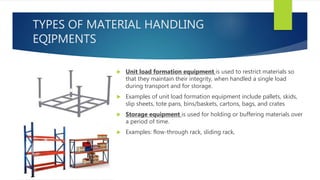

This document discusses material handling, which involves the movement, storage, and protection of materials. It describes the functions of material handling as lowering costs, reducing cycle times, and improving productivity and storage capacity. The principles of material handling emphasize planning, standardization, and ergonomics. Material handling can be manual, automated, or semi-automated. Key factors that influence material handling include production needs, equipment capabilities, and human elements. Common equipment includes conveyors, cranes, industrial vehicles, and auxiliary devices.