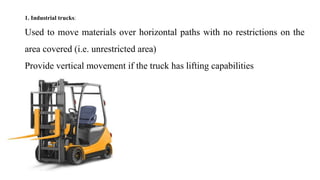

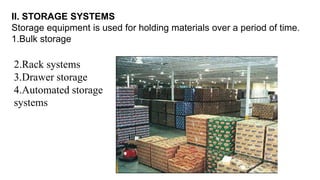

This document discusses the basics of material handling equipment. It defines material handling as the movement and storage of materials through the manufacturing process at the lowest cost. The objectives of material handling are to increase productivity and reduce costs while ensuring safety. There are four main categories of material handling equipment: transport equipment like forklifts and conveyor belts; storage systems like racks and bins; unitizing equipment like pallets and cartons; and identification/tracking systems like barcodes and RFID tags. The document provides examples of common equipment used in each category.