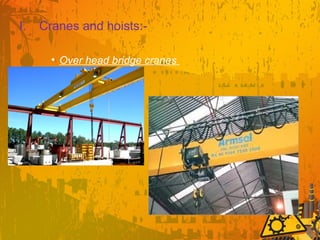

Material handling involves the efficient movement of materials and products throughout the supply chain. It aims to move the right materials to the right place at the right time in the most cost-effective manner. Material handling equipment includes transport equipment like conveyors, cranes, and automated guided vehicles; storage systems like racks and bins; and unitizing equipment. The goals of material handling are to reduce production costs, maintain quality, promote safety, and increase productivity through principles such as planning, system integration, simplification, gravity usage, space optimization, and automation.

![Material Handling

• Material handling is the function of

moving the right material to the right

place in the right time, in the right

amount, in sequence, and in the right

condition to minimize production

cost.

– The cost of MH estimates 20-25 of total

manufacturing labor cost in the United

States [The Material Handling Industry of America (MHIA)]](https://image.slidesharecdn.com/materialhandling-130502050250-phpapp01/85/Material-handling-2-320.jpg)