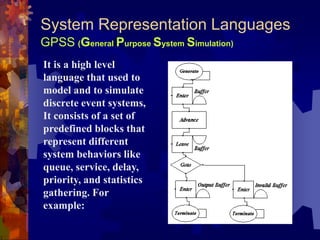

This document summarizes an integrated control system design tool that was developed to analyze and design intelligent control systems. The tool allows users to:

- Build interactive CAD models for control system design

- Incorporate various libraries and integrate popular AI techniques

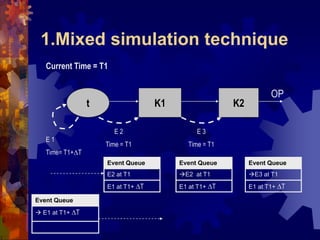

- Simulate systems using mixed continuous/discrete event simulation

- Represent systems with generalized Petri net and fuzzy system models

- Program using a new matrix-based language

- Model dead time elements flexibly

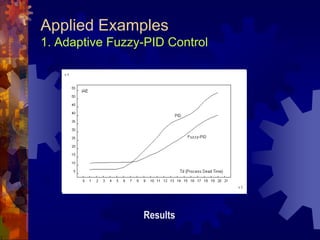

- Apply the tool to examples like adaptive fuzzy PID control and liquid level control

The document outlines the goals, background, achievements, related tools, and plans for future work regarding the development of the integrated intelligent control system design tool.

![System Representation Languages

Petri Net

It is a low level

language that used to

model and to simulate

discrete-event and

continuous-time

systems, It consists only

of tow predefined-

blocks [Place and

Transition], which are

enough to represent

very complex systems.

For example:](https://image.slidesharecdn.com/seminar-130426083428-phpapp01/85/Master-Thesis-Presentation-13-320.jpg)

![4. New Matrix Based Language

Power Matrix Script

Specification

Language with all structured languages features

Global variables, variables, constants

Control statement [If, for, while, switch]

Functions, subroutines

Support recursive calling

Variables and Constants are matrices or vectors

Support all matrix operations](https://image.slidesharecdn.com/seminar-130426083428-phpapp01/85/Master-Thesis-Presentation-32-320.jpg)

![4. New Matrix Based Language

Power Matrix Script

Feature

Support 9 data types [all C data types + complex],

this feature doesn't supported by Matlab script

Perform automatic data conversion

Function support any number of input and output

arguments

High Error protection against user mistakes

Libraries can be extended by functions and

subroutines and exported C functions

Automatically detect libraries

Integrated with the simulator

Encapsulated within single object](https://image.slidesharecdn.com/seminar-130426083428-phpapp01/85/Master-Thesis-Presentation-33-320.jpg)

![CAD Tool

Detail tool structure

element i sub-system j

Schematic Editor

System

Simulator

Power-Matrix Script Interpreter

Libraries Viewer Object Inspector

Value1P1

P2 Value2

… ...

Loaded

Libraries

Lib1 Lib2 Lib n

Library

Element

Definition

Environment Variables

Definition

Environment

Variables

Runtime Variables

Control CenterCommand Line Interpreter

Syntax/Script Editor

A = [1 2 3]

B= C + D

IF(A>PI/2)

B=C+D;

END;

A

Others](https://image.slidesharecdn.com/seminar-130426083428-phpapp01/85/Master-Thesis-Presentation-43-320.jpg)

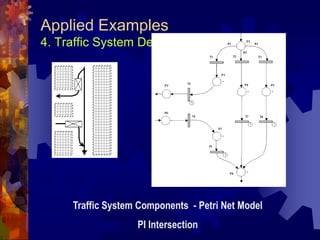

![Applied Examples

4. Traffic System Design Using Petri-Nets

Results

Input car generators [T=10,W=1] for each road

Simulation Time: 10000 second

Results:

Model 1 Model 2

Average Queue Length 3.067 0.1748

Average System Capacity 61.77 15.5

Case Study 1: Low Traffic

Input car generators [T=2,W=1] for each road

Simulation Time: 10000 second

Results:

Model 1 Model 2

Average Queue Length 466 0.8722

Average System Capacity 7500 77.9308

Case Study 2: Heavy Traffic](https://image.slidesharecdn.com/seminar-130426083428-phpapp01/85/Master-Thesis-Presentation-69-320.jpg)

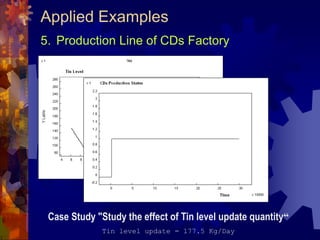

![Applied Examples

5. Production Line of CDs Factory

• Factory contains following production lines

• [Disk, Upper Cover, Down Cover, Holder ] Lines

• Assembly and Covering Line produce complete CD

• Packaging into small Boxes Line

• Packaging into Large Cartons Line

• Lines separated by buffers

• Input martial [Plastic Powder, Tin , Plastic Cover, Labels,

Small Boxes, Large Cartons] is stored in input buffers](https://image.slidesharecdn.com/seminar-130426083428-phpapp01/85/Master-Thesis-Presentation-70-320.jpg)

![Related Tools

GPSS-World

Simulator supports only standard GPSS language

Standard

Very fast simulation

Based on command mode interface [not visual]

Supported programming language is very week

Simulation Output in text format, no graphs, no

direct analysis can be applied

Advantage

Disadvantage](https://image.slidesharecdn.com/seminar-130426083428-phpapp01/85/Master-Thesis-Presentation-81-320.jpg)