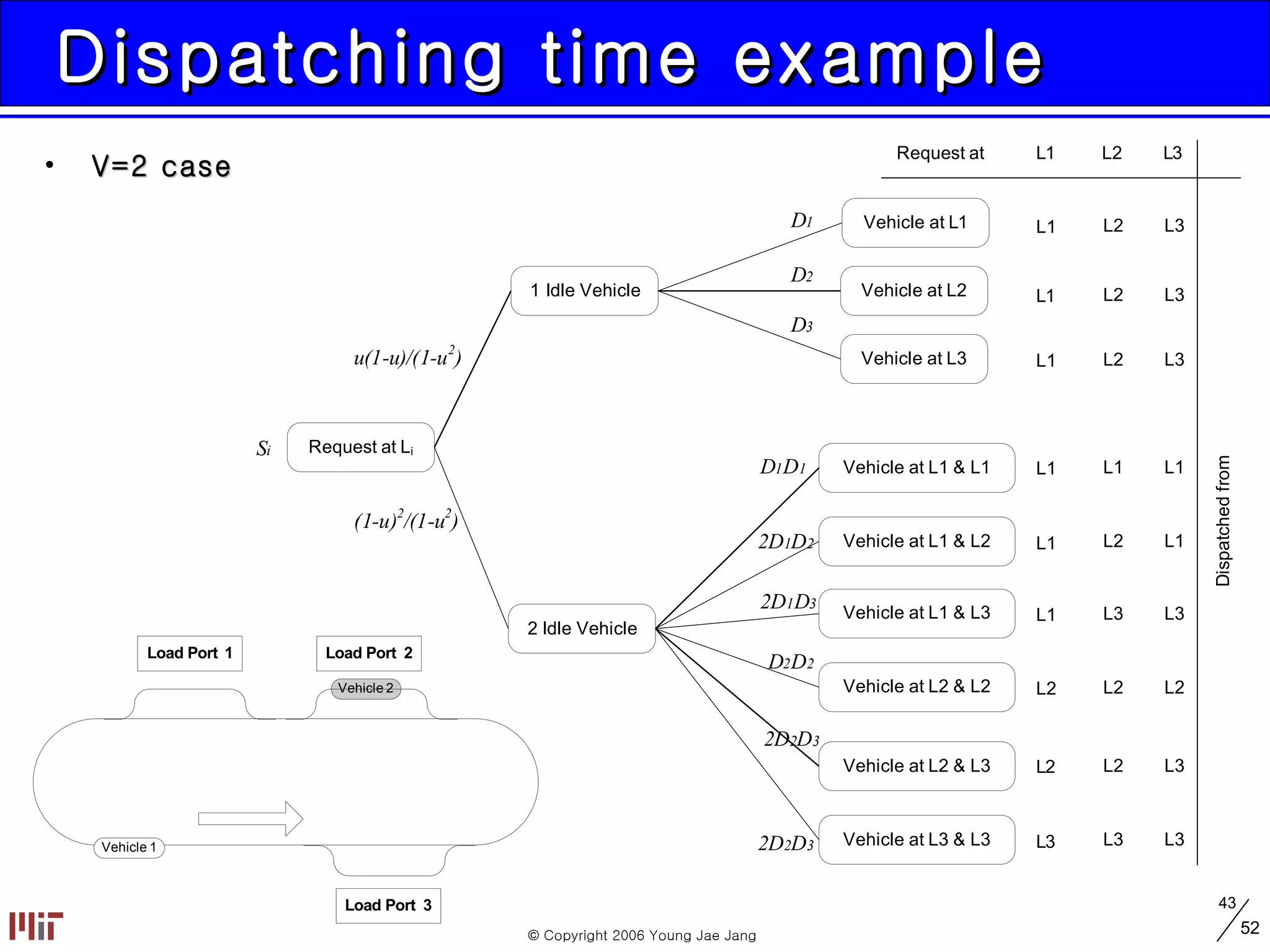

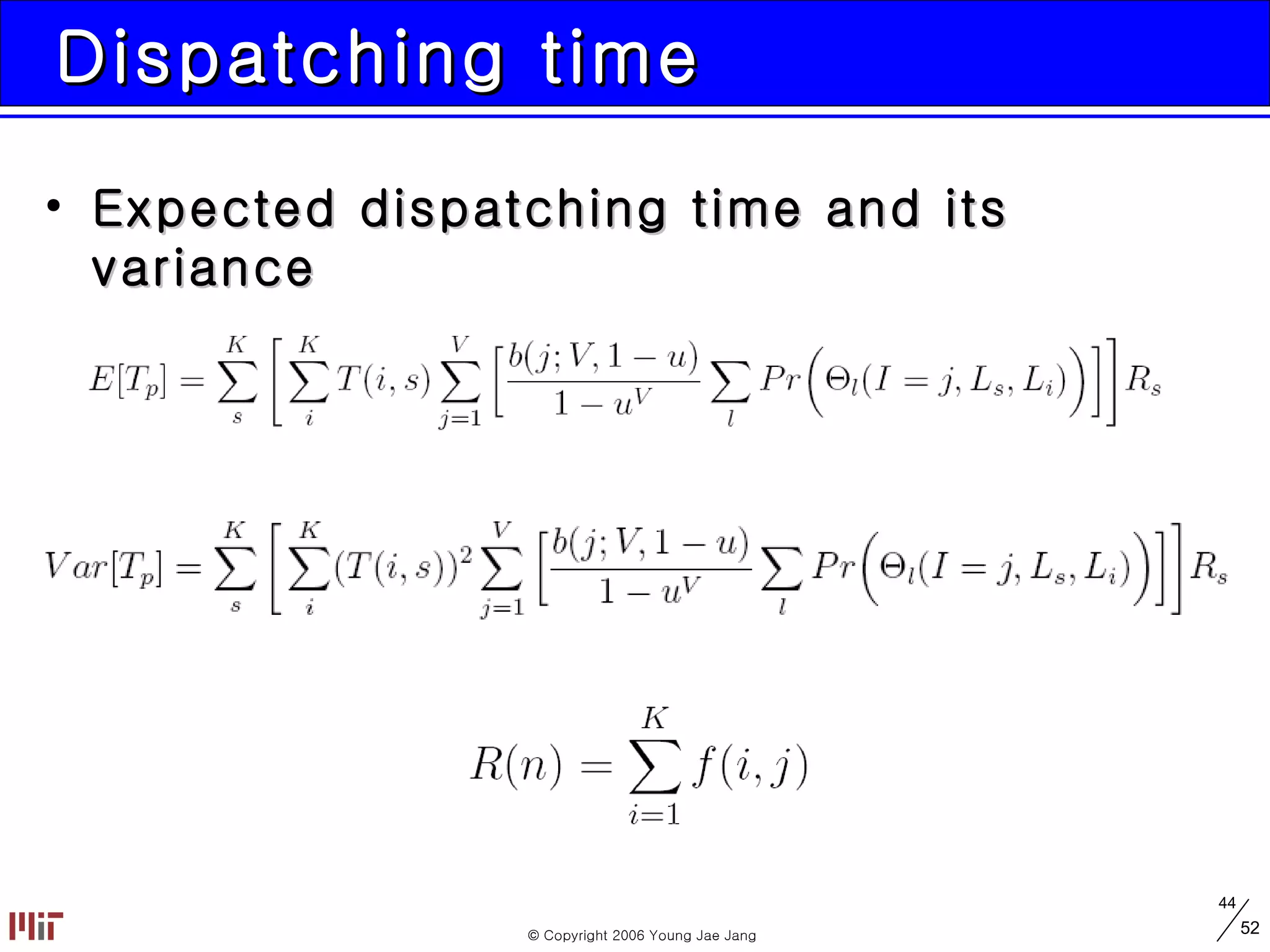

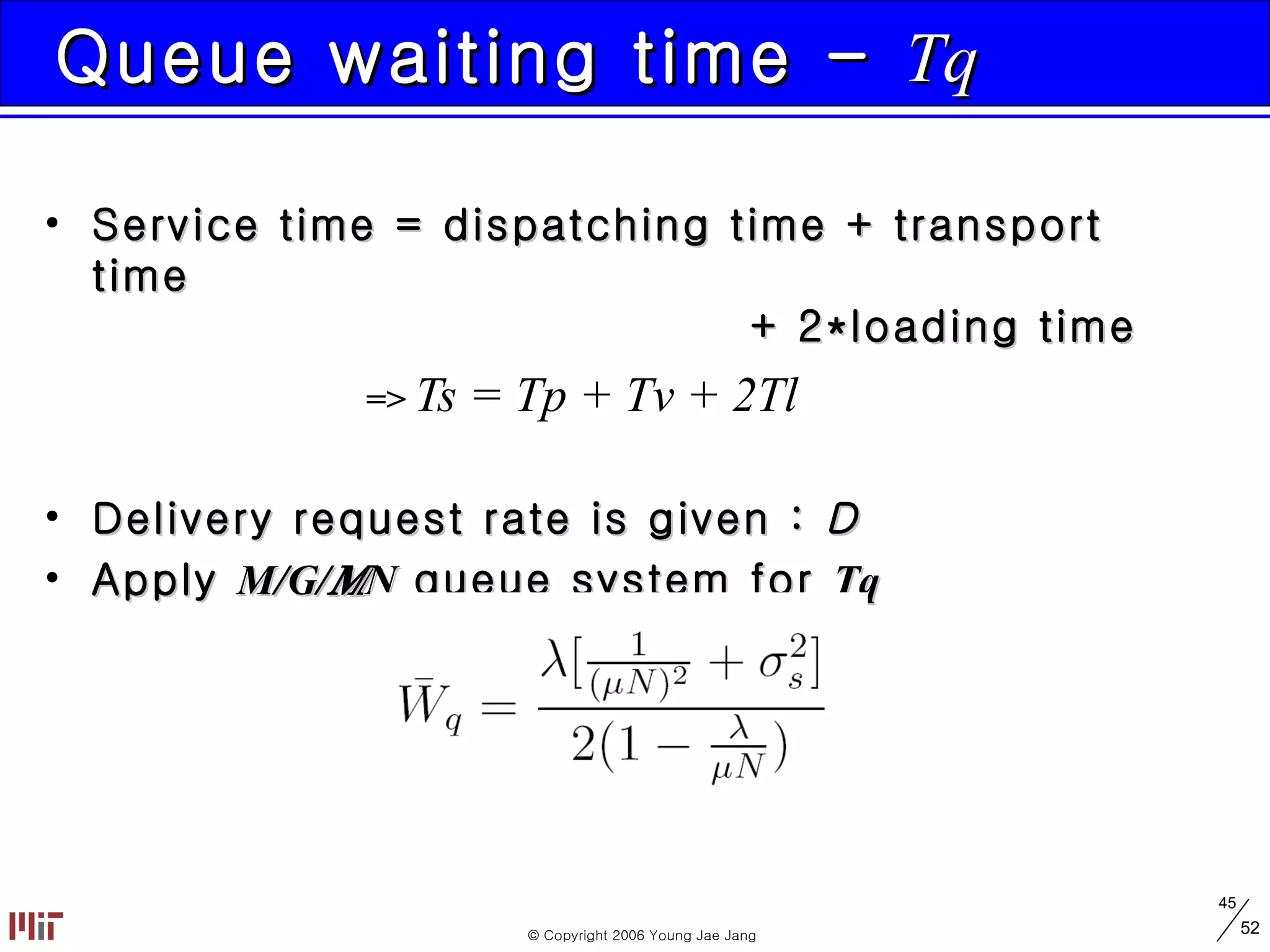

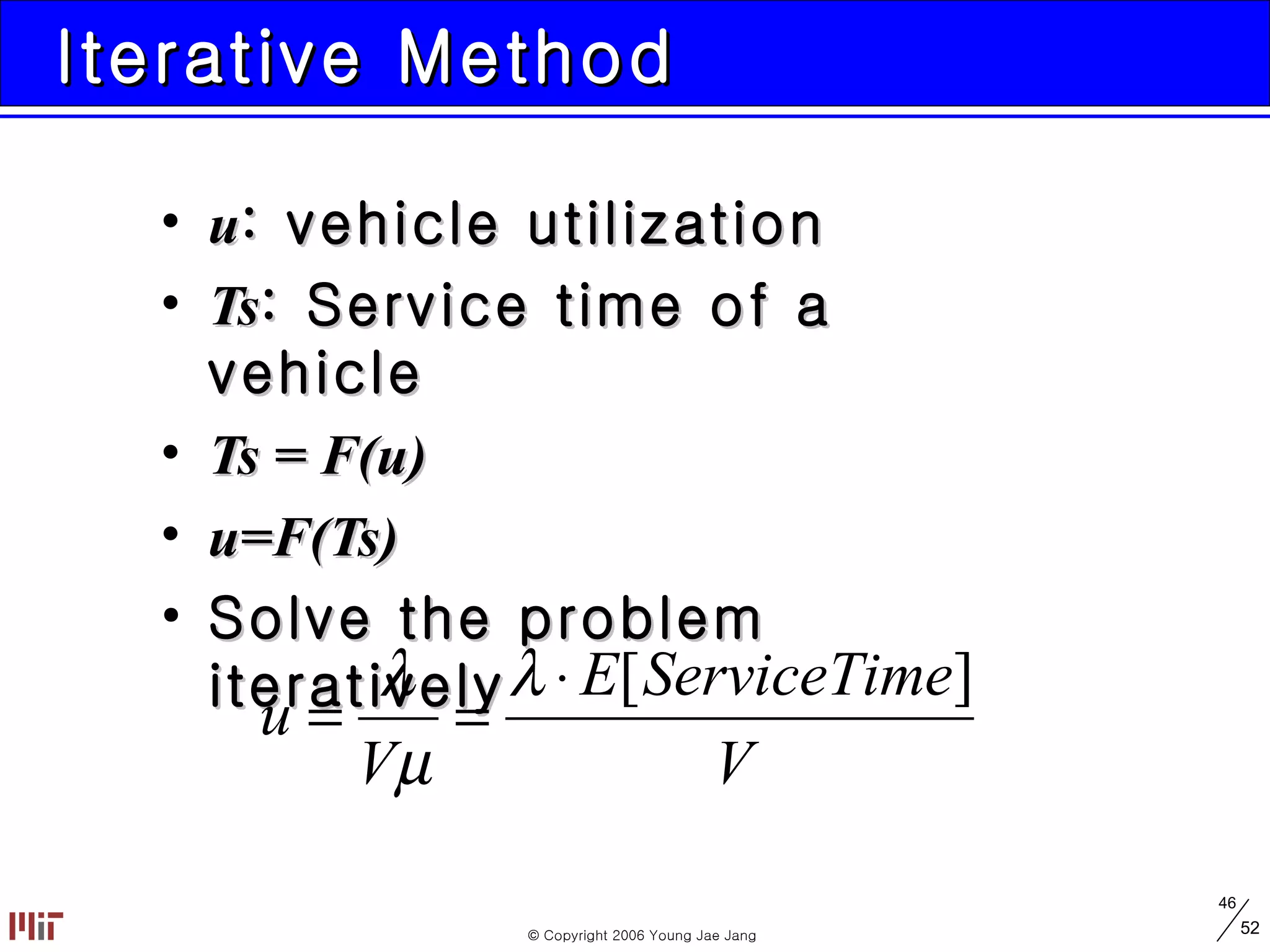

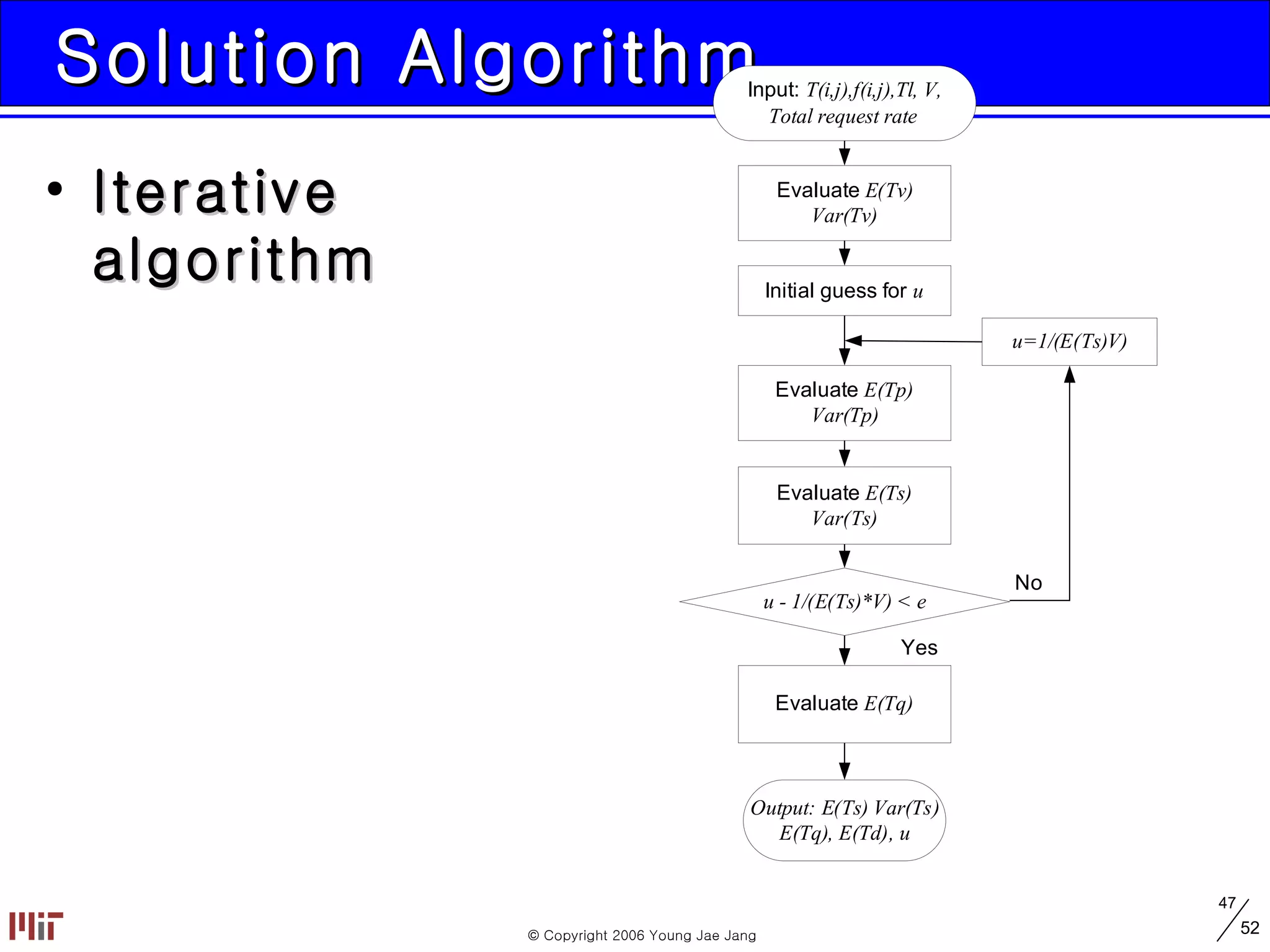

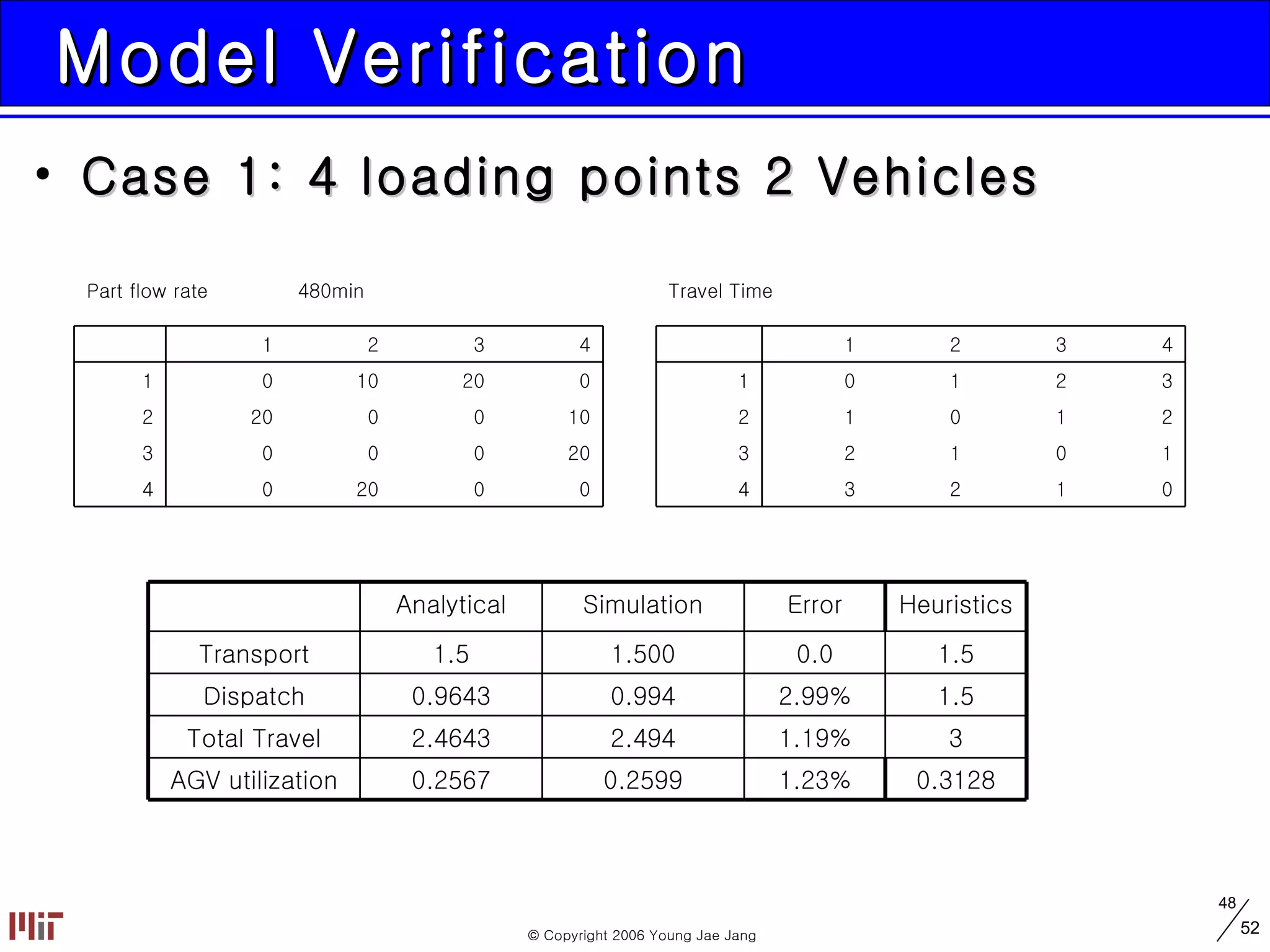

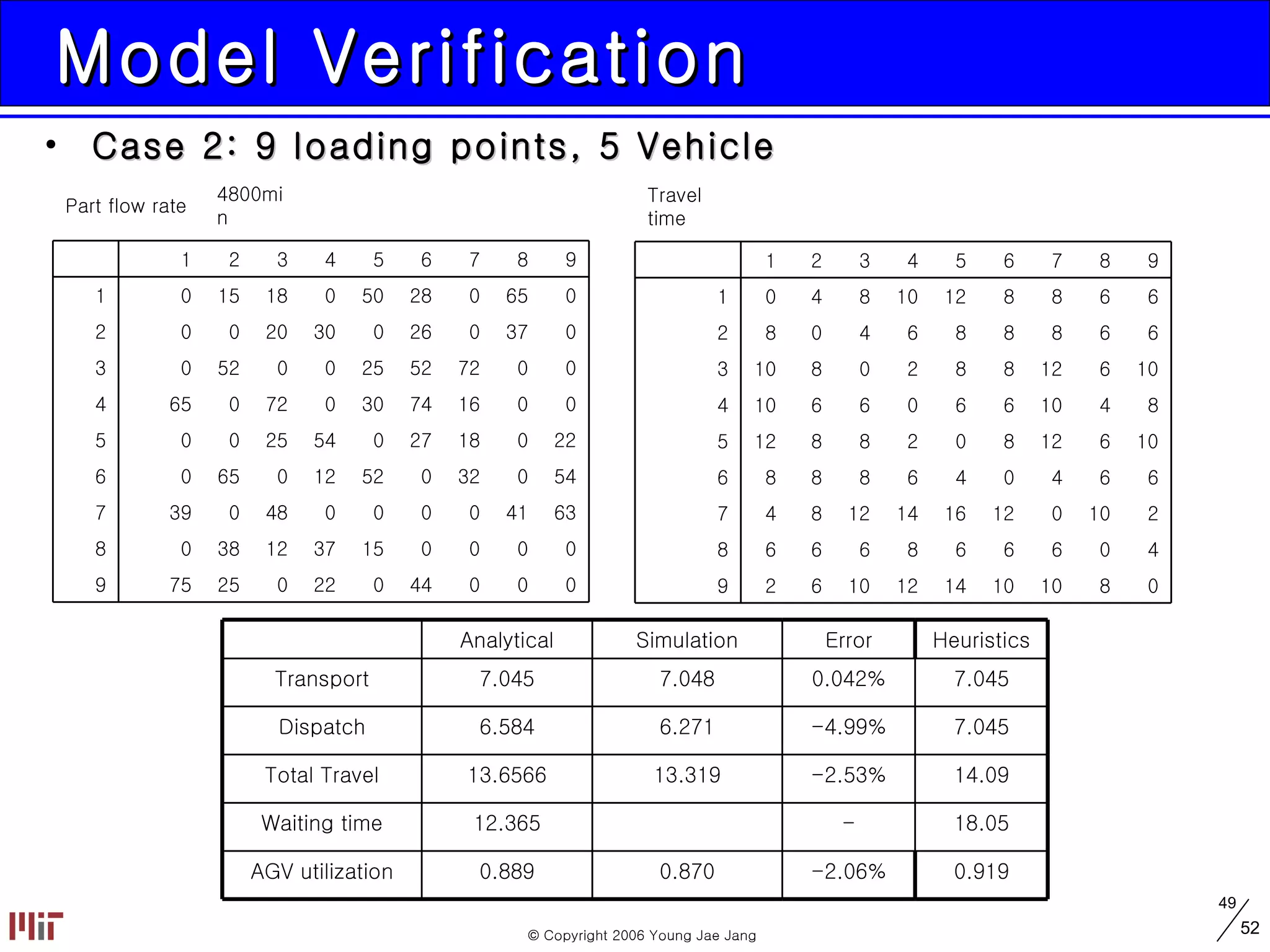

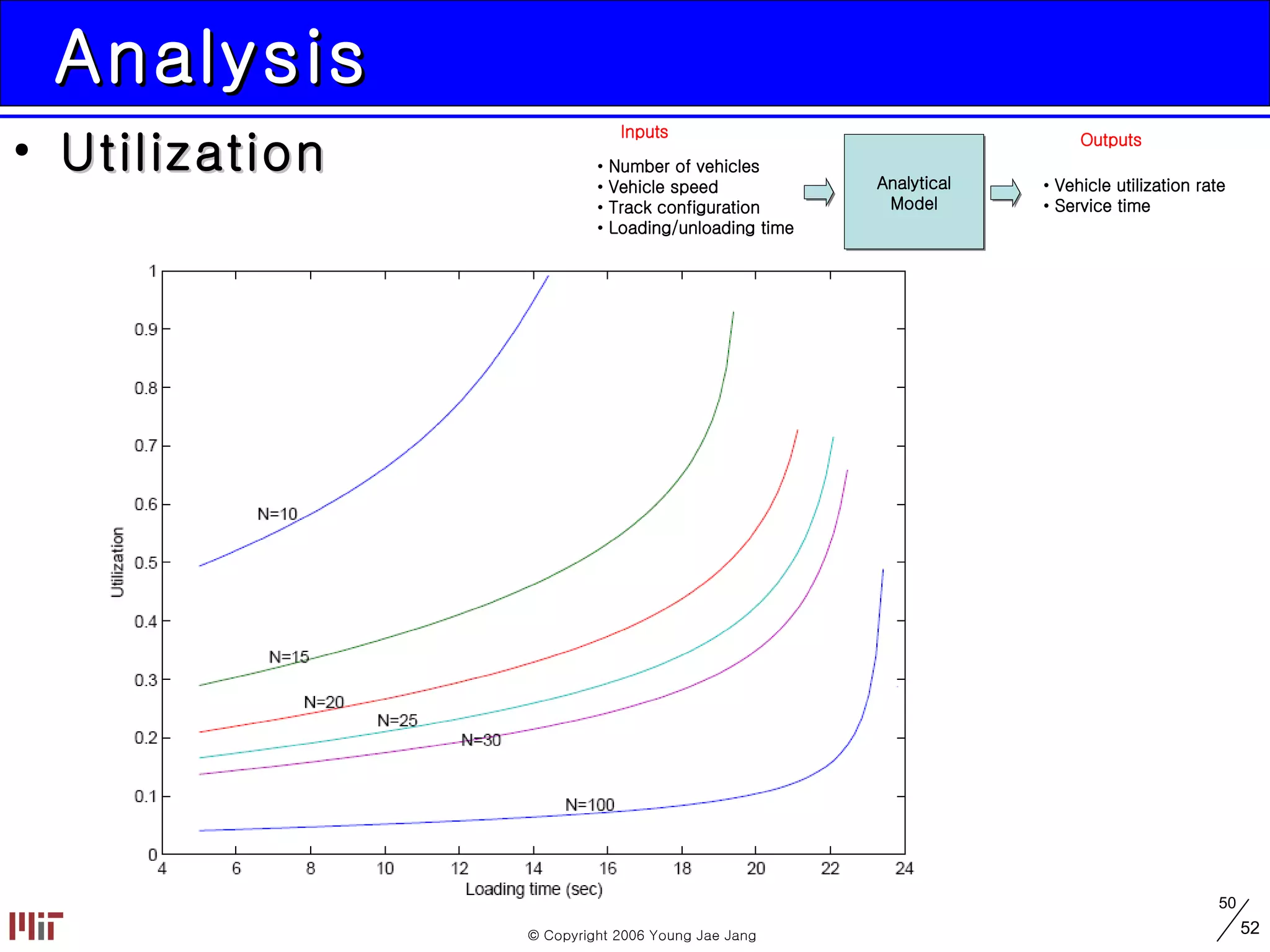

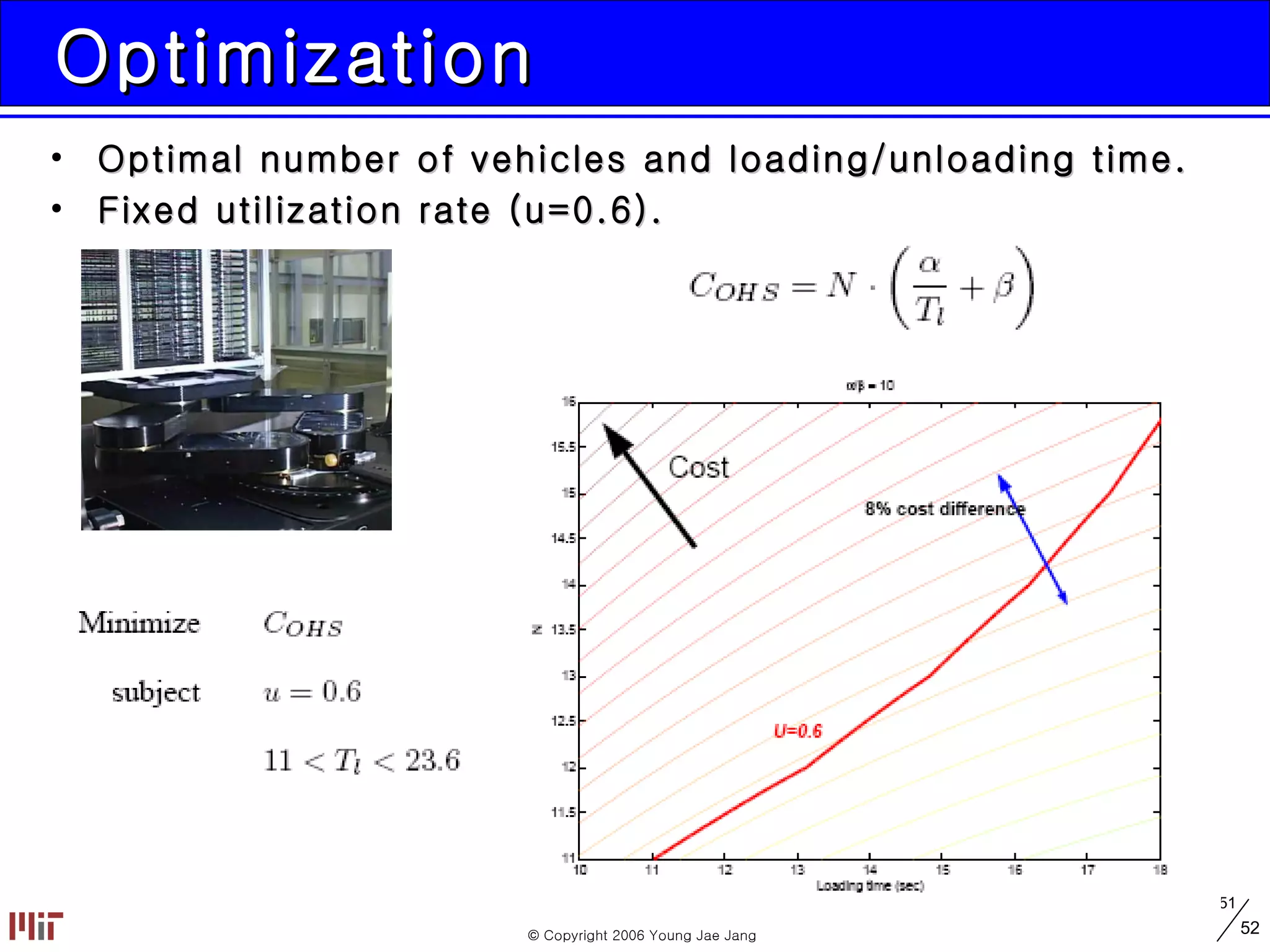

The document discusses automated material handling systems (AMHS) used in semiconductor and liquid crystal display (LCD) industries. It provides an overview of how AMHS are used in different stages of semiconductor wafer processing and LCD panel production. It also presents mathematical models to analyze AMHS, including queueing models to evaluate fleet size and vehicle utilization in AMHS.